Constant Temperature Tester for Measuring Conductor Resistance and Ensuring Accurate Performance

Understanding Constant Temperature Conductor Resistance Testers

In the realm of electrical engineering and materials science, the measurement of conductor resistance is crucial for assessing the performance of various materials and components. One of the sophisticated tools employed for this purpose is the Constant Temperature Conductor Resistance Tester. This device plays a vital role in ensuring the reliability and efficiency of electrical systems by delivering precise resistance values under controlled thermal conditions.

What is Conductor Resistance?

Conductor resistance refers to the opposition that a material offers to the flow of electric current. It is an intrinsic property influenced by various factors including the material type, length, cross-sectional area, and temperature. Accurate measurement of resistance is essential in applications ranging from power distribution to telecommunications, where any inefficiency can lead to significant losses and safety hazards.

The Importance of Temperature Control

Temperature is a key factor affecting resistance. According to Ohm's Law, the resistance of most conductive materials increases with temperature due to increased atomic vibrations that impede the flow of electrons. This variation can lead to misleading results if not controlled. Constant Temperature Conductor Resistance Testers mitigate this issue by maintaining a stable temperature throughout the testing process, ensuring that the measurements reflect the true resistive characteristics of the conductor without the interference of thermal fluctuations.

How Does a Constant Temperature Conductor Resistance Tester Work?

The operation of a Constant Temperature Conductor Resistance Tester revolves around several key components

1. Temperature Control System This system is typically fitted with a heating element and a temperature sensor, which work in tandem to maintain the desired temperature. Precise control is crucial, as even minor deviations can affect resistance readings.

2. Measurement Circuit The tester utilizes a measurement circuit that applies a known current through the conductor while simultaneously monitoring the voltage drop across it. Using Ohm's Law (V = IR), the resistance is calculated.

3. Recording and Output Modern testers often include data logging capabilities, allowing for the recording of resistance values over time or in response to varying temperature conditions. This data can be crucial for analyzing the behavior of materials under different thermal scenarios.

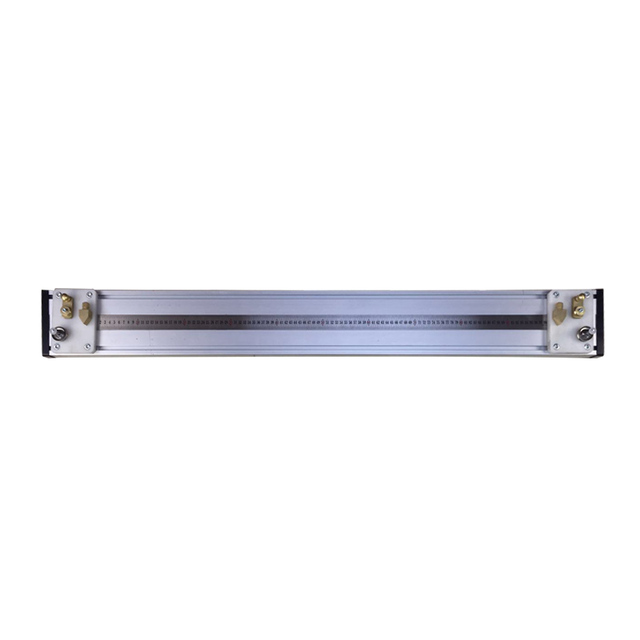

conductor resistance constant temperature tester

Applications of Constant Temperature Resistance Testing

Constant Temperature Conductor Resistance Testers are widely used across various industries, including

- Electrical Utilities They are instrumental in ensuring the reliability of power lines and transformers by evaluating the resistance of conductors used in transmission and distribution systems. - Material Science Researchers utilize these testers to study the conductivity of new materials, aiding in the development of advanced composites and conducting polymers.

- Electronics Manufacturing In the production of semiconductors and circuit boards, ensuring that materials meet specified resistance standards is critical for product performance.

Benefits of Using Constant Temperature Conductor Resistance Testers

Using a Constant Temperature Conductor Resistance Tester offers numerous advantages

- Accuracy By eliminating temperature fluctuations, the accuracy of resistance measurements is significantly enhanced, allowing for reliable data collection.

- Consistency Repeated tests under the same controlled conditions yield consistent results, which is essential for quality control and research validation.

- Enhanced Research and Development Engineers and scientists can confidently experiment with new materials, knowing that the resistance measurements will reflect their true conductive behavior.

Conclusion

In conclusion, Constant Temperature Conductor Resistance Testers are essential tools in the toolkit of electrical engineers and material scientists. By offering precise control over temperature, these testers enable accurate resistance measurements, which are pivotal in ensuring the integrity and efficiency of electrical systems. As industries continue to evolve, the role of these testers will only become more pronounced, driving advancements in technology and material science. Their application not only enhances safety and performance but also fosters innovation in the development of new conductive materials that can meet the demands of modern electrical systems.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy