Constant Temperature Tester for Conductor Resistance Measurement at Factory Standards

The Importance of Conductors and Resistance Testing in Electrical Engineering

In the realm of electrical engineering, the performance and reliability of electrical conductors are paramount. One of the critical factors that contribute to the efficient functioning of these conductors is their resistance. Understanding and measuring the resistance of electrical conductors at a constant temperature is essential for ensuring the safety and efficiency of electrical systems. This is where the significance of the conductor resistance constant temperature tester comes into play.

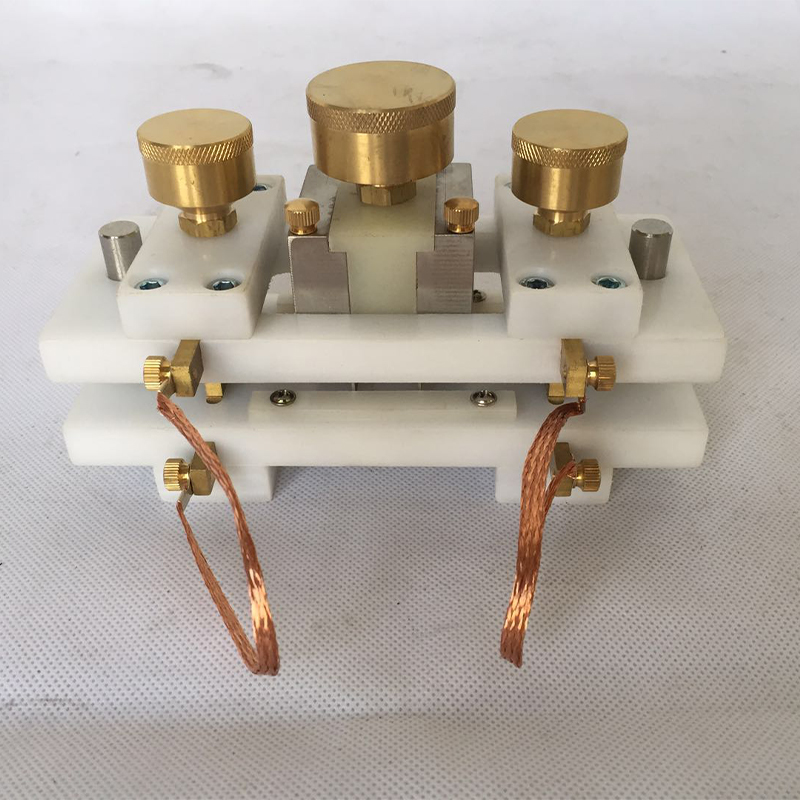

A conductor resistance constant temperature tester is a specialized device used to measure the resistance of conductive materials accurately. This device operates under the principle that the resistance of a conductor can change with temperature. Consequently, to obtain precise measurements, it is essential to maintain a constant temperature throughout the testing process. This minimizes fluctuations and external influences that could impact the readings, allowing for more reliable and consistent results.

The functionality of this tester is particularly vital in various applications, ranging from electrical installations in buildings to industrial electrical systems. For instance, low resistance measurements can indicate potential issues such as poor connections, which can lead to overheating and ultimately result in circuit failures. Therefore, routine testing with a resistance tester helps identify these issues early, allowing for timely maintenance and preventing costly downtimes.

Moreover, the accuracy of resistance measurements contributes directly to the overall performance of electrical installations. High resistance can lead to significant power losses in transmission lines, which is not only inefficient but also detrimental to the operational lifespan of electrical components. By ensuring that the resistance levels remain within acceptable limits, engineers can optimize the performance of the electrical system and enhance its longevity.

conductor resistance constant temperature tester factory

Manufacturers and factories that produce electrical components recognize the importance of rigorous testing. Many of these facilities are equipped with conductor resistance constant temperature testers to ensure that every batch of components meets the required specifications. This not only guarantees product quality but also enhances the credibility and reputation of the manufacturer, as customers seek reliable and high-performing electrical products.

In addition to traditional applications, the emergence of renewable energy technology has underscored the importance of resistance testing. With the increasing integration of solar panels and wind turbines into the power grid, the need for efficient conductors has become even more critical. These energy sources can be sensitive to resistance variations, and thus, continuous monitoring and testing of resistant levels become essential for maximizing energy efficiency.

Furthermore, advancements in testing technology have led to the development of more sophisticated resistance testers that are capable of providing real-time data and analytics. These devices come equipped with features such as digital displays, data logging capabilities, and connectivity options for easy data transfer. As a result, electrical engineers can make informed decisions based on precise data analysis, leading to better designs and implementations.

In conclusion, the role of a conductor resistance constant temperature tester is crucial in maintaining the efficiency and reliability of electrical systems. By ensuring accurate resistance measurements, industries can mitigate risks, enhance performance, and contribute to safer electrical environments. As technology continues to evolve, the importance of such testing methods will only increase, emphasizing the need for continued investment in quality testing equipment across various sectors.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy