conductor resistance constant temperature test exporter

Understanding Conductor Resistance at Constant Temperature Insights and Applications

In the field of electrical engineering, one of the critical parameters that engineers and technicians take into account when designing and testing electrical components is conductor resistance. Conductor resistance is a measure of how much a conductor opposes the flow of electric current. At a constant temperature, this resistance plays a pivotal role in determining the efficiency and performance of electrical systems. This article delves into the concept of conductor resistance, the importance of constant temperature testing, and the role of exporters in supplying these crucial testing services and equipment.

The Basics of Conductor Resistance

Conductor resistance is influenced by several factors, including the material properties, length of the conductor, and its cross-sectional area. The relationship can be mathematically defined by the formula

\[ R = \rho \frac{L}{A} \]

where \( R \) is the resistance, \( \rho \) is the resistivity of the material, \( L \) is the length of the conductor, and \( A \) is the cross-sectional area. Conductors with lower resistivity, such as copper and aluminum, are commonly used in electrical applications due to their ability to carry current efficiently. Understanding conductor resistance is essential for system designers to minimize power losses and ensure high performance.

Constant Temperature Testing

One of the most crucial aspects of testing conductor resistance is maintaining a constant temperature. Temperature variations can significantly affect resistance readings due to the temperature coefficient of resistivity that most materials exhibit. As temperature increases, resistivity generally increases for conductive materials, leading to higher resistance. Therefore, conducting resistance tests at a stable, controlled temperature is essential for accurate results.

Constant temperature testing allows engineers to establish baseline resistance values for conductors, ensuring that any deviations in performance can be attributed to factors other than temperature variations. It is particularly important in applications where precise control of electrical properties is critical, such as in high-frequency circuits, power transmission lines, or sensitive electronic devices.

conductor resistance constant temperature test exporter

The Role of Exporters in Conductor Resistance Testing

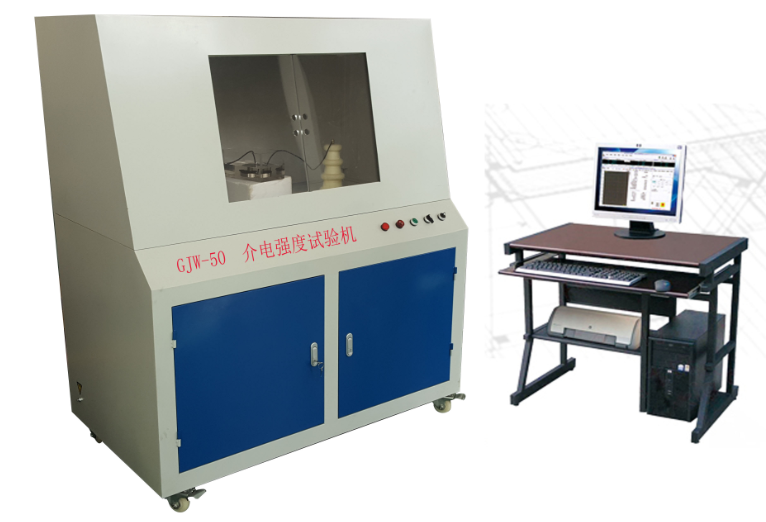

With the growing demand for high-quality electrical components and systems, the role of exporters who specialize in conductor resistance testing has become more important than ever. These exporters provide a range of testing services and equipment that adhere to industry standards and regulations. This includes specialized instruments for measuring resistance, such as Wheatstone bridges, ohmmeters, and multimeters designed for high precision.

Exporters often not only supply testing equipment but also offer training and support services. This ensures that engineers, technicians, and researchers can effectively utilize the tools for accurate readings. Additionally, many exporters are involved in the research and development of advanced testing methodologies that allow for more reliable and efficient assessments of conductor resistance.

Applications Across Industries

The implications of accurately measuring conductor resistance at a constant temperature are far-reaching. Industries such as telecommunications, aerospace, automotive, and renewable energy rely heavily on components that require precise resistance measurements to function correctly. For instance, in electric vehicles, the resistance of wiring and connections can directly impact battery performance and overall energy efficiency.

Furthermore, in renewable energy systems like solar panels and wind turbines, conductor resistance tests are essential for ensuring that the energy transfer processes operate efficiently. Components must be thoroughly tested to minimize losses, increase longevity, and optimize performance.

Conclusion

In conclusion, understanding conductor resistance at constant temperature is essential for the development and maintenance of reliable electrical systems. Accurate testing plays a crucial role in ensuring that systems perform efficiently and meet safety standards. As the demand for high-quality electrical components continues to grow, exporters providing specialist testing services and equipment will play an increasingly vital role in supporting industries that rely on electrical conductors. The collaboration between manufacturers, engineers, and exporters will ultimately drive innovation and enhance the reliability of electrical systems in an ever-evolving technological landscape.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy