conductor resistance constant temperature test exporter

Understanding Conductor Resistance Constant Temperature Testing and Its Importance

In the realm of electrical engineering and materials science, the resistance of conductors is a critical parameter that influences the efficiency and performance of electrical systems. A conductor's resistance is not a fixed value; it can vary based on several factors, including temperature. This article delves into the concept of conductor resistance, the significance of constant temperature tests, and their implications for exporters and manufacturers in the industry.

What is Conductor Resistance?

Conductor resistance refers to the opposition that a material offers to the flow of electric current. It is determined by the material's intrinsic properties, such as resistivity, length, and cross-sectional area. The resistance R of a conductor can be calculated using the formula

\[ R = \rho \frac{L}{A} \]

Where - \( R \) = Resistance (Ohms) - \( \rho \) = Resistivity of the material (Ohm-meters) - \( L \) = Length of the conductor (meters) - \( A \) = Cross-sectional area (square meters)

The resistivity of materials changes with temperature, which introduces the need for conducting tests at constant temperatures.

The Significance of Constant Temperature Testing

Constant temperature tests are essential for accurately evaluating the resistance of conductors. Temperature can significantly affect the resistive properties of materials, especially metals. As temperature increases, the atomic vibrations within the material also increase, leading to a higher frequency of collisions among charge carriers. This phenomenon generally results in increased resistance.

To obtain reliable and consistent data regarding a conductor’s resistance, it is crucial to conduct tests at a controlled temperature

. Constant temperature conditions allow exporters and manufacturers toconductor resistance constant temperature test exporter

1. Ensure Consistency By testing at a constant temperature, companies can ensure that the resistance values obtained are representative of the material's behavior under standard conditions. This is particularly important when materials are being compared to established benchmarks or specifications.

2. Compliance with Standards Many industries adhere to strict electrical standards that dictate specific testing conditions. Constant temperature testing helps manufacturers meet these regulatory requirements, which is essential for product certification and marketability.

3. Enhance Product Quality Understanding how resistance varies with temperature allows manufacturers to optimize their production processes and materials. This results in higher-quality products that perform better under varying operating conditions.

4. Facilitate International Trade For exporters dealing with international markets, compliance with global standards for electrical components is critical. Constant temperature resistance testing provides a universal metric that can be recognized globally, facilitating smoother trade operations.

Exporter Implications

For exporters in the electrical component industry, understanding and implementing constant temperature resistance tests is crucial. Not only do these tests help in ensuring product quality and compliance, but they also assist in building trust with clients and stakeholders. Providing data from constant temperature tests can serve as proof of a product’s reliability and performance, which is a vital consideration for buyers in various sectors such as telecommunications, automotive, and consumer electronics.

Furthermore, exporters must invest in state-of-the-art testing equipment to conduct these assessments accurately. Advanced testing facilities that can maintain constant temperatures will enable exporters to produce high-quality data, thus enhancing their competitive edge in the market.

Conclusion

Conductor resistance is a fundamental aspect of electrical engineering that has far-reaching implications, particularly for exporters. By prioritizing constant temperature resistance testing, manufacturers can ensure product reliability, uphold quality standards, and foster international trade relationships. As technology evolves and the demand for efficient electrical systems grows, the importance of rigorously assessing conductor resistance cannot be overstated. As a result, embracing these testing methodologies is not just a regulatory requirement but a strategic imperative for success in the ever-evolving electrical market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

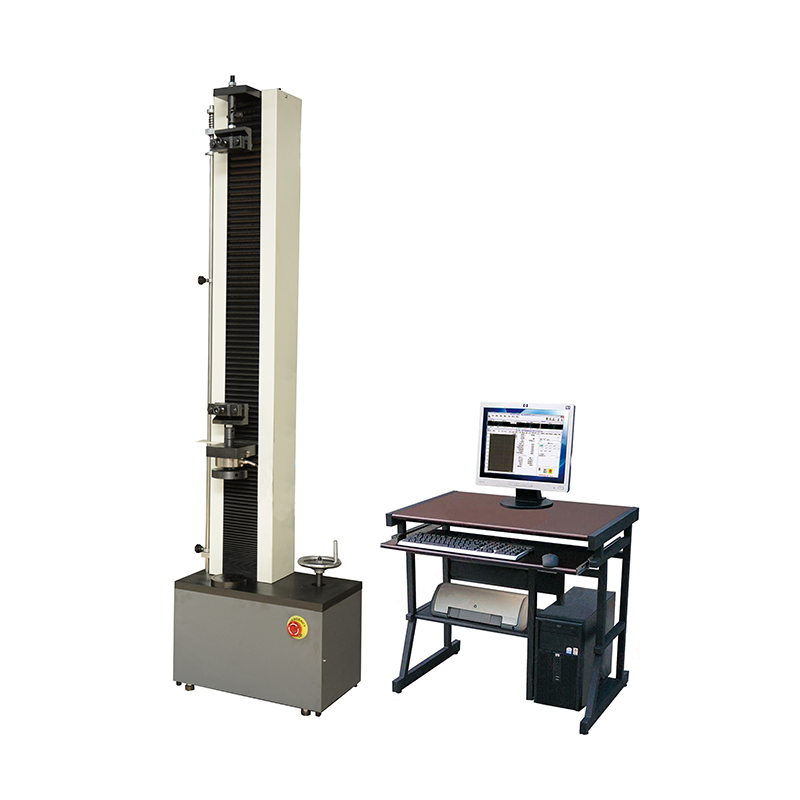

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy