conductor resistance constant temperature test exporters

Understanding Conductor Resistance Constant Temperature Test for Exporters

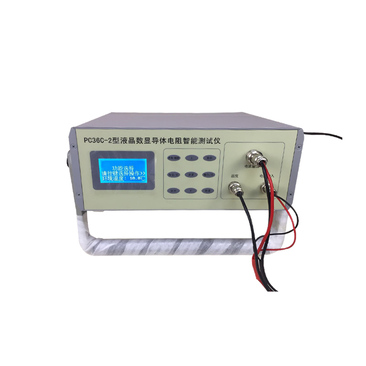

In the realm of electrical engineering and power distribution, the performance of electrical conductors is crucial. One key aspect of their performance is resistance, which can impact the efficiency and safety of electrical systems. For exporters dealing with electrical materials, understanding the conductor resistance constant temperature test is essential for ensuring product quality and compliance with international standards.

What is the Conductor Resistance Test?

The conductor resistance test measures the electrical resistance of a conductor, which is vital for determining the effectiveness of electrical transmission. Resistance is influenced by various factors, including the conductor material, length, cross-sectional area, and temperature. The resistance of a conductor typically increases with temperature, making it important to conduct these tests under controlled conditions.

A constant temperature resistance test is performed to ensure that temperature variations do not influence the results. This is particularly important for exporters who must guarantee that their products will perform consistently across different environments and operating conditions.

Importance for Exporters

For exporters in the electrical sector, ensuring that their conductors meet stringent international standards is a top priority. The conductor resistance constant temperature test allows exporters to

1. Ensure Quality and Compliance Meeting global standards such as IEC (International Electrotechnical Commission) and ASTM (American Society for Testing and Materials) is crucial. Conducting resistance tests ensures that products comply with these guidelines, thereby enhancing reputation and marketability.

2. Enhance Performance Reliability By understanding how resistance varies at different temperatures, exporters can provide more reliable products. This is particularly critical in applications where performance is non-negotiable, such as in power plants, public utilities, and industrial facilities.

conductor resistance constant temperature test exporters

3. Reduce Costs Testing and verifying the resistance of conductors at constant temperature can help identify potential issues before they escalate, reducing the risk of failure in the field, which in turn minimizes costly repairs or replacements.

The Testing Process

The constant temperature resistance test typically involves the following steps

1. Preparation The conductor sample is prepared, ensuring that it is clean and free from any surface contaminants that may affect measurement.

2. Temperature Control The sample is placed in a controlled environment that maintains a constant temperature, usually at ambient levels or at a specific test temperature.

3. Measurement Using a precision ohmmeter, the resistance is measured across the conductor. This process is repeated multiple times to ensure accuracy and consistency.

4. Analysis The collected data is analyzed to determine if the resistance falls within acceptable limits. Any deviations can indicate issues with the material or manufacturing processes.

Conclusion

For exporters in the electrical materials market, the conductor resistance constant temperature test is an essential procedure that underpins the integrity and reliability of their products. By prioritizing these tests, exporters not only adhere to global standards but also foster trust with clients and stakeholders. Continuous investment in testing technologies and adherence to best practices will pave the way for success in an increasingly competitive market. Ensuring that conductors are evaluated for resistance at a constant temperature is key to achieving long-term operational efficiency and customer satisfaction.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy