Constant Temperature Testing of Conductor Resistance in Factory Settings for Performance Evaluation

Understanding Conductor Resistance Constant Temperature Testing in Factories

In the world of electrical engineering and manufacturing, testing the resistance of conductors at a constant temperature is critical. This process, known as conductor resistance constant temperature testing, plays a vital role in ensuring that electrical components perform efficiently and safely. This article explores the significance of this testing method, its applications, and its implications for the industry.

The Importance of Conductor Resistance

Conductors are materials that allow the flow of electrical current, and their resistance is a crucial parameter that affects the performance of electrical systems. Resistance can influence factors such as power loss, energy efficiency, and heat generation. Higher resistance in conductors can lead to excessive heat buildup, resulting in potential failure of electrical equipment, reduced lifespan, and safety hazards. Therefore, understanding and measuring conductor resistance are essential for maintaining optimal performance in electrical systems.

The Concept of Constant Temperature Testing

Constant temperature testing involves measuring the resistance of a conductor while maintaining a stable temperature environment. This is vital because resistance can vary with temperature; thus, obtaining an accurate reading requires precise control of thermal conditions. The most commonly used temperature for these tests is 20 degrees Celsius, a standard reference point in many industries.

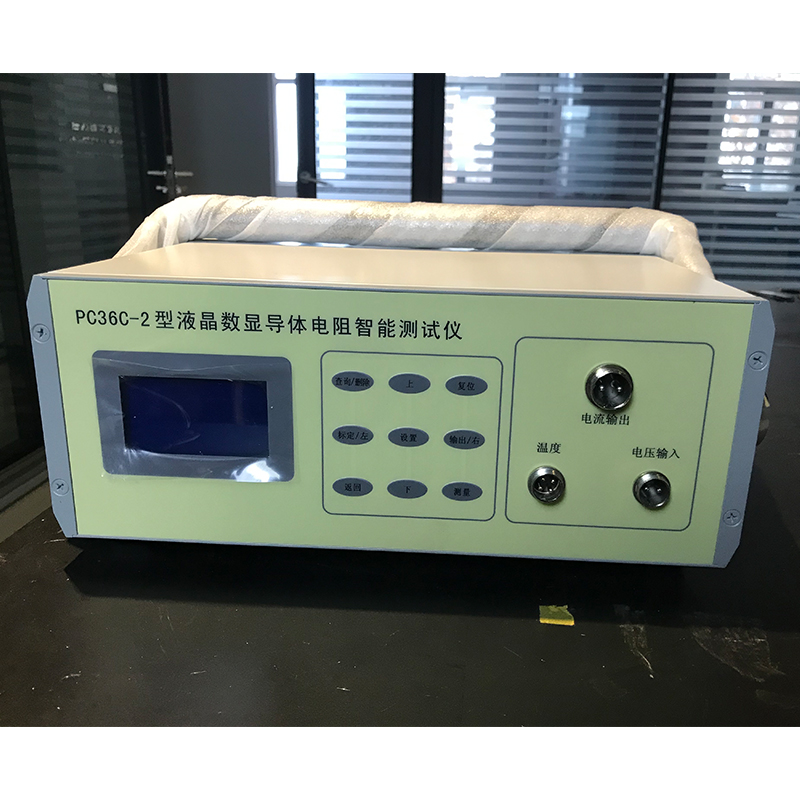

The procedure typically involves placing a conductor in a controlled environment where the temperature is regulated. Testing equipment such as ohmmeters or specialized resistance bridges is then used to measure the resistance values. This method ensures that the results are consistent and repeatable, providing reliable data for engineers and quality control personnel.

Applications in Industry

Conductor resistance testing finds its applications across various sectors, including power generation, transmission, and distribution systems, as well as in manufacturing electrical components. For instance

1. Electrical Utilities In public utilities, testing the resistance of overhead and underground conductors is essential for maintaining the reliability of power distribution networks. Regular testing helps identify anomalies that can lead to outages or equipment failures.

conductor resistance constant temperature test factory

2. Manufacturing In the manufacturing of electrical cables and components, constant temperature resistance testing is integrated into quality control processes. Ensuring that products meet resistance specifications prevents failure in the field and enhances customer satisfaction.

3. Electronics In the electronics sector, particularly in semiconductor manufacturing, the resistance of interconnects and conductive paths is measured to ensure minimal signal loss and efficient performance of electronic devices.

Quality Assurance and Safety

Carrying out conductor resistance constant temperature testing is also vital for compliance with safety standards and regulations. Organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) provide guidelines and standards for electrical testing. Compliance with these standards ensures that manufacturers produce safe and reliable electrical components.

Moreover, regular resistance testing can serve as a preventive maintenance measure. By identifying potential failures before they occur, companies can avoid costly downtime, enhance safety, and maintain operational integrity.

Challenges and Considerations

While conductor resistance constant temperature testing is crucial, it is not without challenges. Achieving and maintaining a constant temperature requires sophisticated equipment and skilled personnel. Variability in environmental conditions, such as humidity and external temperature fluctuations, can also influence test results.

Furthermore, the precision of measuring instruments plays a significant role in the accuracy of resistance readings. It is essential for engineers and technicians to be trained in using these instruments properly to ensure reliable results.

Conclusion

In conclusion, conductor resistance constant temperature testing is an essential practice in the electrical manufacturing and utilities sectors. By ensuring that conductors maintain appropriate resistance levels, industries can enhance safety, efficiency, and reliability. As technology progresses and the demand for high-performing electrical systems increases, the significance of accurate testing methods will continue to grow. Emphasizing quality control and adherence to testing standards will ultimately lead to better outcomes, benefiting manufacturers and consumers alike. Understanding and implementing effective resistance testing protocols not only safeguards equipment and personnel but also reinforces the integrity of the electrical systems that power our world.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy