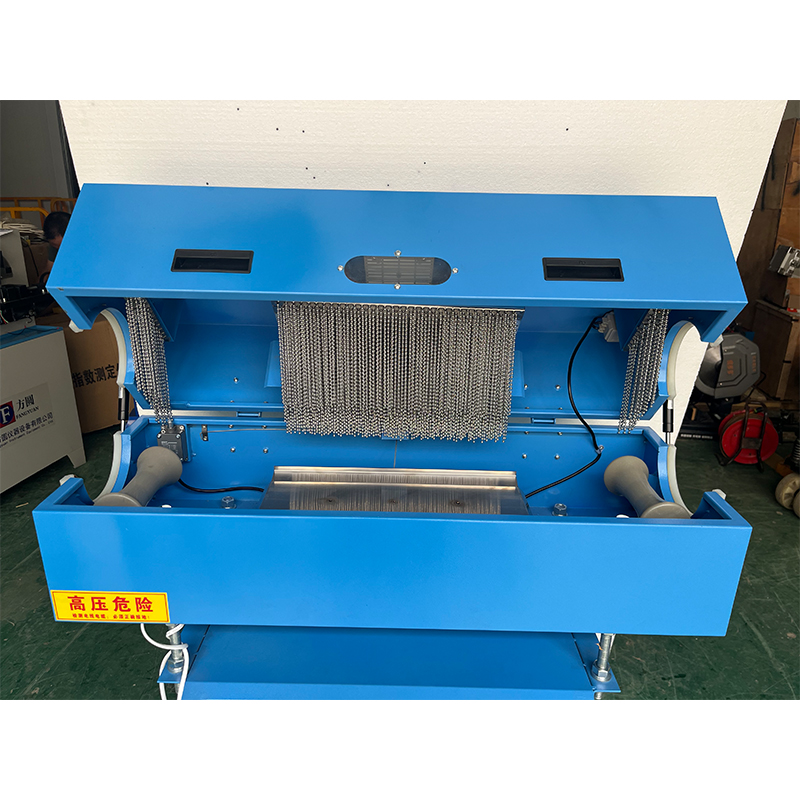

conductor resistance fixture

Understanding Conductor Resistance Fixtures Importance and Applications

In the world of electrical engineering and materials science, the measurement of conductor resistance is a critical task that impacts the performance, safety, and efficiency of electrical systems. To accomplish this effectively, engineers employ a specialized tool known as a conductor resistance fixture. This sophisticated device enables precise assessment of the electrical resistance of various conductors, which is vital for a multitude of applications.

At its core, a conductor resistance fixture serves as a testing apparatus that ensures accurate readings of resistance in wire, cables, and other conductive materials. The primary function of this fixture is to measure the DC resistance of these conductors, which is essential for determining their ability to carry electrical current without excessive power loss. In practical terms, high resistance can lead to overheating, increased energy consumption, and potential system failures—consequences that can be devastating in both industrial and residential applications.

One of the key components of a conductor resistance fixture is its ability to maintain consistent contact with the conductor. This is crucial because any variances in contact pressure or surface contamination can lead to erroneous readings. Most fixtures are designed to accommodate a variety of conductor shapes and sizes, and many incorporate advanced features such as automated measurement systems and graphical user interfaces, making the testing process more efficient and user-friendly.

conductor resistance fixture

The methodology used in these fixtures often follows standardized testing procedures, such as those set by ASTM or IEC. These standards provide a framework that ensures consistency in measurements, allowing for accurate comparisons across different materials and conditions. By adhering to these norms, manufacturers and engineers can significantly improve the reliability of their products and systems.

Applications of conductor resistance fixtures can be found across multiple industries, including energy, telecommunications, and automotive sectors. In power generation and distribution, for example, ensuring that conductor resistances fall within acceptable limits is vital for minimizing energy losses and ensuring the longevity of equipment. In telecommunications, the fixture is used to assess the integrity of cables, ensuring that signals can be transmitted with minimal attenuation.

Furthermore, as industries strive towards greater sustainability, conductor resistance measurement becomes increasingly important. With the rise of renewable energy systems such as solar panels and wind turbines, the efficiency of electrical components has a direct impact on the overall performance of these systems. Regular testing with conductor resistance fixtures helps to optimize the performance of these technologies and is essential for maintaining compliance with regulatory standards.

In conclusion, conductor resistance fixtures play an indispensable role in the field of electrical engineering. By providing accurate measurements of resistance, these fixtures help to ensure the efficiency, safety, and reliability of electrical systems across various applications. As technology continues to evolve, the importance of these fixtures will only grow, driving innovations in design and functionality to meet the needs of a rapidly changing world.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy