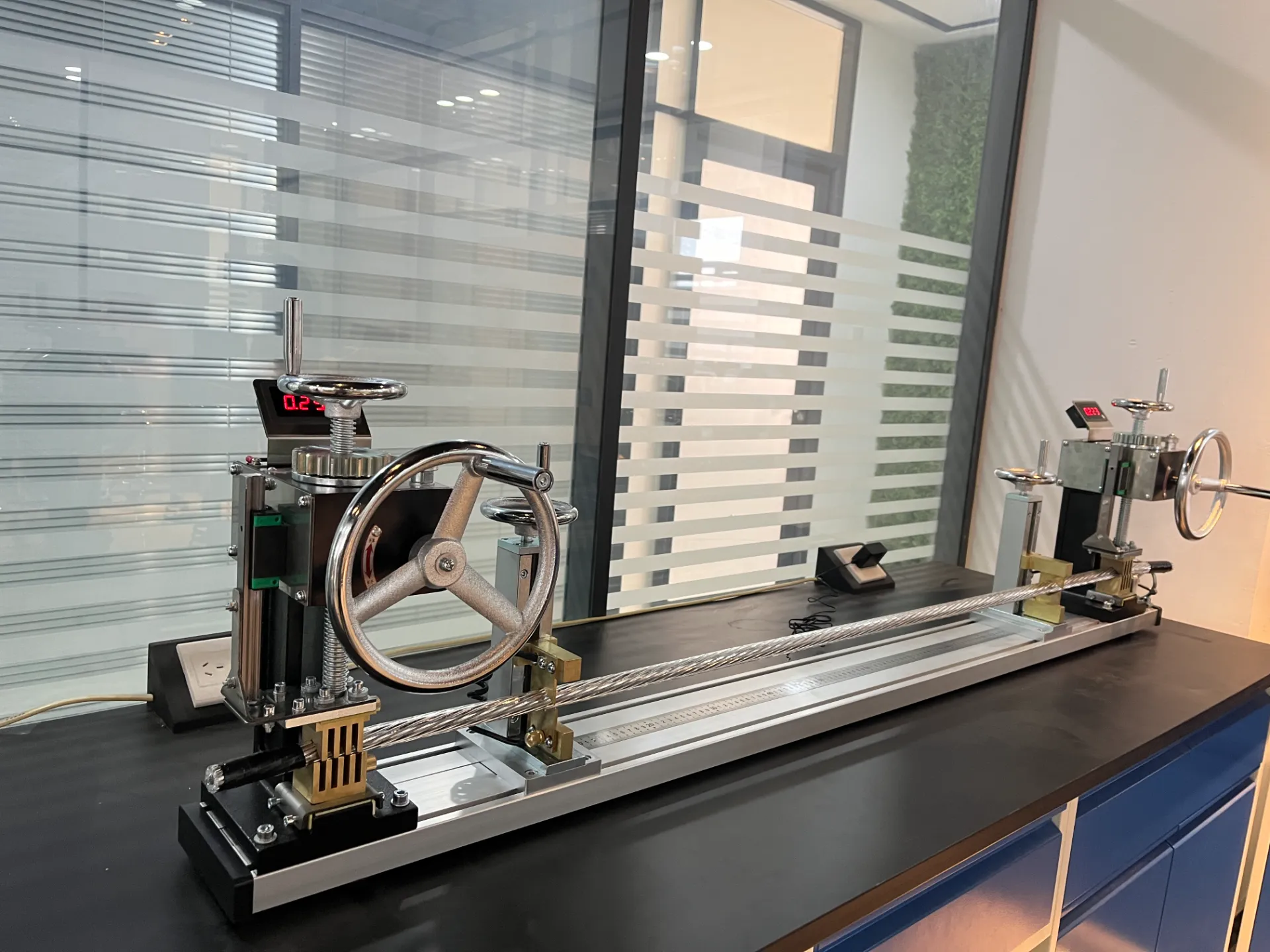

Factory for Measuring Conductor Resistance with Specialized Equipment

Conductor Resistance Measurement Equipment Ensuring Electrical Integrity

In the realm of electrical engineering, the importance of accurately measuring the resistance of conductors cannot be overstated. The efficiency and safety of electrical systems hinge on the integrity of their conductors. This makes conductor resistance measurement equipment an essential component in various industrial applications. Factories that specialize in the production of this equipment play a critical role in ensuring that electrical systems operate reliably and safely.

Understanding Conductor Resistance

Conductor resistance refers to the opposition to the flow of electric current through a conductor. It is influenced by several factors, including the material of the conductor, its length, cross-sectional area, and temperature. For instance, copper, with its excellent conductivity, has a lower resistance compared to other materials like aluminum. Accurately measuring this resistance is crucial because high resistance can lead to power losses, overheating, and even catastrophic failures in an electrical system.

The Importance of Measurement Equipment

Specialized equipment is employed to measure conductor resistance, ensuring compliance with industry standards and safety regulations. There are several types of devices used, including four-wire-ohm meters, which provide a highly accurate measurement by eliminating the effects of lead and contact resistances. Other devices like micro-ohmmeters are specifically designed for low-resistance measurements, making them ideal for applications where high precision is necessary.

Key Features of Quality Equipment

When selecting measurement equipment, several key features should be considered

1. Accuracy and Precision High-quality instruments offer accuracy within tight tolerances, ensuring that the measurements are reliable. 2. Temperature Compensation As resistance can change with temperature, effective measurement equipment often includes features to compensate for temperature variations. 3. User-friendly Interfaces Modern devices often come with intuitive displays and interfaces, simplifying operation for technicians who may not have specialized training. 4. Portability In many industrial environments, portability is essential. Compact and lightweight devices allow for measurements to be taken on-site without compromising functionality.

conductor resistance measurement equipment factory

Applications in Various Industries

Conductor resistance measurement equipment finds applications across numerous industries. In the power generation sector, for instance, ensuring the integrity of electrical connections is vital for preventing outages and maintaining system stability. In transportation, it is equally critical for rail systems and electric vehicles to have low-resistance pathways for efficient operation. Manufacturing facilities must also monitor conductor resistance to avoid failures that can lead to costly downtimes or accidents.

Quality Assurance in Manufacturing

Factories that produce conductor resistance measurement equipment follow stringent quality assurance protocols to ensure their products meet rigorous standards. This includes thorough testing during the design phase, stringent quality control during assembly, and regular calibration to maintain accuracy over time. Compliance with international standards, such as ISO and IEC, is essential in gaining trust from customers around the world.

The Future of Measurement Equipment

The future of conductor resistance measurement equipment looks promising with advancements in technology. The integration of IoT technology allows for real-time monitoring and data collection, which can significantly enhance predictive maintenance capabilities. Furthermore, developments in materials science may lead to the production of even more efficient conductors, thereby changing the benchmarks for resistance measurements.

Conclusion

In conclusion, conductor resistance measurement equipment is indispensable in maintaining the integrity of electrical systems across various sectors. Factories that specialize in the production of this equipment are not only critical for ensuring operational efficiency but also for enhancing safety and reliability. As technology continues to evolve, these devices will become even more sophisticated, further underscoring the importance of accurate resistance measurement in our increasingly electrified world. Investing in high-quality measurement tools is not merely a technical choice; it is a commitment to safety, performance, and innovation in electrical engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy