conductor resistance measurement machine manufacturer

Understanding Conductors The Role of Resistance Measurement Machines

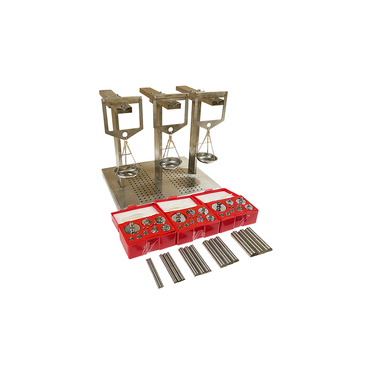

In the world of electrical engineering, the significance of conductor resistance cannot be overstated. Conductors are materials that allow electricity to flow through them with minimal resistance, and their efficiency can profoundly affect the performance of electrical systems. To ensure that conductors meet the required standards, manufacturers rely on specialized equipment known as resistance measurement machines. In this article, we will explore the importance of these machines, their capabilities, and what to look for when selecting a manufacturer.

The Importance of Measuring Conductor Resistance

Every electrical conductor has a specific resistance, which is influenced by several factors, including the material composition, temperature, and the physical condition of the conductor. High resistance can lead to energy losses in the form of heat, resulting in decreased efficiency and potentially hazardous conditions. As such, accurately measuring the resistance of conductors is crucial for various applications, including power transmission, telecommunications, and electronics.

Resistance measurement machines are instrumental in this process, providing precise measurements that help engineers and manufacturers maintain quality control. By identifying any issues with conductor resistance early in the manufacturing process, companies can troubleshoot problems before they escalate, ensuring their products meet safety and performance standards.

Key Features of Resistance Measurement Machines

Resistance measurement machines come equipped with an array of features designed to enhance measurement accuracy and efficiency. Some of the key features to consider include

1. Measurement Range and Accuracy The best machines provide a wide measurement range with high accuracy levels. This capability allows manufacturers to test a variety of conductors, from small wires to large cables, without compromising precision.

2. User-Friendly Interface An intuitive and user-friendly interface is essential for efficient operation. Advanced machines often feature touch screens, customizable settings, and easy navigation to enhance user experience.

3. Data Logging and Analysis Modern resistance measurement machines often come equipped with data logging capabilities. This feature allows users to record measurements over time, analyze trends, and generate reports for quality assurance purposes.

conductor resistance measurement machine manufacturer

4. Portability For manufacturers who conduct field testing, portability is a significant advantage. Compact and lightweight resistance measurement machines enable technicians to perform tests on-site, saving time and resources.

5. Safety Features High-quality machines incorporate safety features to protect both the operator and the equipment. These may include overload protection and automatic shut-off mechanisms.

Choosing the Right Manufacturer

When selecting a manufacturer for resistance measurement machines, several factors should be taken into consideration

- Reputation and Experience Look for manufacturers with a proven track record in producing reliable and accurate measurement equipment. Reading customer reviews and seeking recommendations can provide valuable insights.

- Support and Service Consider the level of customer support offered by the manufacturer. A responsive support team can be invaluable, especially when troubleshooting issues or during maintenance.

- Customization Options Every business has unique needs. Manufacturers that offer customization options can provide machines tailored to specific requirements, enhancing overall efficiency.

- Warranty and Maintenance A solid warranty and maintenance plan indicate the manufacturer’s confidence in their product. It's important to understand the terms of service before making a purchase.

Conclusion

Resistance measurement machines play a pivotal role in ensuring the quality and performance of electrical conductors. For manufacturers, investing in high-quality measurement equipment is essential for maintaining standards and enhancing operational efficiency. By carefully choosing the right machine and manufacturer, businesses can ensure accurate measurements, leading to safer and more efficient electrical systems. As technology continues to advance, staying informed about the latest developments in resistance measurement will further empower manufacturers to achieve excellence in their products.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy