Top Companies Offering Conductor Resistance Testing Equipment for Electrical Applications

Understanding the Importance of Conductor Resistance Test Equipment in the Electrical Industry

In the realm of electrical engineering, the importance of high-quality conductors cannot be overstated. Conductors are essential for the transmission of electrical power, and their resistance characteristics play a critical role in determining the efficiency and reliability of electrical systems. To ensure the proper functioning of conductors, specific tests must be carried out, among which conductor resistance tests are paramount. These tests measure the resistance of conductors, helping in identifying problems such as corrosion, loose connections, or other anomalies that may affect performance. This article provides insights into the significance of conductor resistance testing and highlights key players in the field.

Conductor resistance testing is crucial for maintaining electrical systems. High resistance in a conductor can lead to overheating, energy loss, and even catastrophic failures. The phenomenon of resistance is influenced by several factors, including the material composition, temperature, length, and cross-sectional area of the conductor. Therefore, regular testing is necessary to ensure that conductors operate within acceptable resistance limits. This not only guarantees system reliability but also compliance with safety standards.

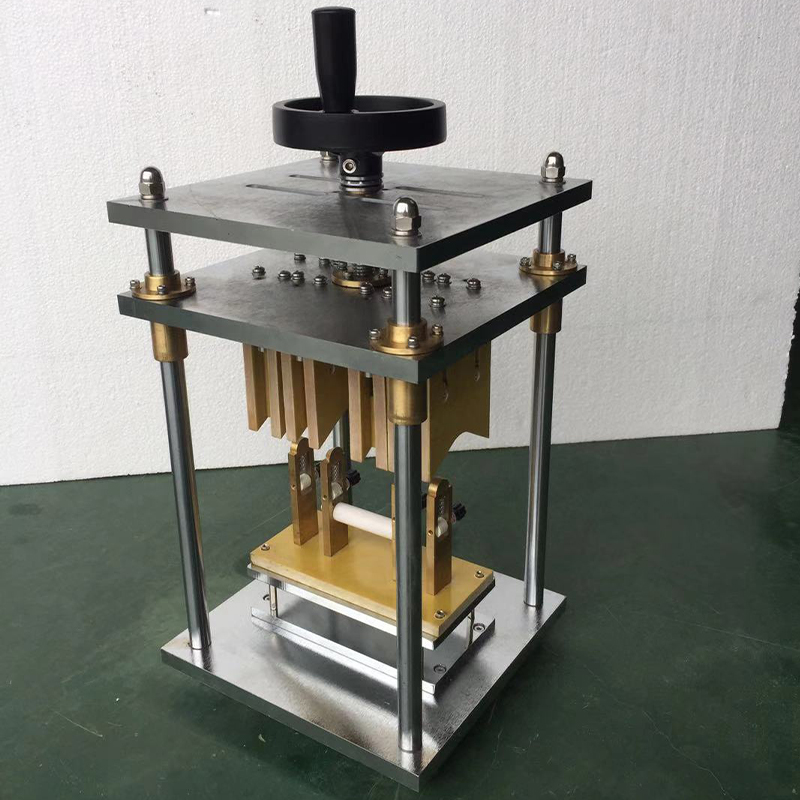

To carry out these tests effectively, specialized equipment is required. Several companies have established themselves as leaders in manufacturing and supplying conductor resistance test equipment. These companies provide a range of products designed to facilitate accurate and efficient resistance measurements.

One prominent company in this field is Megger, renowned for its innovative electrical testing equipment. Megger's range includes digital low-resistance ohmmeters and other testing devices specifically engineered for conductor resistance testing. Their products are known for their precision and ease of use, making them a preferred choice for electrical professionals. Additionally, they offer comprehensive support and training to help users maximize the effectiveness of their equipment.

conductor resistance test equipment companies

Another key player is Fluke Corporation, which produces a variety of testing and troubleshooting equipment, including resistance test devices designed for electrical applications. Fluke's test equipment is celebrated for its durability and reliability. Their user-friendly interfaces ensure that technicians can quickly and accurately assess conductor resistance, allowing for timely maintenance and repairs.

AEMC Instruments is also a significant contributor to the conductor resistance testing sector. They offer a variety of testing solutions, including portable and handheld ohmmeters designed for high-precision measurements. AEMC's equipment is particularly valued for its ability to carry out tests in challenging field conditions while still delivering accurate results.

In addition to these companies, there are numerous specialized firms dedicated to manufacturing conductor resistance test equipment. Each company typically provides a range of products that cater to different segments of the market, including utility companies, industrial enterprises, and contractors. As the demand for reliable electrical systems continues to grow, so does the need for high-quality testing equipment.

In conclusion, conductor resistance testing is an integral aspect of electrical system maintenance. The ability to measure and monitor the resistance of conductors can significantly enhance the safety and efficiency of electrical installations. Companies such as Megger, Fluke Corporation, and AEMC Instruments are at the forefront of developing advanced testing solutions that enable engineers and technicians to conduct these vital tests effectively. As technology continues to evolve, the importance of reliable conductor resistance test equipment will only increase, echoing the essential role that these devices play in safeguarding our electrical infrastructure.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy