conductor resistance test fixture companies

Understanding Conductor Resistance Test Fixture Companies

In today’s highly interconnected world, the importance of electrical components cannot be overstated. A critical aspect of electrical engineering and manufacturing involves ensuring the reliability and efficiency of conductors used in various applications. One of the key tools in this assessment is the conductor resistance test fixture, which plays a vital role in measuring the resistance of electrical conductors. This measurement is essential for ensuring compliance with industry standards, optimizing performance, and preventing potential failures.

What are Conductor Resistance Test Fixtures?

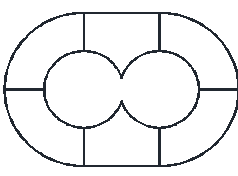

Conductor resistance test fixtures are specialized devices used to accurately measure the electrical resistance of a conductor. This process involves passing a known current through the conductor and measuring the resulting voltage drop. Ohm's Law is then used to calculate resistance. Such testing is crucial for quality control in manufacturing processes, ensuring that components meet specifications for electrical performance and safety.

These test fixtures can vary in complexity from simple handheld devices to sophisticated automated systems that provide extensive reporting capabilities. The choice of fixture often depends on the specific application and the level of precision required.

Companies Specializing in Conductor Resistance Test Fixtures

The demand for reliable conductor resistance test fixtures has led to the proliferation of companies specializing in their design and manufacture. These companies often implement advanced technologies to enhance measurement accuracy and efficiency. Here’s a look at some prominent features and offerings from these manufacturers

1. Innovation and Technology Industry-leading companies invest heavily in research and development to offer state-of-the-art test fixtures that incorporate the latest technologies. Features may include automated calibration processes, user-friendly interfaces, and data logging capabilities which help maintain accuracy and streamline testing.

conductor resistance test fixture companies

2. Customization Different sectors require distinct testing parameters. Top manufacturers often offer customizable solutions tailored to specific customer needs, ranging from modifications to existing models to fully bespoke fixtures designed from the ground up. This adaptability makes it possible for companies to meet compliance standards across a variety of industries such as telecommunications, aerospace, and automotive.

3. Quality Assurance Renowned companies often adhere to international standards for quality assurance, such as ISO certifications. They implement rigorous testing protocols to ensure that their products are both reliable and durable, capable of withstanding the demands of heavy industrial use.

4. Support and Maintenance Effective customer support is another hallmark of reputable test fixture companies. This support may include training for personnel in the proper use of testing equipment, as well as ongoing maintenance services to ensure the longevity and operational efficiency of the fixtures.

5. Cost Efficiency With advancements in technology, manufacturers are also focusing on cost-effective solutions that do not compromise on quality. This has opened the door for small to medium-sized enterprises to access high-quality testing equipment without the associated high costs.

Conclusion

The role of conductor resistance test fixture companies is central to ensuring the reliability and efficiency of electrical conductors across various applications. As industries evolve and the demand for electrical safety and performance increases, these companies are well-positioned to provide innovative, customized, and efficient testing solutions.

Investing in high-quality conductor resistance test fixtures is essential for manufacturers aiming to uphold standards and minimize risks associated with electrical failures. With the right tools and partnerships, companies can successfully navigate the complexities of modern electrical engineering, ensuring that their products not only meet but exceed safety and performance expectations. Whether for large manufacturers or specialized firms, choosing the right test fixture provider is paramount to achieving excellence and reliability in conductor performance.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy