conductor resistance test fixture factories

The Importance of Conductor Resistance Test Fixture in Electrical Engineering

In the field of electrical engineering, the reliability and efficiency of electrical systems rely heavily on the integrity of their components. One critical aspect of this integrity is the resistance of conductors, which can impact performance and safety. To evaluate this parameter accurately, conductor resistance test fixtures play a vital role. This article will delve into what conductor resistance test fixtures are, their significance, and the manufacturing aspects involved in their production.

Understanding Conductor Resistance

Conductor resistance refers to the opposition that a material presents to the flow of electric current. A lower resistance in conductors ensures that electrical systems run efficiently, minimizing energy loss and preventing overheating. It is essential to test resistance in various components, including wires, cables, and circuit boards, to ensure they are functioning within acceptable limits.

What is a Conductor Resistance Test Fixture?

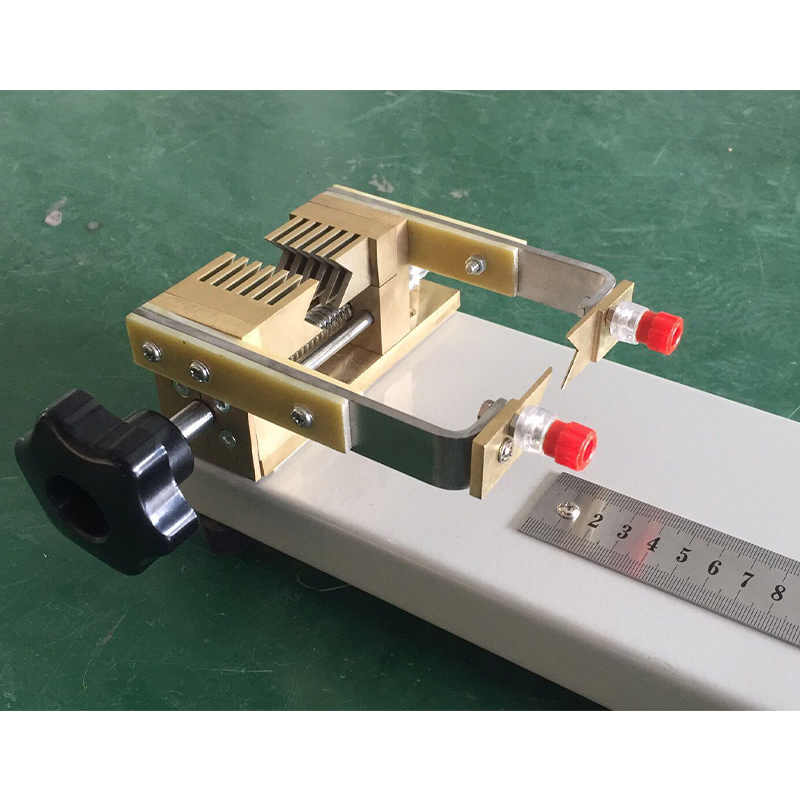

A conductor resistance test fixture is a specialized equipment designed to measure the resistance of conductive materials under controlled conditions. These fixtures typically consist of terminals for connection, a precise measuring instrument, and a robust structure that holds the components in place during testing. The most common method to evaluate resistance is the four-wire measurement technique, which eliminates the influence of lead resistance on the measurement, providing accurate readings.

Importance in Electrical Engineering

1. Quality Assurance In manufacturing, ensuring that conductors meet specified resistance standards is crucial for the quality and reliability of end products. Regular testing using fixtures can help manufacturers maintain high-quality control.

2. Safety Compliance Electrical systems are subject to rigorous safety standards mandated by regulatory bodies. By testing conductors with dedicated fixtures, manufacturers can ensure compliance with these regulations, reducing the risk of failures that could lead to hazardous situations or legal liabilities.

3. Performance Optimization Conductors with high resistance can lead to energy losses and inefficiencies in electrical systems. By testing and identifying high-resistance components, engineers can make modifications to improve overall system performance.

4. Research and Development In the R&D phase, testing fixtures allow for experimentation with different conductor materials and designs. Understanding how resistance varies with different configurations can lead to innovations in material science and electrical engineering.

conductor resistance test fixture factories

The Manufacturing Process of Test Fixtures

The production of conductor resistance test fixtures involves several critical steps

1. Design The design phase is fundamental. Engineers need to consider the specifications required for the fixtures, including size, material compatibility, and the expected range of resistance measurements.

2. Material Selection High-quality materials that can withstand repeated use and provide accurate readings are essential. Common materials include robust plastics and metal alloys that minimize resistance and environmental impact.

3. Fabrication Advanced manufacturing techniques such as CNC machining and 3D printing may be employed to create precise components that meet the designed specifications.

4. Calibration After manufacturing, the fixtures need to be calibrated against standard resistance measurements. This calibration ensures that the fixtures provide reliable results when testing conductors.

5. Testing and Quality Control Final testing is conducted to ensure that each fixture meets quality standards. This step is critical before the fixtures are dispatched to customers.

Future Directions

As technology evolves, the demand for more advanced conductor resistance test fixtures is likely to increase. Innovations such as integrated digital measurement systems, enhanced automation, and connectivity features may reshape how tests are conducted and data is recorded. Furthermore, the growing emphasis on energy efficiency and the integration of renewable energy systems will drive the need for reliable testing solutions.

Conclusion

Conductor resistance test fixtures are indispensable tools in electrical engineering that ensure the quality, safety, and performance of electrical components. With a robust manufacturing process and a focus on innovation, these fixtures will continue to play a crucial role in advancing electrical systems and supporting the industry’s growth. Understanding their significance not only highlights their necessity but also advocates for continuous development in testing methodologies to enhance the reliability of electrical systems globally.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy