conductor resistance test fixture factory

Understanding Conductor Resistance Test Fixture Factories

In the realm of electrical engineering, the importance of accurately measuring the resistance of conductors cannot be overstated. Conductor resistance testing is vital in ensuring that electrical components and systems function safely and efficiently. To facilitate these tests, specialized equipment known as conductor resistance test fixtures is manufactured in dedicated factories. This article delves into the role of these factories, the technology involved in producing test fixtures, and their significance in the electrical industry.

What is a Conductor Resistance Test Fixture?

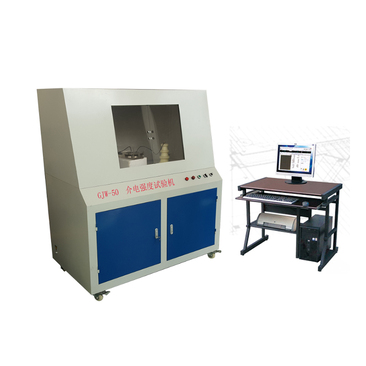

A conductor resistance test fixture is an essential tool used to measure the resistance of electrical conductors, such as wires and cables. The fixture is designed to provide a stable and uniform testing environment while ensuring accuracy and repeatability in results. Typically, it comprises various components, including terminals for connection, a measurement device, and a fixture body that holds the conductor in place during testing.

These fixtures are engineered to accommodate a wide range of conductor sizes and types, making them versatile tools for manufacturers, laboratories, and quality assurance departments. The resistance is usually measured using methods such as the four-wire or Kelvin method, which minimizes errors caused by contact resistance and lead resistance.

The Manufacturing Process

Conductor resistance test fixture factories employ advanced manufacturing techniques to produce high-quality testing equipment. The process begins with the design phase, where engineers leverage computer-aided design (CAD) software to create precise specifications for the fixtures. This stage is critical, as the design must ensure that the fixture can accommodate various conductor sizes while maintaining the integrity of measurements.

conductor resistance test fixture factory

Once the designs are finalized, the manufacturing process involves several steps. Precision machining is used to fabricate components from materials like aluminum or stainless steel, which provide durability and conductivity. Automated assembly lines often aid in streamlining production, ensuring that fixtures are constructed efficiently and to strict quality standards.

Quality control plays a pivotal role in the manufacturing process. Factories conduct thorough testing of both the materials and the finished products to guarantee that they meet industry standards and regulations. This step is crucial, as the functional reliability of the test fixtures directly impacts the results obtained during conductor resistance testing.

Importance in the Electrical Industry

Conductor resistance test fixtures are indispensable in various sectors of the electrical industry. Their primary application lies in manufacturing, where they ensure that products such as cables and connectors meet electrical specifications before reaching the market. Additionally, these fixtures are widely used in research and development settings, where accurate measurements are critical for testing prototypes and new technologies.

Furthermore, regular testing of existing electrical infrastructure is vital for maintenance and safety. In industries like aerospace, automotive, and power generation, any failure in electrical conductivity can lead to significant hazards. Therefore, having reliable test fixtures is essential for ensuring compliance with safety regulations and maintaining optimal performance.

Conclusion

Conductor resistance test fixture factories play a crucial role in the electrical manufacturing landscape. By providing the necessary tools for accurate resistance measurement, these factories contribute significantly to the quality and safety of electrical components. The intersection of advanced manufacturing processes and essential engineering principles ensures that these fixtures remain reliable, efficient, and pivotal in maintaining the integrity of electrical systems across various industries. As technology continues to evolve, so too will the designs and functionalities of conductor resistance test fixtures, further enhancing their role in the ever-growing electrical industry.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy