Resistance Testing Equipment for Conductors from Leading Manufacturers in the Industry

Understanding Conductor Resistance Test Machines A Gateway to Quality Assurance

In the world of electrical engineering, the reliability and efficiency of electrical systems are paramount. One critical aspect of this reliability is the resistance of conductors used in these systems. Over time, the performance of conductors can degrade due to factors such as corrosion, mechanical damage, and thermal stress. To address these issues, conductor resistance test machines have become an essential tool in assessing the quality and performance of electrical conductors.

The Importance of Conductor Resistance Testing

Before delving into the specifics of conductor resistance test machines, it is vital to understand why resistance testing is crucial. Conductors, whether in the form of wires, cables, or busbars, are expected to carry electrical current efficiently. Any increase in resistance can lead to various problems, including overheating, energy loss, and diminished performance of electrical circuits. By regularly testing the resistance of conductors, engineers can identify potential issues early, allowing for timely maintenance or replacement, thereby ensuring the longevity and reliability of electrical systems.

Features of Conductor Resistance Test Machines

Conductor resistance test machines are designed to provide accurate and reliable measurements of the resistance in electrical conductors. These machines typically incorporate the following features

1. High Precision Measurements Quality test machines provide precise measurements of resistance, often down to micro-ohms. This level of accuracy is essential for ensuring that conductors meet regulatory and safety standards.

2. User-Friendly Interface Modern machines are equipped with intuitive interfaces, allowing operators to easily set up tests, operate the machine, and interpret results. Many include digital displays that provide real-time readings and results.

conductor resistance test machine factory

3. Automated Testing Advanced models can automate the testing process, significantly reducing the time and effort required for testing large batches of conductors. Automation minimizes human error, ensuring consistent and reliable results.

4. Data Logging and Analysis Many conductor resistance test machines come with the ability to log test results. This feature enables engineers to track resistance over time, analyze trends, and maintain records of testing for auditing purposes.

5. Multi-Functionality Some machines are designed not just for resistance testing but also for other parameters like voltage and current testing, thus enhancing their utility in the field.

Selecting the Right Test Machine

When choosing a conductor resistance test machine, several factors should be considered

- Application Identify the specific needs based on the type of conductors and the environment in which they will be used. Machines designed for industrial applications may differ from those intended for small-scale use. - Capacity Ensure that the machine can handle the maximum resistance levels expected in your application. - Calibration and Standards Compliance Select a machine from a reputable manufacturer that provides machines compliant with international testing standards such as IEC or ASTM. - Support and Service Consider the availability of technical support and whether the manufacturer offers calibration and maintenance services.

Conclusion

In conclusion, conductor resistance test machines are invaluable tools in the maintenance of electrical systems and infrastructure. Their ability to provide accurate and timely measurements ensures that conductors function optimally and safely. By investing in quality conductor resistance testing equipment, engineers and technicians can significantly enhance the reliability of electrical systems, ultimately leading to safer and more efficient operation. As technology continues to advance, the design and functionalities of these machines will undoubtedly continue to improve, aiding industries in maintaining their electrical systems with even greater precision and efficiency.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

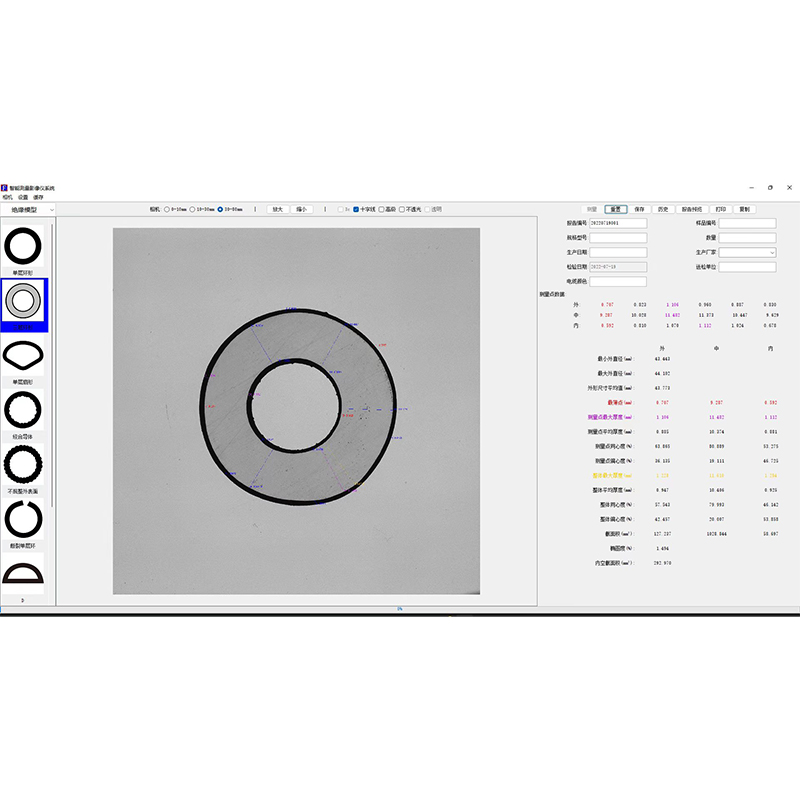

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy