Supplier of Conductor Resistance Test Equipment for Electrical Testing Applications

Understanding the Importance of Conductor Resistance Test Machines

In the realm of electrical engineering, ensuring the reliability and efficiency of power systems is paramount. A critical component in achieving this reliability is the conductor used in various applications, ranging from transmission lines to power generation facilities. One essential test to guarantee the quality of these conductors is the conductor resistance test. This is where conductor resistance test machines come into play, serving as indispensable tools in assessing the viability and performance of electrical conductors. As the demand for high-quality power systems continues to rise, finding a reputable supplier of conductor resistance test machines becomes increasingly important.

What is Conductor Resistance Testing?

Conductor resistance testing measures the resistance of electrical conductors, typically during production or maintenance phases. The resistance of a conductor can indicate its quality, affecting its performance in terms of efficiency and safety. When the resistance exceeds specified limits, it can lead to overheating, power losses, and, in severe cases, failure of the electrical system. Therefore, understanding the resistance characteristics of a conductor is vital for engineers and operators.

The testing process involves passing a known current through the conductor and measuring the resulting voltage drop, using Ohm’s law (V = IR) to calculate the resistance. Accurate results are crucial, and this is where the quality and reliability of the test equipment come into play.

The Role of Conductor Resistance Test Machines

Conductor resistance test machines are designed to provide precise measurements of conductor resistance. They are equipped with advanced technologies and features tailored to meet diverse testing requirements. These machines can vary significantly in terms of design, measurement range, and functionalities. Key features often include

1. High Accuracy and Sensitivity Quality test machines offer high precision in measurements, which is essential for reliable results. 2. User-friendly Interfaces Modern devices come with intuitive interfaces, making them easy to operate and interpret results.

3. Automatic Calibration Advanced models include automated calibration features that ensure consistent and accurate readings over time.

4. Portability Some machines are designed to be portable, allowing engineers to conduct tests on-site, which is invaluable for maintenance and troubleshooting.

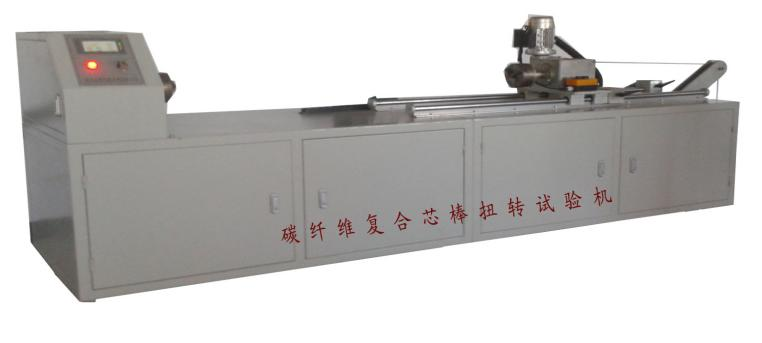

conductor resistance test machine supplier

Choosing the Right Supplier

When selecting a conductor resistance test machine, the supplier's reputation and product quality are imperative. A reliable supplier should offer

- Expertise in Electrical Testing Suppliers with a solid background in electrical engineering are more likely to provide machines that meet industry standards.

- Comprehensive Customer Support Quality technical support and after-sales service can significantly enhance the user experience and extend the lifespan of the equipment.

- Customization Options Different industries may require specific features or modifications. Suppliers willing to customize machines to meet particular needs are often preferable.

- Competitive Pricing While quality should never be compromised, the cost is an important factor. Compare prices from multiple suppliers to ensure competitive rates.

- Warranty and Service Plans A solid warranty and service agreement can protect your investment and provide peace of mind.

Conclusion

In conclusion, conductor resistance testing is a critical component in maintaining the reliability and efficiency of electrical systems. The need for high-quality conductor resistance test machines cannot be overstated, as they ensure accurate measurements that can significantly influence performance outcomes. Selecting a reputable supplier is crucial to obtaining reliable testing equipment that meets the specific needs of the industry. As technology evolves, the offerings in this space are likely to expand, providing even greater capabilities and efficiencies. Ultimately, investing in quality testing equipment will lead to more efficient, safer, and reliable electrical systems, which benefit not only individual businesses but also the larger grid infrastructure and society as a whole.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy