conductor resistance test machine supplier

Understanding the Importance of Conductor Resistance Test Machines A Guide for Suppliers

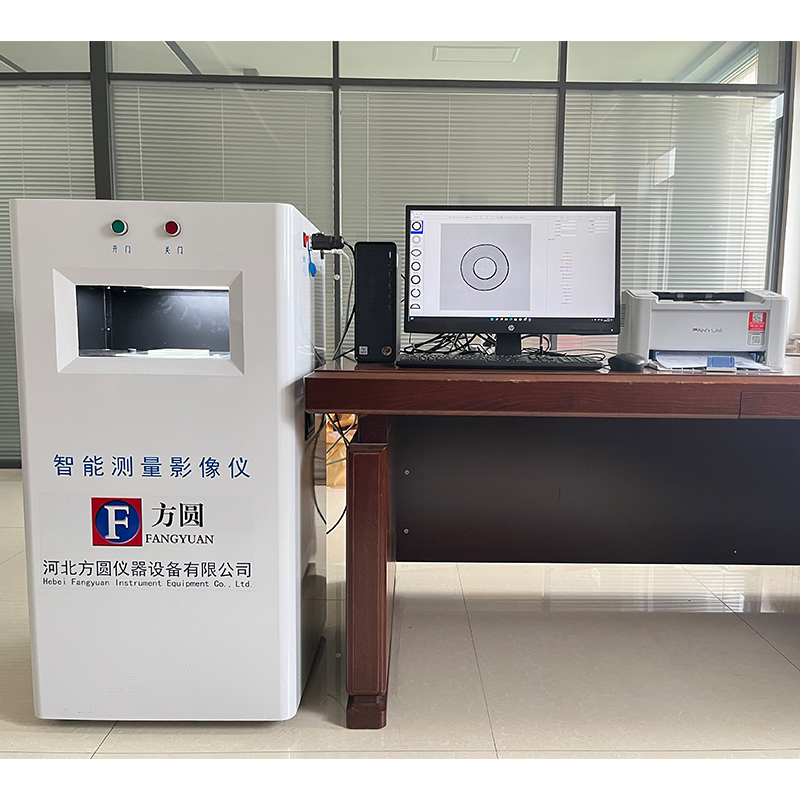

In the realm of electrical engineering and cable testing, the significance of conductor resistance test machines cannot be overstated. These machines play a pivotal role in ensuring the performance and safety of electrical components, particularly in high-voltage applications. As the demand for reliable and efficient electrical systems continues to rise, suppliers of conductor resistance test machines are increasingly essential to the industry.

What is a Conductor Resistance Test Machine?

A conductor resistance test machine is designed to measure the electrical resistance of conductive materials, especially electric cables. This is crucial for assessing the quality of the conductor and ensuring that it meets the necessary specifications and standards. The resistance measurement helps in identifying any defects or corrosion that may affect the performance of the conductor over time.

Typically, the test is carried out using a four-terminal (Kelvin) method, which helps eliminate the influence of lead and contact resistance, providing accurate readings. Suppliers that specialize in these machines offer a range of models, from portable devices for field testing to sophisticated systems for laboratory use.

Key Features of Conductor Resistance Test Machines

1. Accuracy High precision in resistance measurement is critical. Suppliers focus on providing machines that can measure low resistance values with great accuracy, which is essential for high-performance applications.

2. Ease of Use Modern conductor resistance test machines are often equipped with user-friendly interfaces. Features such as touchscreens, automated testing sequences, and clear display readings make it easier for technicians to operate the equipment efficiently.

3. Durability and Portability Many suppliers offer portable options that are rugged and suitable for various testing environments. These machines are built to withstand tough conditions while maintaining accuracy in their readings.

4. Data Management With the rise of digital technology, many suppliers integrate data logging features in their machines. This allows users to store and analyze test results over time, facilitating better maintenance planning and compliance with industry standards.

conductor resistance test machine supplier

5. Safety Features Electrical testing can be hazardous. Reliable suppliers ensure that their machines come equipped with safety mechanisms, such as overcurrent protection, to safeguard both the operator and the equipment.

Choosing the Right Supplier

When selecting a supplier for conductor resistance test machines, several factors should be considered

- Reputation and Experience Look for suppliers with a proven track record in the industry. A company that specializes in electrical testing equipment will likely provide superior products and support.

- Customer Support A good supplier will offer comprehensive customer service, including training, technical support, and a robust warranty policy.

- Customization Options Different applications may require specific features. Reputable suppliers may offer customization options to suit unique testing needs.

Conclusion

As the electrical industry continues to evolve, the role of conductor resistance test machines will remain pivotal in maintaining system integrity and safety. Suppliers who prioritize quality, innovation, and customer service will be at the forefront of this essential market. By investing in high-quality testing equipment, organizations can ensure that their electrical systems operate efficiently and reliably, ultimately contributing to a safer and more efficient energy landscape.

In conclusion, choosing the right conductor resistance test machine and supplier is not just a matter of convenience; it is a critical investment in the reliability and safety of electrical systems.

-

Reliable CHJ Series Spark Tester for Insulation Quality Control

NewsSep.01,2025

-

QNJ-2/3 Cable Flexibility Test Machine: Precision & Durability

NewsAug.31,2025

-

DQ-F Superfine Wire Conductor Resistance Fixture: High-Precision Testing

NewsAug.30,2025

-

ZC36 High Insulation Resistance: Reliable & Safe Performance

NewsAug.29,2025

-

CX-100 Manual Hydraulic Core Punching Machine - Efficient & Reliable

NewsAug.28,2025

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy