copper and steel resistance tester

Copper and Steel Resistance Tester A Comprehensive Overview

In today's industrial and technological landscape, the importance of ensuring the quality and reliability of materials cannot be overstated. Among various materials used in construction and manufacturing, copper and steel are two of the most prevalent due to their excellent conductivity, strength, and versatility. However, the properties of these materials may vary due to several factors, including impurities, temperature variations, and production methods. As a result, testing the resistance of copper and steel is crucial to guarantee their effectiveness and safety in various applications.

What is a Resistance Tester?

A resistance tester is an instrument used to measure the electrical resistance of a material. In practical terms, it applies a specific voltage to a conductor and measures the current that flows through it. Through Ohm's Law (R = V/I), where R is resistance, V is voltage, and I is current, the tester can determine the conductivity of the material. Resistance testers can be used for various purposes, including quality control in manufacturing, assessing the performance of electrical components, and determining the suitability of materials for specific applications.

Significance of Testing Copper and Steel

Both copper and steel serve critical functions in many industries, including electrical, construction, automotive, and aerospace. Copper is renowned for its excellent electrical conductivity, corrosion resistance, and thermal properties, making it the preferred choice for wiring and electrical applications. Meanwhile, steel, known for its strength and durability, is widely used in structural applications, automotive parts, and machinery.

Testing the resistance of these materials is essential because even minor changes in their composition or structure can lead to significant performance issues. For instance, high resistance in copper can result in overheating in electrical applications, leading to failures or fires. Similarly, excessive resistance in steel can indicate corrosion or damage, potentially compromising structural integrity.

Types of Resistance Testers

There are various types of resistance testers designed for different applications

1. Digital Multimeters (DMMs) These versatile tools can measure voltage, current, and resistance. They are widely used due to their ease of use and portability.

2. Micro-ohmmeters Specifically designed for measuring very low resistance levels, micro-ohmmeters are essential in applications where high precision is crucial, such as power generation and electrical connections.

copper and steel resistance tester

4. Four-Wire Resistance Measurement This method is used to eliminate the impact of lead and contact resistance, providing highly accurate measurements. It is particularly beneficial in laboratory settings and research applications.

How to Conduct a Resistance Test

When performing a resistance test on copper or steel, the following steps are generally followed

1. Preparation Ensure that the surfaces of the materials being tested are clean and free of contaminants. This ensures accurate readings.

2. Connection Connect the resistance tester according to the manufacturer’s instructions. If using a four-wire setup, make sure the current leads and voltage leads are correctly placed.

3. Testing Activate the tester and record the resistance values displayed. Take note of multiple readings if necessary, to ensure consistency.

4. Analysis Compare the measured resistance values with the material specifications. If the resistance exceeds acceptable limits, further investigation may be needed.

Conclusion

The resistance tester is an invaluable tool in ensuring the quality and reliability of both copper and steel materials. By accurately measuring the resistance of these conductors, industries can prevent costly failures, enhance safety, and maintain compliance with stringent regulations. The ongoing advancement of resistance testing technology continues to improve the precision and efficiency of these measurements, thereby aligning with the ever-evolving demands of modern industries. As such, regular testing of copper and steel not only contributes to operational efficiency but also plays a critical role in safeguarding lives and resources across various sectors.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

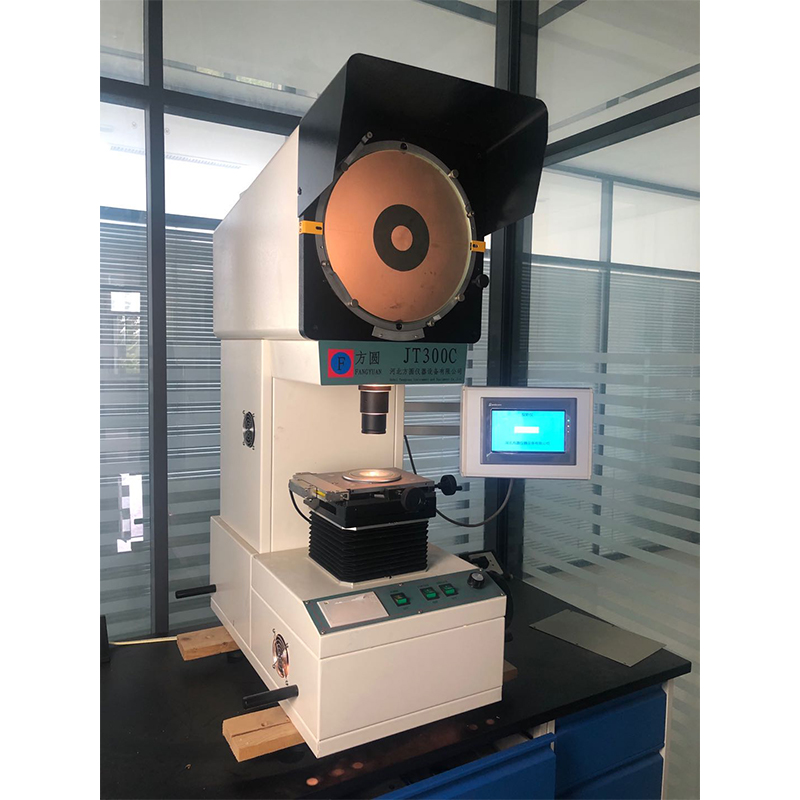

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy