cross-linked cable slicer company

Understanding Cross-Linked Cable Slicers Innovations and Applications

In today's fast-paced technological landscape, the demand for efficient and reliable manufacturing tools is paramount. One such tool that has garnered attention is the cross-linked cable slicer. This innovative device is especially crucial in industries where precision and durability are key, such as telecommunications, power distribution, and manufacturing. Understanding the significance of cross-linked cable slicers can illuminate their role in enhancing production efficiency and reducing labor costs.

What is a Cross-Linked Cable Slicer?

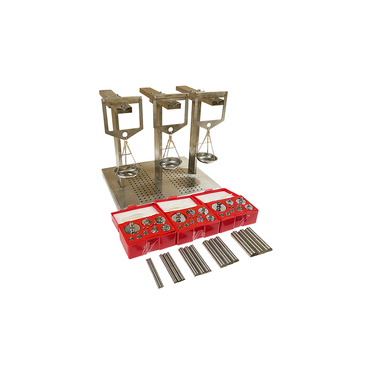

A cross-linked cable slicer is a specialized piece of equipment designed to accurately cut cables that have undergone a cross-linking process. Cross-linking is a chemical process that enhances the physical properties of materials, particularly thermoplastics, making them more heat-resistant, chemically stable, and mechanically robust. This process is widely used in the production of cables that must endure harsh environmental conditions, such as those found in outdoor installations or industrial applications.

The primary function of a cross-linked cable slicer is to deliver clean, precise cuts without damaging the integrity of the cable. Given that these cables are often composed of materials that are denser and more resilient than standard wiring, conventional cutting methods can lead to frayed edges, exposing the inner conductors and potentially compromising the cable's performance.

Advantages of Cross-Linked Cable Slicers

1. Precision Cutting The most notable advantage of using a cross-linked cable slicer is its ability to make precise cuts. This precision minimizes wastage and ensures that the cables can be easily terminated and connected.

2. Increased Efficiency Automated slicing mechanisms significantly reduce the time taken for manual cutting, thereby increasing overall production efficiency. With rapid cutting cycles, manufacturers can keep up with higher demand without sacrificing quality.

cross-linked cable slicer company

3. Improved Safety Many modern cross-linked cable slicers are designed with built-in safety features, reducing the risk of injury to operators. The automation of the cutting process means fewer manual interactions with sharp edges and moving parts.

4. Versatility These slicers are capable of handling a range of cable sizes and materials, making them a versatile addition to any manufacturing floor. Adaptable to various production needs, they can be programmed for different slicing patterns and dimensions.

5. Cost-Effectiveness By minimizing labor costs and reducing material wastage, cross-linked cable slicers can significantly enhance a company's bottom line. The initial investment in high-quality machinery is offset by the long-term savings in operational costs.

Applications in Various Industries

Cross-linked cable slicers see widespread use across multiple sectors. In telecommunications, for instance, they are essential in preparing cables for installation in networks that require high performance and reliability. In the power sector, they help in managing cables that must withstand extreme conditions, ensuring that energy distribution remains uninterrupted.

The automotive industry also benefits from these machines, as manufacturers use cross-linked cables in various applications, from power distribution to connectivity in electric vehicles. By leveraging cross-linked cable slicers, auto manufacturers can enhance both the quality and efficiency of their production lines.

Conclusion

In summary, cross-linked cable slicers represent a significant advancement in cable manufacturing technology. By offering precise cuts, enhanced safety, and increased efficiency, they play a crucial role in industries that demand high-quality results. As the manufacturing landscape continues to evolve with the advent of new materials and technologies, the importance of specialized equipment like cross-linked cable slicers will undoubtedly grow, paving the way for innovations that can meet the future’s demands. As such, investing in this technology is not just a matter of enhancing current capabilities but also a strategic move towards embracing the future of manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy