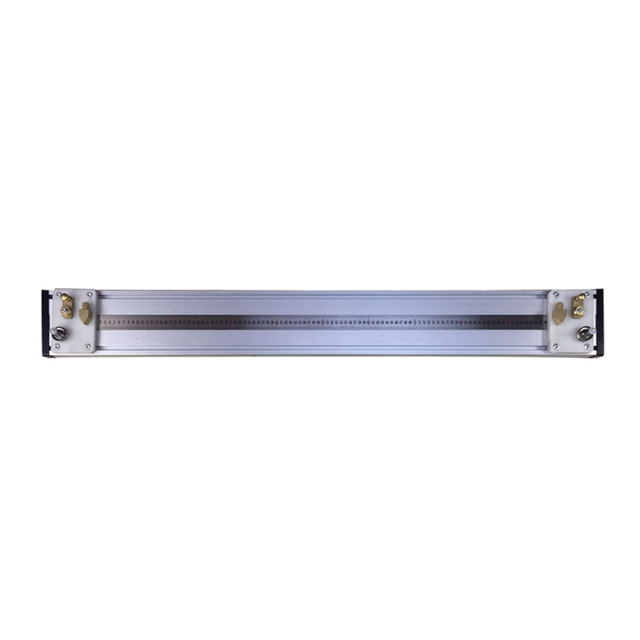

custom insulation resistance testers

Understanding Custom Insulation Resistance Testers

In today's increasingly electrified world, ensuring safety and reliability in electrical systems is paramount. One essential aspect of electrical maintenance is insulation resistance testing. This is where custom insulation resistance testers play a crucial role. These specialized devices are designed to measure the resistance offered by insulation materials, thereby assessing their effectiveness in preventing electrical leakage and maintaining safety standards.

What is Insulation Resistance Testing?

Insulation resistance testing involves assessing the resistance of an insulating material to electrical current. This is crucial for determining whether the insulation is intact and capable of preventing unwanted current flow. A low insulation resistance reading indicates potential hazards, such as electrical shock or fire, due to leakage currents. Typically, insulation resistance testers apply a high voltage (usually 250V, 500V, or 1000V) to the insulation and measure the resultant current, allowing for the calculation of resistance in megaohms (MΩ).

Why Custom Testers Are Important

While standard insulation resistance testers serve a broad purpose, custom insulation resistance testers are tailored to meet specific requirements of unique applications or environments

. Industries such as aerospace, automotive, manufacturing, and renewable energy often have distinct insulation testing needs. Therefore, custom testers can accommodate these demands by offering features like variable test voltages, enhanced data logging capabilities, and integration with other diagnostic tools.Features of Custom Insulation Resistance Testers

custom insulation resistance testers

1. Variable Voltage Settings Different insulation materials and applications require specific testing voltages. Custom testers can be designed to operate across a range of voltages, allowing users to tailor the test to the specific requirements of the equipment being tested.

2. Advanced Data Logging Custom testers often include enhanced data logging capabilities, enabling the collection of detailed test data over time. This can help in trend analysis and predictive maintenance, allowing operators to identify potential issues before they become serious problems.

3. User-Friendly Interfaces Many custom testers are designed with user-friendly interfaces that facilitate easy operation and straightforward interpretation of results. Features such as touchscreen displays, intuitive menus, and instant feedback improve efficiency and accuracy in testing.

4. Durability and Portability Certain industries may require testers that can withstand harsh conditions. Custom insulation resistance testers can be engineered to be both durable and portable, featuring rugged casings and lightweight designs for use in various environments.

5. Calibration and Certification Options To ensure accuracy, custom testers can be calibrated and certified to meet specific industry standards. This guarantees that the testing conducted is not only reliable but also compliant with regulatory requirements.

Conclusion

In conclusion, custom insulation resistance testers are an essential tool for ensuring the safety and reliability of electrical systems across various industries. By offering tailored solutions that meet specific testing needs, these devices contribute significantly to preventing electrical hazards and maintaining operational integrity. As technology continues to evolve, the importance of customized testing solutions will only grow, enhancing the overall efficiency and safety of electrical maintenance practices.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy