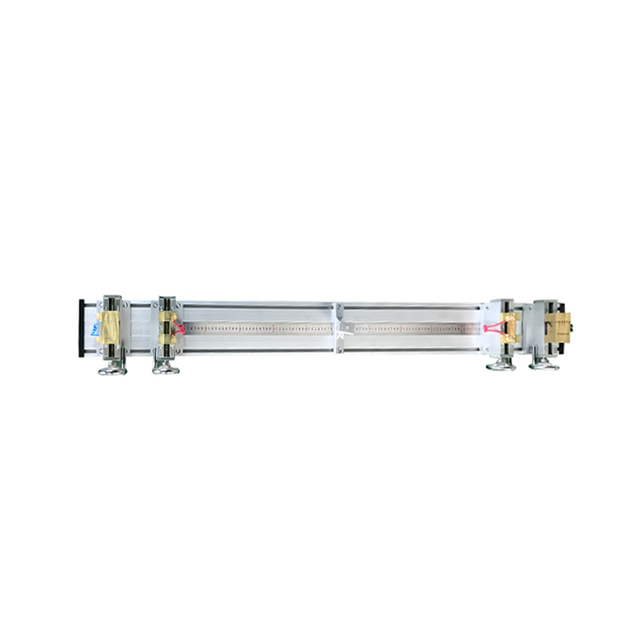

Custom Tensile Tester - ASTM D412 Compliance

Custom Tensile Tester ASTM D412 A Comprehensive Overview

Tensile testing is a fundamental method used in material science to assess the strength and ductility of materials. One of the established standards for tensile testing of elastomeric materials is ASTM D412, published by the American Society for Testing and Materials (ASTM). This standard specifies the equipment, procedures, and evaluation methods for determining the tensile properties of rubber and elastomeric compounds. The development of a custom tensile tester tailored to ASTM D412 provides significant advantages in both accuracy and adaptability, essential for modern material testing.

Custom Tensile Tester ASTM D412 A Comprehensive Overview

The custom design of a tensile tester can incorporate advanced features such as digital readouts, computer interfacing, and data logging capabilities. Digital readouts enhance the user experience by providing real-time feedback on the tensile properties being evaluated. Computer interfacing allows for automated control of the testing process and real-time data analysis, significantly improving efficiency. Furthermore, data logging is crucial for maintaining records of all tests conducted, essential for quality assurance and compliance with ISO standards.

custom tensile tester astm d412

Compatibility with a variety of test specimens is another critical aspect of customizing a tensile tester. ASTM D412 outlines specific specimen dimensions for different testing methods, such as Type A and Type B specimens. A custom tensile tester can be designed to accommodate various specimen sizes and shapes, thus enhancing its versatility across multiple testing scenarios. This adaptability is particularly beneficial for research laboratories and production environments that handle diverse materials and shapes.

In addition to hardware considerations, software integration plays a vital role in modern tensile testing. Utilizing sophisticated software enables users to analyze the data effectively, extracting meaningful insights from raw measurements. Statistical analysis tools can be integrated into the system to determine material properties such as ultimate tensile strength, yield strength, and elongation percentages, all of which are crucial for material performance evaluation.

Moreover, safety is a paramount concern in laboratory environments. Custom tensile testers can be equipped with safety features such as automated shut-off mechanisms, load limits, and protective enclosures to ensure operator safety while conducting tests. Implementing these safety measures not only protects personnel but also enhances the reliability of test results by minimizing disruptions during operation.

In conclusion, a custom tensile tester designed in accordance with ASTM D412 standards significantly enhances the testing of elastomeric materials. By integrating advanced technology, accommodating various specimen types, and implementing robust safety features, such testers provide reliable, accurate, and efficient methods for determining material properties. As industries increasingly rely on precise measurements for quality control and research purposes, investing in a well-designed custom tensile tester is essential for any laboratory or production facility focused on achieving excellence in material science. This not only ensures that materials meet performance specifications but also advances the overall knowledge within the field.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy