Custom AC Resistance Measurement Device for Accurate Testing Solutions

Understanding Custom AC Resistance Testers A Comprehensive Guide

In the world of electrical engineering and maintenance, ensuring the proper functionality of electrical systems is crucial. One of the key aspects of this maintenance involves measuring the resistance of various components, such as wires, circuits, and electrical equipment. This is where custom AC resistance testers come into play, offering tailored solutions to meet specific needs in measuring alternating current (AC) resistance.

What is an AC Resistance Tester?

An AC resistance tester is a specialized instrument designed to measure the resistance of electrical components under alternating current conditions. Unlike direct current (DC) resistance testers, AC resistance testers can provide more accurate readings for components operating in AC environments, where impedance can vary significantly due to factors such as frequency and inductance.

Why Customization Matters

The need for custom AC resistance testers stems from the diverse requirements of different industries and applications. Off-the-shelf testers may not always meet specific criteria, such as

1. Measurement Range Some applications require measurement in extreme ranges, either very low or very high resistance values, which necessitates a custom solution. 2. Frequency Response Different applications may operate at various frequencies. A customized tester can be designed to operate optimally at the required frequency, ensuring accurate readings.

3. Data Logging Features Many industries require detailed data recording for analysis and compliance with safety standards. Custom testers can be equipped with advanced data logging capabilities to meet these needs.

4. Enhanced Portability In many cases, particularly in fieldwork, the size and weight of testing equipment are critical. Custom designs can prioritize portability without sacrificing functionality.

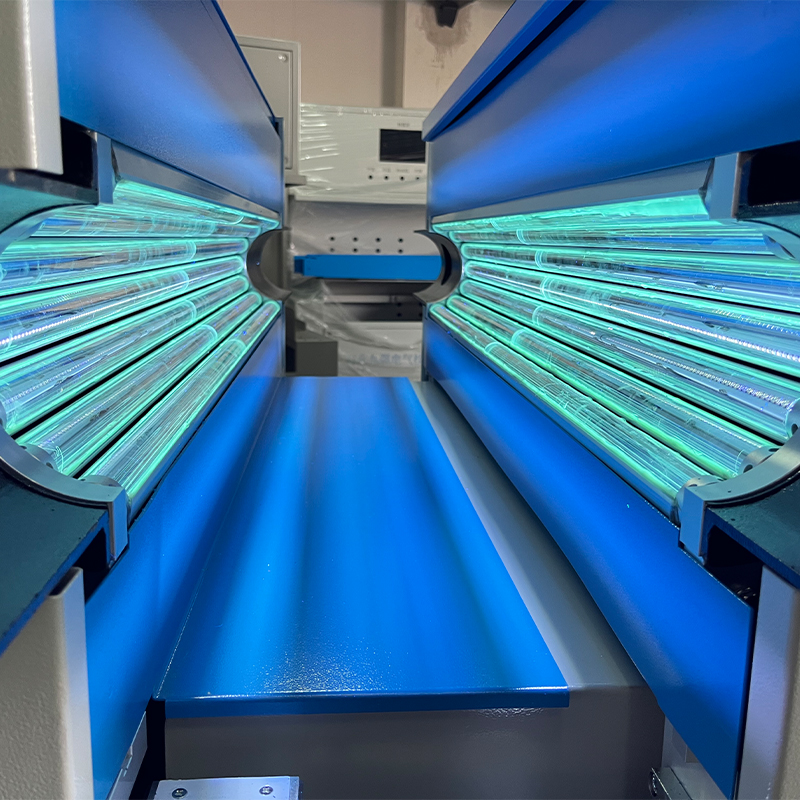

custom ac resistance tester

5. User Interface and Connectivity Different users have varying preferences regarding user interfaces and connectivity options. Customized testers can be designed with user-friendly interfaces, touch screens, or even wireless connectivity options for easy data transmission.

6. Environmental Durability In certain environments, testers must withstand harsh conditions, such as excessive moisture, dust, or extreme temperatures. Custom solutions can incorporate rugged features for enhanced durability.

Applications of Custom AC Resistance Testers

Custom AC resistance testers are employed across various sectors, including

- Power Generation and Distribution In substations and power plants, monitoring the resistance of transformer windings and busbars is vital for operational integrity. - Manufacturing In production lines, ensuring the quality and reliability of electrical components is essential. Custom testers help manufacturers maintain high standards.

- Renewable Energy In solar and wind energy installations, testing the resistance of connections and components ensures efficiency and safety.

- Telecommunications For communication systems, ensuring connections have appropriate resistance helps maintain signal quality.

Conclusion

Investing in a custom AC resistance tester can be crucial for industries reliant on electrical systems. By catering to specific measurement needs, enhancing functionality, and ensuring compliance with industry standards, these tailored solutions can significantly improve maintenance accuracy and reliability. As technology advances, we can expect further innovations in this field, making it essential for businesses to stay updated on the latest tools and techniques available for their electrical testing needs. Whether for routine checks or critical assessments, a custom AC resistance tester can prove invaluable in achieving safe and efficient operations in any electrical environment.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy