Custom Aging Test Oven for Precise Material Durability Assessment and Performance Evaluation

Understanding Custom Aging Test Ovens A Comprehensive Overview

In today's fast-paced manufacturing landscape, the ability to ensure product durability and reliability has never been more critical. Among the various methods employed to assess and validate the longevity of materials and products, custom aging test ovens play a pivotal role. This article aims to explore the significance, functionality, and benefits of custom aging test ovens in material testing.

What is a Custom Aging Test Oven?

A custom aging test oven is a specialized piece of equipment designed to simulate the aging process of materials under controlled conditions. Unlike standard ovens, which may have fixed parameters, custom aging test ovens can be tailored to meet specific requirements, enabling manufacturers to replicate real-world aging conditions relevant to their products. This includes factors such as temperature fluctuations, humidity levels, and exposure to specific gases or chemicals.

Importance of Aging Tests

Aging tests are crucial for several reasons. First and foremost, they help assess a product's lifespan, durability, and performance over time. For instance, in the aerospace and automotive industries, components are subjected to rigorous aging tests to ensure they can withstand extreme environments without degradation. Similarly, consumer electronics manufacturers utilize aging tests to guarantee product reliability and customer satisfaction.

Moreover, aging tests can identify potential failure points, allowing engineers to make design improvements before products are released to the market. In industries where safety is paramount, such as healthcare and pharmaceuticals, understanding how materials behave over time can be a matter of life and death.

Customization Features

One of the key advantages of custom aging test ovens is their ability to be tailored to specific testing protocols

. These ovens can be equipped with1. Precise Temperature Control Ability to maintain consistent temperatures across a wide range, from sub-zero to high-heat conditions, ensuring accurate simulation of aging processes.

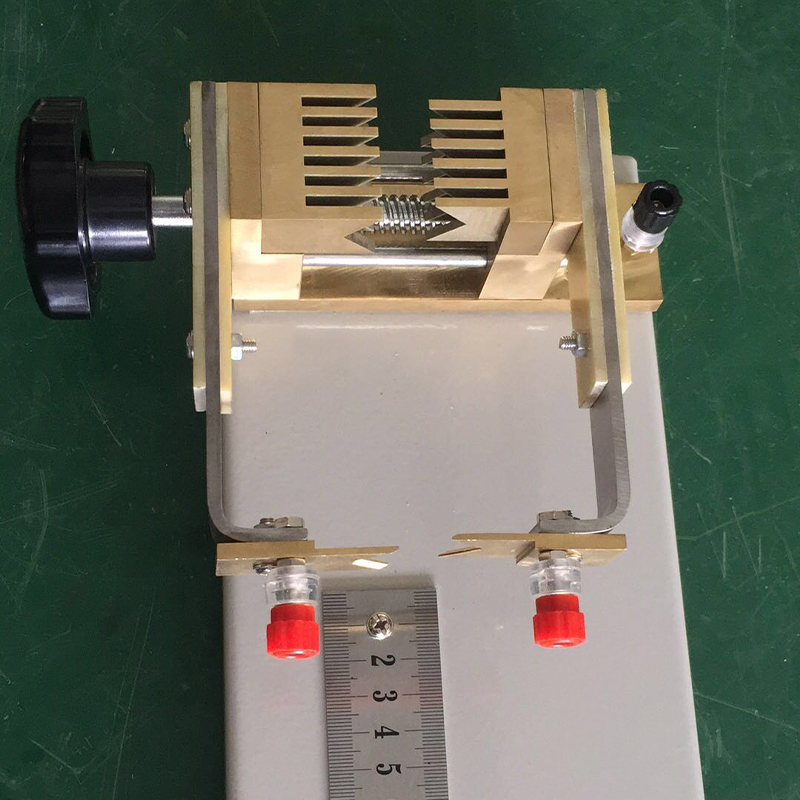

custom aging test oven

2. Humidity Control Options for adding humidity to the environment, replicating conditions that materials may face in various climates.

3. Programmable Cycles Customizable programs that can run specific aging simulations, allowing for complex testing protocols that replicate unique aging scenarios.

4. Data Logging and Monitoring Advanced models come equipped with digital monitoring systems that log temperature, humidity, and other relevant data, providing manufacturers with real-time insights into the aging process.

5. Safety Features Enhanced safety designs ensure that the ovens can operate without risk, protecting both the equipment and the personnel involved in the testing process.

Applications of Custom Aging Test Ovens

The versatility of custom aging test ovens allows them to be utilized across numerous industries. In the automotive sector, they are used to test rubber and plastic components for fatigue and degradation. In electronics, circuit boards and plastic housings undergo accelerated aging tests to predict failure rates. Additionally, the food and beverage industry uses aging test ovens to study the shelf life and stability of packaging materials.

Conclusion

Custom aging test ovens are indispensable tools in the realm of product testing and material validation. By simulating real-world aging conditions, these ovens enable manufacturers to predict product performance, enhance durability, and ensure safety. The ability to customize these ovens to meet specific testing protocols further amplifies their utility, allowing industries to tailor their testing processes to align with unique product requirements. As industries continue to demand higher quality and greater reliability, the role of custom aging test ovens will undoubtedly grow, solidifying their place as a cornerstone in material testing and product development.

In summary, investing in a custom aging test oven not only advances manufacturing capabilities but also enhances overall product quality, offering a competitive edge in today’s market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy