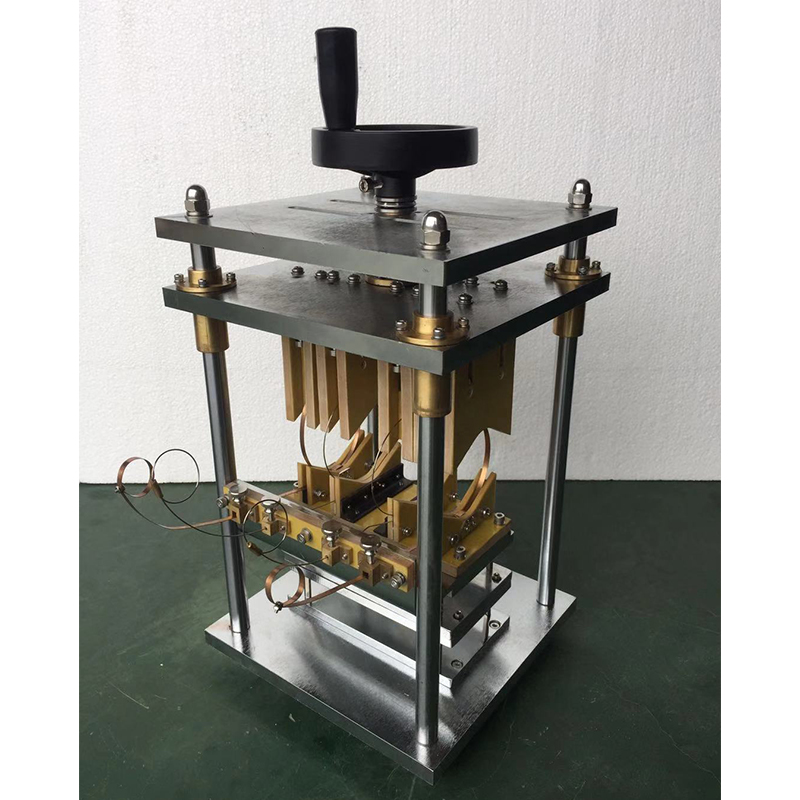

custom a traditional tensile tester

Customizing a Traditional Tensile Tester Enhancing Precision and Performance

In the realm of materials testing, the tensile tester stands as a pivotal instrument, employed to determine the mechanical properties of materials under tension. Traditional tensile testers have long served various industries, including construction, manufacturing, and research. However, as the demand for precision and adaptability grows, the customization of these testers has gained prominence. This article delves into the importance of customizing traditional tensile testers and the benefits it brings to various sectors.

The Importance of Tensile Testing

Before exploring customization, it’s essential to understand the role of tensile testing. Tensile testing helps ascertain critical material attributes, including tensile strength, yield strength, elongation, and modulus of elasticity. These parameters are vital for ensuring that materials can withstand stress without failing, making tensile testers indispensable in quality control and research and development processes.

Customization A Necessity for Modern Applications

Traditional tensile testers often come with standardized settings and capabilities. While these features may suffice for general applications, the need for customization arises in specialized contexts. Different materials exhibit unique behaviors when subjected to tensile forces, and a one-size-fits-all approach may overlook important testing nuances.

Customization can take various forms

1. Modifying Load Cell Capacity Custom testers can be equipped with load cells that accommodate specific weight ranges. This ensures accurate measurements across different materials, from flexible polymers to high-strength alloys.

2. Adaptive Gripping Mechanisms Traditional grips might not effectively hold all material types, leading to slippage or uneven stress distribution. Custom grips can be designed for specific geometries or surface finishes, enhancing the reliability of testing results.

3. Temperature and Environmental Control Certain applications require tensile testing under specific environmental conditions. Customizable temperature controls or humidity chambers can be integrated into tensile testers, allowing for more precise evaluation of material performance during thermal expansion or contraction.

custom a traditional tensile tester

4. Software Customization Advanced tensile testers nowadays often come with sophisticated software that allows for real-time data analysis and reporting. Custom software can be tailored to meet specific laboratory needs, including unique test protocols, data storage solutions, and user interfaces.

5. Incorporating Multi-Axial Testing Capabilities Traditional tensile tests typically apply force in a single direction. However, many materials experience multi-axial stress in real-world conditions. Custom testers can be designed to apply forces in multiple directions, providing a more comprehensive understanding of material behavior.

Benefits of Customization

The advantages of customizing traditional tensile testers are manifold

- Enhanced Accuracy Custom setups designed for specific materials can yield more accurate results, reducing the margin of error and leading to reliable data.

- Increased Efficiency Customized testers can streamline the testing process, greatly reducing the time required to perform multiple tests and thus accelerating product development timelines.

- Greater Versatility A customized tensile tester can be adapted for various materials and applications, making it a more valuable asset for laboratories and manufacturers that handle diverse products.

- Improved Compliance For industries governed by strict regulatory standards, customized testers can be tailored to ensure compliance with international testing protocols, avoiding costly penalties and recalls.

Conclusion

As industries evolve and the materials used in manufacturing become increasingly complex, the significance of customizing traditional tensile testers cannot be overstated. By tailoring these instruments to meet specific testing needs, businesses can enhance accuracy, efficiency, and value in their materials testing processes. The investment in a customized tensile tester not only yields benefits during the testing phase but also ensures that the end products meet quality standards necessary for success in a highly competitive marketplace. In a world driven by innovation, the ability to customize equipment to align with operational goals is not merely advantageous but essential.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy