Tailored Precision Measurement Solutions for Advanced Projectors

Custom Automatic Measuring Projector A Revolution in Precision Measurement

In the world of manufacturing and quality control, precision is paramount. As industries continue to evolve, the need for advanced measuring technologies has become increasingly critical. One such innovation making waves in this space is the custom automatic measuring projector, a cutting-edge tool designed to enhance accuracy, efficiency, and user-friendliness in measurement processes.

Understanding the Basics

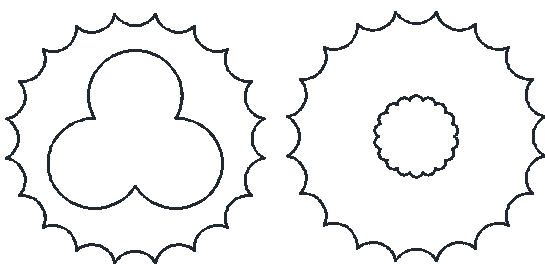

A measuring projector, commonly known as an optical comparator, is an instrument that allows for the evaluation of detailed dimensions of a workpiece. Traditionally, these devices use a simple lens to project a magnified silhouette of the object onto a screen, where operators can take measurements against predefined standards. However, with the advent of technology, the focus has shifted toward automation and customization to cater to diverse manufacturing needs.

The modern custom automatic measuring projector integrates advanced optical technology with automated mechanisms, enabling users to measure complex geometries with minimal manual intervention. This hybrid approach not only streamlines the measurement process but also enhances repeatability and reduces the chances of human error.

Key Features and Benefits

1. Automation for Efficiency One of the standout features of custom automatic measuring projectors is their automation capability. By leveraging computer numerical control (CNC) and advanced software, these projectors can perform measurements, adjustments, and data logging without constant user oversight. This automation significantly reduces measurement time, allowing equipment operators to focus on other critical tasks.

2. High Precision and Accuracy Custom projectors are equipped with high-resolution optics and sensors that deliver precise measurements. Their automatic calibration features ensure accuracy over time, providing users with reliable data for quality control. This high level of precision is essential for industries such as aerospace, automotive, and electronics, where even the slightest deviation can lead to significant consequences.

custom automatic measuring projector

3. Customizable Solutions A major advantage of custom automatic measuring projectors is their ability to be tailored to specific needs. Different industries have varying measurement requirements, and these projectors can be designed with specialized optics, software, and fixtures to address unique challenges. Whether it’s measuring intricate components in micromachining or large parts in heavy machinery, customization ensures the projector meets precise specifications.

4. User-Friendly Interface Modern measuring projectors come equipped with intuitive interfaces that simplify the measurement process. With touchscreens, guided workflows, and visual representations, operators can quickly learn to use the equipment without extensive training. This accessibility makes it easier for teams to adopt new technologies and improve overall productivity.

5. Data Management and Integration In today's data-driven environment, the ability to collect and analyze measurement data is crucial. Most custom automatic measuring projectors are compatible with advanced software solutions that enable seamless data management, reporting, and integration with existing manufacturing execution systems (MES). This connectivity facilitates real-time monitoring, enhancing the decision-making process and ensuring compliance with quality standards.

Applications Across Industries

From small-scale workshops to large manufacturing facilities, custom automatic measuring projectors are being utilized in various sectors. In the automotive industry, they play a vital role in verifying the dimensions of critical components, such as engine parts and chassis. In the electronics sector, they help ensure the high precision of circuit boards and semiconductor components. Additionally, industries like medical devices and aerospace rely on these projectors to maintain rigorous quality standards.

Conclusion

The emergence of custom automatic measuring projectors marks a significant advancement in measurement technology. By combining automation, precision, and customization, these devices provide a robust solution for manufacturers striving for excellence in quality control. As industries continue to demand higher standards and efficiencies, the adoption of such innovative measuring tools will undoubtedly play a crucial role in driving progress and securing competitive advantages in the marketplace. Embracing this technology will not only enhance operational capabilities but also pave the way for a more precise and efficient future in manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy