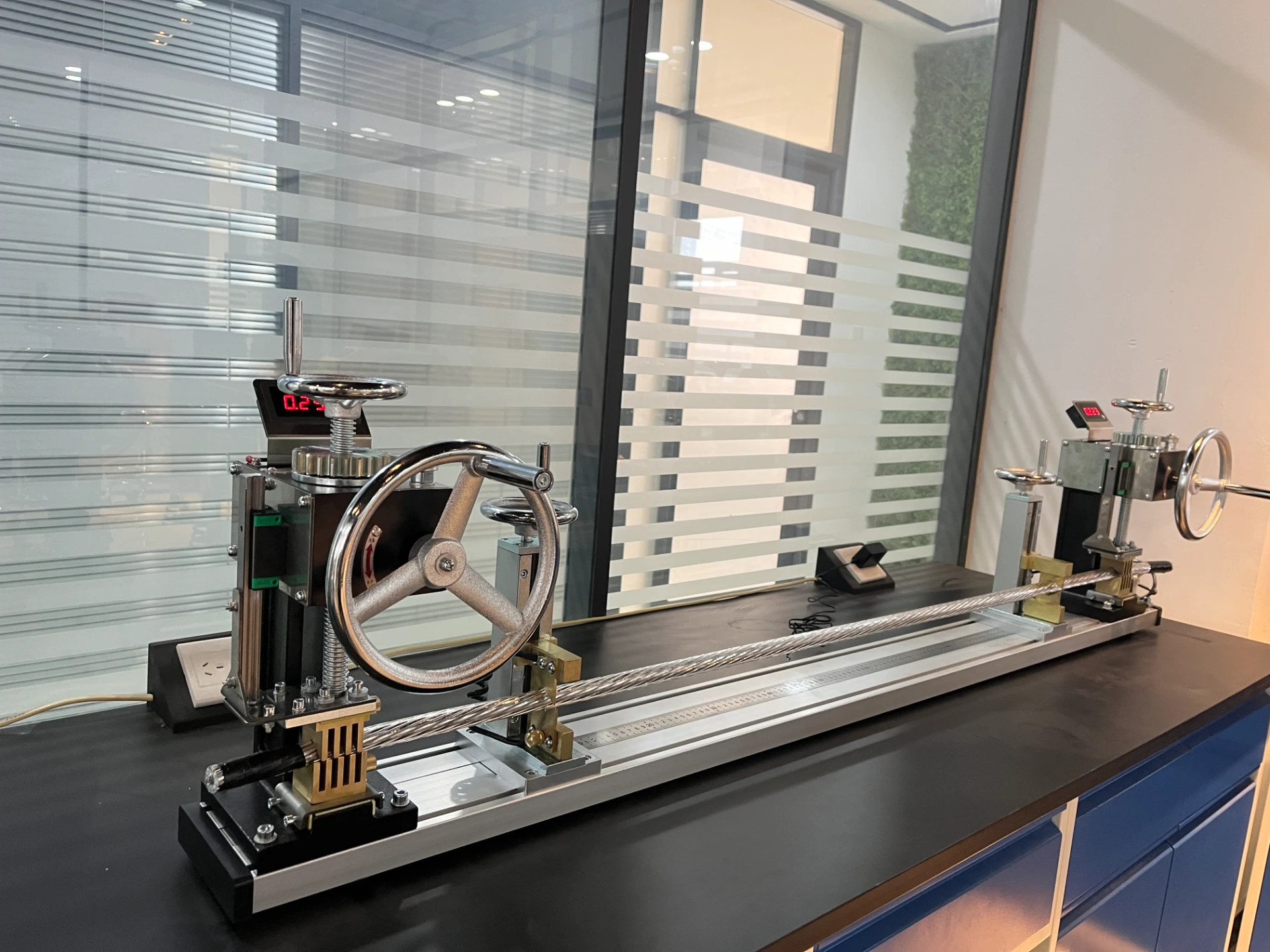

Durable Cable Testing Device for Repeated Bending and Flexibility Assessment

The Importance of Custom Cable Repeated Bending Testers

In the ever-evolving world of technology and engineering, ensuring the reliability and durability of cables has become paramount. With cables being an essential component in various applications, from telecommunications to automotive systems, the need for rigorous testing has led to the development of specialized equipment like the custom cable repeated bending tester.

Understanding the Need for Cable Testing

Cables are subjected to various mechanical stresses during their lifetime, especially in environments where they are frequently bent or flexed. This is particularly true for mobile devices, industrial machinery, and any application where cables connect components that may move or shift. Over time, repeated bending can lead to wear and tear, which can affect performance, lead to malfunctions, or even pose safety risks. Therefore, manufacturers must ascertain the longevity and functionality of cables under repeated bending stresses.

The Design of Custom Cable Repeated Bending Testers

Custom cable repeated bending testers are specifically designed to mimic real-world cable usage scenarios. These testers can replicate the dynamics of bending, twisting, and flexing that cables would experience in actual conditions. Unlike standard testing equipment, which may not reflect specific user requirements or application conditions, custom solutions can be tailored to meet the nuances of various cable types and bending specifications.

Typically, these testers feature adjustable parameters such as angle, speed, and frequency of bending. This allows manufacturers to conduct thorough assessments that simulate the exact environments in which the cables will operate. Additionally, these testers often incorporate sensors and software to track performance metrics, providing valuable data that can influence design enhancements.

Benefits of Using Custom Cable Repeated Bending Testers

custom cable repeated bending tester

1. Enhanced Reliability By thoroughly testing cables under controlled conditions that replicate actual usage, manufacturers can identify potential failure points before products reach the market. This leads to improved product reliability.

2. Quality Assurance Custom testers ensure that each cable meets specific industry standards and customer requirements. This level of quality assurance can set a company apart from its competitors and build trust with consumers.

3. Cost Efficiency Although the initial investment in custom testing equipment may be higher, the long-term savings from reduced warranty claims, recalls, and enhanced customer satisfaction can more than offset these costs.

4. Innovation and Design Improvement Continuous testing and feedback allow for design iteration, leading to better-performing cables. Manufacturers can experiment with materials and constructions that may enhance durability under bending stresses.

5. Regulatory Compliance Many industries require compliance with stringent safety and performance standards. Custom cable repeated bending testers can be designed to adhere to these guidelines, helping manufacturers remain compliant and avoid potential penalties.

Conclusion

In conclusion, as technology continues to advance, the importance of reliable cable performance cannot be understated. Custom cable repeated bending testers play a crucial role in validating the durability and functionality of cables under realistic bending conditions. By investing in such specialized testing equipment, manufacturers can ensure not only the quality and safety of their products but also foster innovation that will keep pace with the changing demands of the market. The integration of accurate and thorough testing processes is an indispensable strategy for success in an increasingly competitive landscape, ultimately leading to enhanced user satisfaction and brand loyalty.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy