Custom Cable Cutter for Precision Slicing and Efficient Cable Management Solutions

Custom Cable Slicer A Game Changer for Electronics and Telecommunications

In an age where precision and efficiency are paramount in the electronics and telecommunications industries, the custom cable slicer emerges as a vital tool. This innovative device not only enhances productivity but also ensures that cables are sliced with utmost accuracy, meeting the needs of various applications ranging from manufacturing to field installations. Let’s delve into what makes custom cable slicers essential, their benefits, and how they are transforming the way we handle cable installations.

Understanding Custom Cable Slicers

A custom cable slicer is a specialized machine designed to cut cables of various types and sizes to specific lengths as per the requirements of a project. Unlike standard cable cutting tools, a custom slicer allows for tailored specifications which can accommodate multiple cable types including coaxial, fiber optic, and power cables. The ability to customize settings means that operators can adjust the blade speed, angle, and pressure to suit different materials, thereby ensuring a clean and precise cut every time.

Benefits of Using Custom Cable Slicers

1. Precision Cutting One of the foremost advantages of using a custom cable slicer is the precise cuts it provides. Accurate cutting reduces waste and ensures consistent lengths across bulk production runs, which is crucial for industries that demand high standards of quality.

2. Increased Efficiency Manual cable cutting can be labor-intensive and time-consuming. Custom cable slicers automate this process, dramatically increasing throughput. This efficiency not only speeds up production times but also allows workers to focus on other critical tasks.

3. Versatility Custom slicers can be designed to handle a wide range of cable types and specifications, making them versatile tools for any workshop. Whether you are working with single-core cables or multi-core assemblies, a custom slicer can be tailored to meet various demands.

4. Cost-Effectiveness Although the initial investment in a custom cable slicer may be significant, the long-term savings are noteworthy. By reducing material waste and enhancing productivity, these machines ultimately lower the cost per unit in cable production and installation.

custom cable slicer

5. Reduced Risk of Injuries The automated system of custom cable slicers minimizes the risk of accidents that often occur with manual cutting tools. By reducing human interaction with sharp blades, companies can foster a safer working environment.

Applications and Industries

Custom cable slicers find applications across a myriad of industries. In the telecommunications sector, they play a crucial role in the manufacture of various types of cables used in networking and signal transmission. Similarly, in the automotive industry, precise cable slicing ensures that wiring harnesses meet exact specifications, reducing the likelihood of failures in electrical systems.

The medical field also benefits from custom cable slicing, as specialized medical equipment often relies on precise cable lengths to maintain functionality and safety. Moreover, in the renewable energy sector, custom slicers are employed to handle the specific needs of solar and wind energy cabling, underscoring the versatility of these machines.

The Future of Cable Slicing Technology

As technology continues to evolve, so do the capabilities of custom cable slicers. Innovations such as integration with smart technology and IoT (Internet of Things) are paving the way for enhanced functionality. Future models may feature real-time monitoring, predictive maintenance, and even AI-driven adjustments to optimize the cutting process even further.

Moreover, with the growing emphasis on sustainability, manufacturers are looking for ways to design custom cable slicers that minimize waste and energy consumption. The shift towards environmentally-friendly practices in production is an important trend that will shape the future of cable cutting technologies.

Conclusion

Custom cable slicers represent a significant advancement in the way cables are manufactured and installed. With their precision, efficiency, and versatility, these machines are transforming industries by reducing production costs, enhancing safety, and ensuring high-quality outcomes. As technology continues its rapid evolution, we can expect even more innovative features that will further solidify the place of custom cable slicers in a variety of sectors, paving the way for a more efficient and sustainable future in cable handling and installation.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

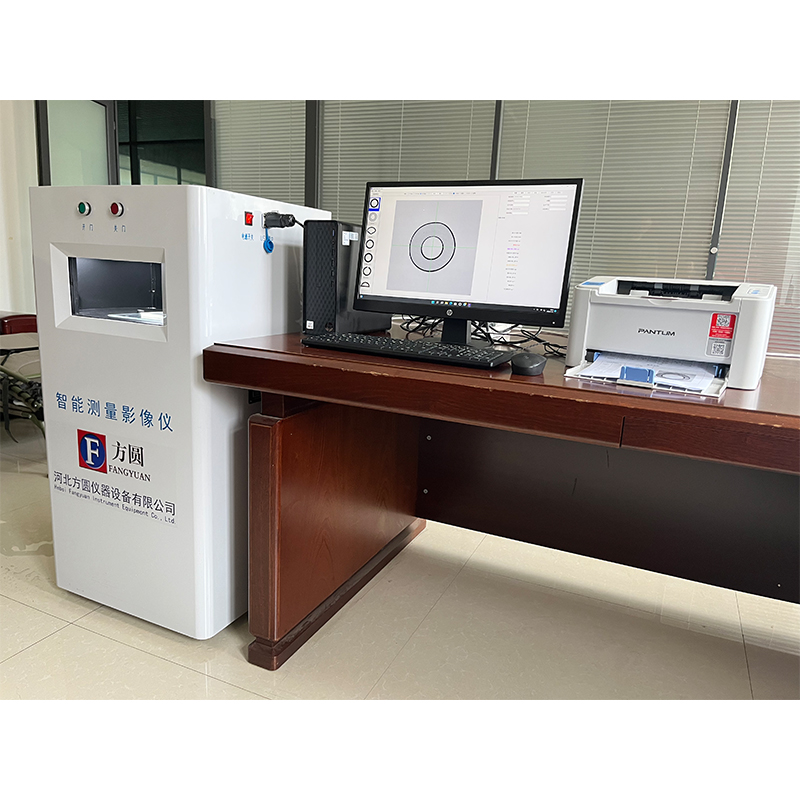

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy