custom conductor resistance constant temperature test

Custom Conductor Resistance Constant Temperature Test

In the ever-evolving world of electrical engineering, the significance of understanding conductor resistance cannot be overstated. The resistance of conductors plays a critical role in determining the efficiency and performance of electrical circuits. Among the various methods employed to analyze conductor resistance, the constant temperature test stands out as a reliable technique. This article delves into the intricacies of custom conductor resistance testing under constant temperature conditions, highlighting its importance, methodology, and applications.

Understanding Conductor Resistance

Conductor resistance is a measure of how strongly a conductor opposes the flow of electric current. Several factors influence this resistance, including the material composition of the conductor, its temperature, length, and cross-sectional area. The fundamental equation relating these factors is given by Ohm’s Law, which states that resistance \( R \) is equal to the voltage \( V \) across the conductor divided by the current \( I \) flowing through it

\[ R = \frac{V}{I} \]

As temperature increases, the resistance of most conductive materials also increases. This relationship between temperature and resistance is known as the temperature coefficient of resistance, and it is essential to control temperature during resistance testing to ensure accurate results.

The Need for a Constant Temperature Test

In practical scenarios, temperature fluctuations can significantly affect the resistance measurements of conductors. Therefore, conducting resistance tests at a constant temperature is crucial to obtaining reliable data. A constant temperature test minimizes variables, allowing for a clearer understanding of the conductor’s behavior under specific conditions. This is particularly important in applications like power transmission, where even small fluctuations in resistance can lead to inefficiencies and increased energy losses.

Methodology of the Constant Temperature Test

The constant temperature resistance test involves several key steps

1. Sample Preparation Custom conductors, which may vary in material and geometry, are prepared for testing. It is essential to ensure that the surfaces are clean and free from contaminants.

2. Temperature Control The test environment is set to maintain a specific temperature, often using temperature-controlled chambers or baths. This helps in stabilizing the temperature throughout the testing duration.

custom conductor resistance constant temperature test

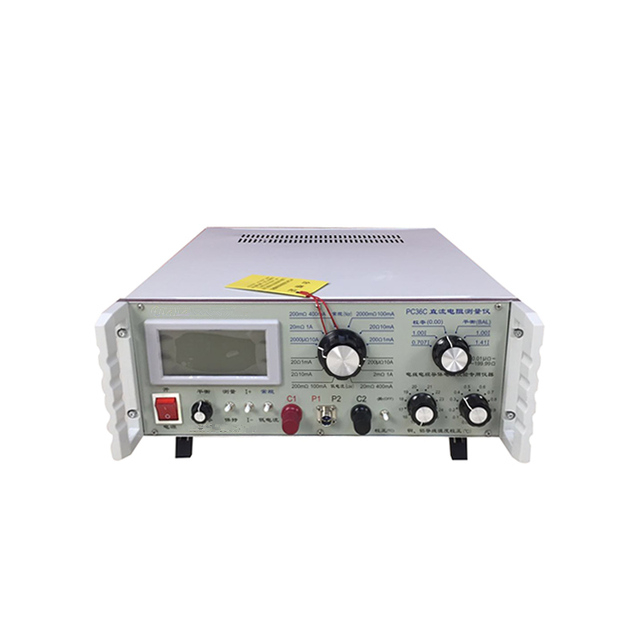

3. Measurement Setup A precision multimeter or an ohmmeter is connected to the conductor to measure resistance accurately. The test leads should be appropriately calibrated to avoid introducing additional resistance into the measurement.

4. Data Acquisition The resistance is measured after allowing the conductor to equilibrate at the set temperature. Multiple readings can be taken to ensure precision and account for any minor fluctuations.

5. Analysis The gathered data is analyzed to determine the conductor's resistance at the specified temperature. These results can then be compared with standard values or used to derive the temperature coefficient of resistance.

Applications of Constant Temperature Resistance Testing

Custom conductor resistance testing under constant temperature conditions is valuable in various fields. Some notable applications include

- Electronics Development Engineers can use these tests during the design and prototyping phases of electronics to ensure that the chosen conductors meet performance specifications.

- Power Systems In high-voltage transmission lines, understanding resistance variations can aid in optimizing energy efficiency and reducing losses.

- Material Research Researchers studying new conductive materials can use constant temperature tests to accurately characterize their properties.

- Quality Control Manufacturers can implement constant temperature resistance testing as part of their quality assurance processes to ensure that their products meet required standards.

Conclusion

The constant temperature resistance test is an essential tool in the electrical engineering domain, especially when dealing with custom conductors. By maintaining a stable temperature during testing, engineers and researchers can obtain accurate and reliable resistance measurements. This understanding not only furthers the development of more efficient electrical systems but also contributes to the advancement of materials science. As the demand for more efficient and reliable electrical conductors continues to grow, the importance of such testing methods will only increase, reinforcing their relevance in both current and future applications.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy