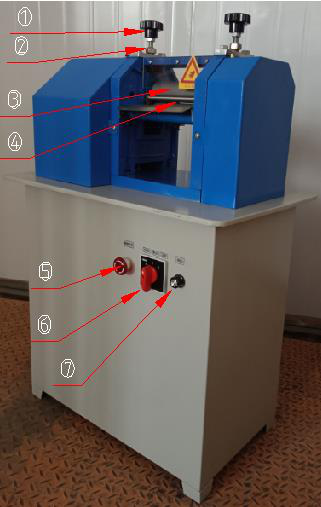

custom conductor resistance fixture

Understanding Custom Conductor Resistance Fixtures

As the demand for precision in electrical measurements increases, custom conductor resistance fixtures have emerged as essential tools across various industries. These fixtures facilitate accurate resistance measurement for conductors, which is crucial for ensuring the performance and reliability of electrical systems. This article delves into the importance, design, and applications of custom conductor resistance fixtures.

The Importance of Resistance Measurement

Resistance is a critical parameter in electrical engineering and plays a significant role in the functionality of devices. The resistance values of conductors can affect power losses, heating, and overall efficiency in electrical systems. Inaccurate resistance measurements can lead to improper system design, which may result in catastrophic failures or inefficiencies in electronic devices and electrical installations.

Custom conductor resistance fixtures ensure precision by providing a controlled environment for resistance testing. Whether in development, production, or quality control processes, these fixtures are tailored to meet specific requirements for various conductor types and applications, guaranteeing reliable and accurate measurements.

Key Features of Custom Fixtures

One of the primary advantages of custom conductor resistance fixtures is their adaptability. These fixtures can be designed to accommodate different types of conductors, including copper, aluminum, and specialized alloys. The design can vary to handle various sizes, shapes, and configurations while ensuring that contact resistance is minimized.

Moreover, custom fixtures often incorporate features such as

- Temperature Control Since resistance can vary with temperature, many fixtures come equipped with temperature monitoring and control systems. Maintaining a consistent temperature during measurement ensures that the results are nominal and reliable.

- User-friendly Interfaces Many modern fixtures include digital displays and interfaces that make it easier for operators to read and interpret results quickly. This capability enhances efficiency, especially in busy industrial environments.

- Enhanced Testing Capabilities Some custom fixtures can perform additional tests beyond simple resistance measurements, such as voltage drop tests, insulation testing, and continuity testing, making them multifunctional tools.

Designing a Custom Fixture

The design process for a custom conductor resistance fixture typically begins with an analysis of the specific application requirements

. Key considerations includecustom conductor resistance fixture

1. Conductor Specifications Understanding the type of conductor, its dimensions, and the expected range of resistance values helps in designing the most effective fixture.

2. Environmental Conditions Components may need to withstand varying environmental conditions, including humidity, temperature fluctuations, and potential exposure to chemicals or harsh environments.

3. Measurement Standards Compliance with relevant international and industry-specific standards (like ASTM, IEC, or NIST) is crucial, ensuring that the fixture meets the required accuracy and reliability for testing.

4. Integration with Testing Equipment Custom fixtures are often designed to seamlessly integrate with digital multimeters, resistance meters, or other testing instruments. This integration ensures that data collection is straightforward and minimizes errors.

Applications Across Industries

Custom conductor resistance fixtures are used in numerous industries, including

- Manufacturing In the production of electrical components, accurate resistance measurements are vital for maintaining quality standards.

- Telecommunications Testing the resistance of cabling and connectors helps ensure signal integrity and system reliability.

- Aerospace and Defense These industries demand the highest standards of precision, where custom resistance fixtures play a critical role in quality assurance.

- Renewable Energy In solar and wind energy applications, resistance testing is crucial for assessing the performance and longevity of conductors used in power generation and transmission.

Conclusion

In conclusion, custom conductor resistance fixtures are indispensable in achieving accurate and reliable resistance measurements across multiple applications. By understanding the unique requirements of various industries and utilizing tailored designs, these fixtures significantly enhance testing accuracy. With ongoing advancements in technology, the potential for more sophisticated and versatile fixtures continues to expand, making them an integral component in the future of electrical testing and quality assurance. As businesses prioritize precision and performance, investing in custom solutions will remain vital for maintaining competitive advantage and operational excellence.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy