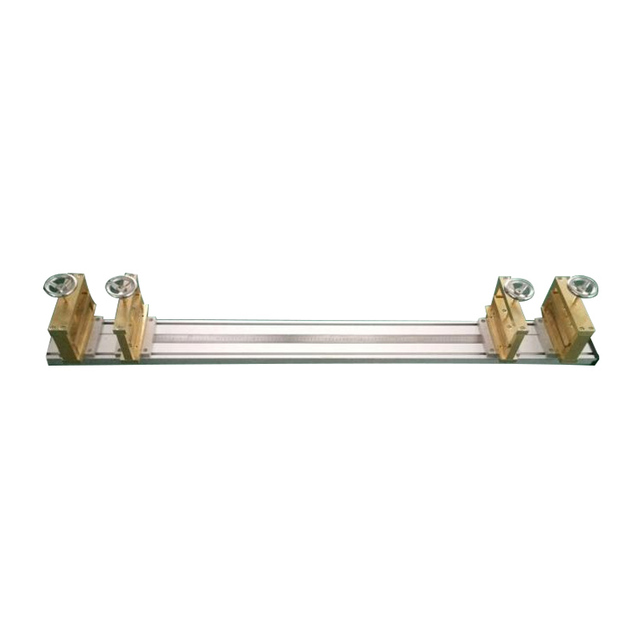

custom conductor resistance fixture

Understanding Custom Conductor Resistance Fixtures

In the world of electrical engineering, precise measurement of resistance is crucial for a wide range of applications, from designing circuits to testing components. A custom conductor resistance fixture plays a pivotal role in this measurement process, providing a highly controlled environment to determine the electrical resistance of various conductive materials. This article delves into the significance, design considerations, and potential applications of these specialized fixtures.

What is a Custom Conductor Resistance Fixture?

A custom conductor resistance fixture is an engineered setup that allows technicians and engineers to measure the resistance of conductors, such as wires, cables, and other conductive materials. Unlike standard measurement tools, these fixtures are tailored to meet specific testing requirements, ensuring accuracy and repeatability. The primary objective is to create an interface between the testing equipment and the conductor that minimizes errors in measurement due to external factors, such as temperature fluctuations or mechanical stress.

Importance of Accurate Resistance Measurement

Accurate resistance measurements are critical in various sectors, including telecommunications, automotive, aerospace, and consumer electronics. Resistance values can significantly influence the performance of electrical systems. For instance, high resistance in a connector might lead to heat generation, inefficiencies, or even system failures. Therefore, the ability to precisely quantify resistance can aid in quality control, design validation, and compliance with industry standards.

Design Considerations

When designing a custom conductor resistance fixture, several factors must be taken into account

1. Type of Conductors Fixtures must be designed to accommodate various types of conductive materials, including copper, aluminum, and specialty alloys. The design should consider the physical and electrical properties of each material.

2. Measurement Range Based on the expected range of resistance values, the fixture should be capable of measuring low resistances (often in milliohms) as well as higher resistances (ohms) without compromising accuracy.

3. Environment The testing environment can greatly affect resistance measurements. Factors such as humidity, temperature, and electromagnetic interference need to be controlled to ensure reliable results.

4. Connection Interface The fixture must ensure a stable and repeatable connection between the measurement device and the conductor. This often involves specialized clamping mechanisms or contact points that minimize contact resistance.

custom conductor resistance fixture

5. Calibration Regular calibration of the fixture is essential to ensure ongoing accuracy. The design should incorporate features that allow for easy calibration with standard resistors.

6. Safety and Compliance Depending on the application, the fixture might need to meet various safety and compliance standards. Materials used in construction must be durable and safe for the intended environment.

Applications of Custom Conductor Resistance Fixtures

Custom conductor resistance fixtures find application in several areas

1. Electrical Component Testing Manufacturers use these fixtures to test the resistance of connectors, switches, and other components to ensure they meet specifications.

2. Research and Development Engineers developing new materials or technologies employ these fixtures to gather essential data on material performance under different conditions.

3. Quality Assurance In production lines, custom fixtures enable rapid testing of electrical components to ensure quality before shipment, preventing failures in the field.

4. Educational Purposes In academic settings, these fixtures can be used for laboratory exercises that focus on understanding resistance and the principles of electrical conduction.

5. Field Testing Portable versions of resistance fixtures are used by technicians on-site to evaluate the condition of conductive paths in existing installations.

Conclusion

Custom conductor resistance fixtures are indispensable tools in the realm of electrical measurement. By providing a controlled environment for resistance measurement, these fixtures enable engineers and technicians to ensure the reliability and efficiency of conductive materials and components. As technology advances, the continued development of these fixtures will play a crucial role in enhancing the precision and application of resistance measurements across various industries. In summary, investing in a high-quality custom conductor resistance fixture is not only beneficial—but essential—for ensuring the integrity and performance of electrical systems.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy