Custom Equipment for Measuring Wire Resistance in Conductor Applications

Custom Conductor Resistance Measurement Equipment Enhancing Precision in Electrical Testing

In the realm of electrical engineering, the accurate measurement of conductor resistance is crucial for ensuring the efficiency and reliability of electrical systems. Various applications, from power distribution to electronic device manufacturing, require tools that deliver precise measurements of conductor resistance. Custom conductor resistance measurement equipment has emerged as a vital solution tailored to meet specific needs across different industries.

The significance of measuring conductor resistance cannot be overstated. Resistance measurements help assess the performance and integrity of electrical connections, identify potential faults, and ensure compliance with industry standards. Traditional measurement methods, such as the four-wire method, have been widely employed. However, the introduction of custom measurement equipment allows for enhanced accuracy, speed, and adaptability in testing procedures.

Custom equipment is designed with unique specifications tailored to the requirements of the application at hand. This means that industries dealing with specific materials, dimensions, or environmental conditions can benefit from bespoke solutions. For instance, the mining, renewable energy, and telecommunications sectors rely on equipment that can withstand harsh environments while providing accurate measurements. Custom equipment can be engineered to operate under extreme temperatures, humidity levels, or in high-vibration settings, ensuring that reliability is maintained regardless of external conditions.

custom conductor resistance measurement equipment

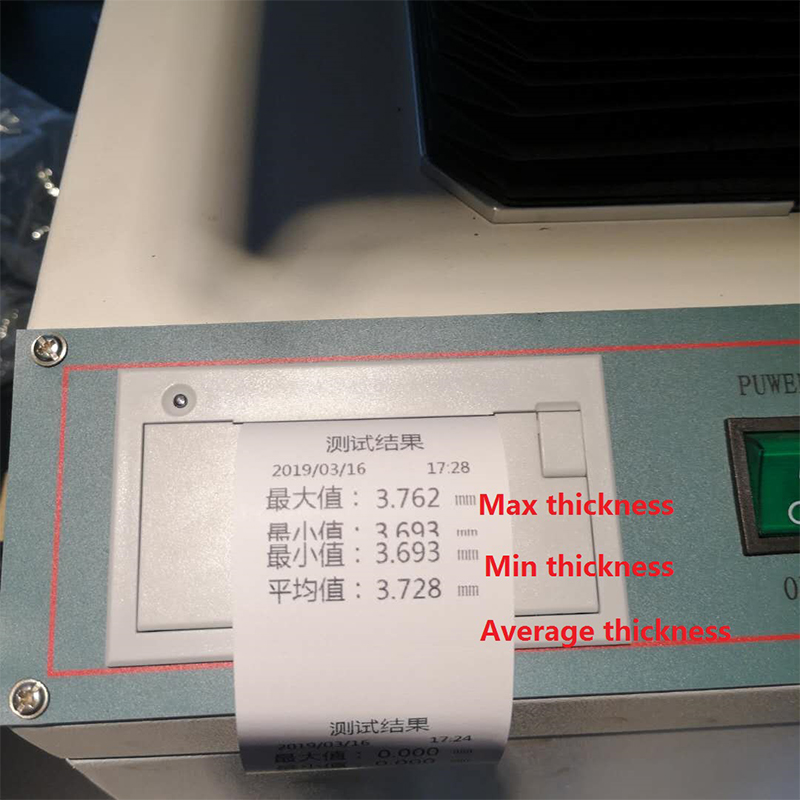

One of the critical advantages of custom conductor resistance measurement equipment is its capability to integrate advanced technology. Many systems now come equipped with digital displays, data logging features, and connectivity options that allow for real-time monitoring and analysis. Users can send data directly to cloud-based platforms for remote analysis, enhancing decision-making processes. This level of automation not only simplifies operations but also reduces the risk of human error, leading to more reliable results.

The design of custom measurement equipment often incorporates user-friendly interfaces. This ensures that operators, regardless of their technical expertise, can easily navigate the system. With intuitive designs and comprehensive training resources, organizations can minimize downtime and increase productivity. Furthermore, ongoing support services provided by manufacturers ensure that the equipment remains calibrated and functional over time, thus maintaining accuracy in resistance measurements.

In selecting custom conductor resistance measurement equipment, it is essential to consider various factors, including the measurement range, accuracy requirements, and the specific applications it will be used for. Consulting with experienced manufacturers can provide valuable insights into the best configurations and technologies for particular use cases.

In conclusion, custom conductor resistance measurement equipment plays a pivotal role in improving the precision of electrical testing across various industries. By addressing specific needs and incorporating advanced technologies, these tailored solutions enhance reliability, streamline operations, and ultimately contribute to increased safety in electrical systems. Whether it’s in a manufacturing plant or an outdoor renewable energy site, the importance of specialized equipment cannot be overstated; it represents the future of electrical testing, ensuring that systems function optimally and safely in an ever-evolving technological landscape.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy