Custom DC Insulation Resistance Measurement Device for Accurate Testing and Analysis

Custom DC Insulation Resistance Tester A Comprehensive Overview

In the realm of electrical testing, ensuring the integrity of insulation is paramount for the safety and efficiency of electrical systems. One of the critical instruments used for this purpose is the DC insulation resistance tester. While standard models are widely available, the demand for custom-designed testers has been on the rise to meet the specific needs of various industries. This article explores the significance, features, and advantages of custom DC insulation resistance testers.

Importance of Insulation Resistance Testing

Insulation resistance testing plays a crucial role in maintaining electrical safety. It is a preventive measure designed to detect potential insulation failures that could lead to equipment damage, operational hazards, or even catastrophic failures. Regularly assessing insulation resistance helps in identifying issues before they escalate, ensuring system reliability and compliance with safety regulations.

DC insulation resistance testers apply a direct current to the insulation material and measure the resistance offered. A higher resistance reading indicates better insulation quality, while lower readings signal potential degradation or failure. This testing is particularly essential in high-voltage applications, transformer maintenance, and preventive maintenance programs.

The Case for Customization

While off-the-shelf insulation testers serve general purposes, custom DC insulation resistance testers offer several advantages that can be critical for specific applications. Customization allows for the integration of unique features tailored to the operational environment and user requirements. Here are some reasons why custom testers are becoming increasingly popular

1. Specific Testing Requirements Different industries have varying testing standards and requirements. For example, wind energy, railways, or manufacturing industries may require specific ranges of voltages or unique testing protocols. Custom testers can be designed to meet these specific needs.

2. Enhanced User Interface The user interface can be customized to improve usability, ensuring that operators can efficiently utilize the tester. This might include touch screens, programmable settings, and data logging capabilities that can be tailored for specific applications.

3. Durability and Design In harsh environments, standard testers may fail to withstand the conditions. Custom designs can incorporate robust housing, weatherproofing, and shock resistance, making them suitable for outdoor or industrial applications.

4. Integration with Other Systems Many organizations seek to integrate their testing equipment with existing software or monitoring systems. Custom testers can be designed with communication protocols that allow seamless data transfer and integration into maintenance management systems.

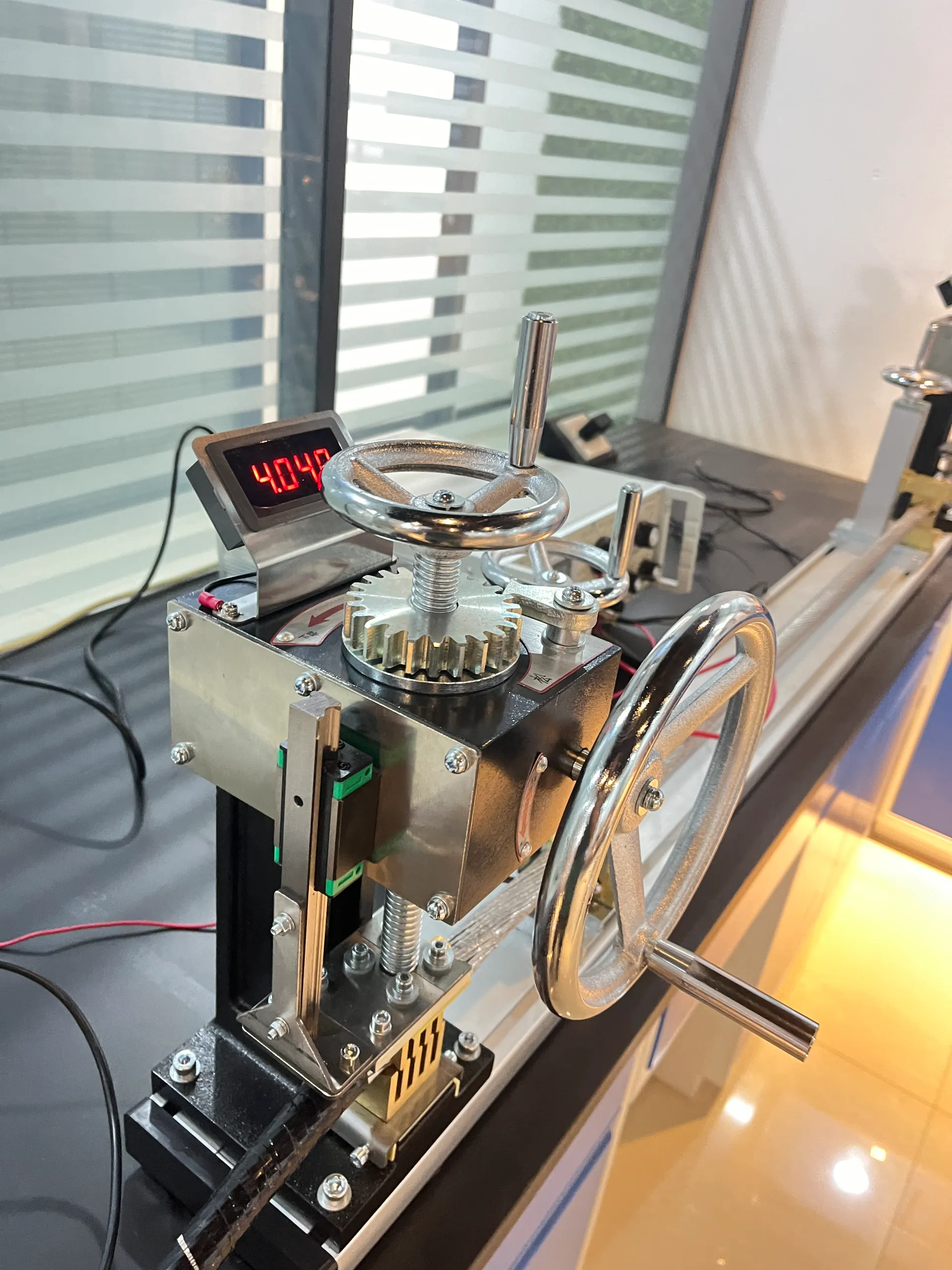

custom dc insulation resistance tester

Key Features to Consider

When selecting or designing a custom DC insulation resistance tester, certain features are crucial to ensure optimal performance

- Voltage Range The ability to test at various voltage levels is essential for comprehensive insulation checks across different applications.

- Resistance Measurement Range A wide measurement range allows for effective testing of both low and high-resistance insulations.

- Data Logging Capabilities This feature enables users to record test results for later analysis, aiding in long-term maintenance planning and reporting.

- Portability A lightweight and compact design enhances the tester's usability on-site.

- Battery Life Extended battery life is vital for field testing, allowing for uninterrupted operations.

Conclusion

Custom DC insulation resistance testers represent a vital evolution in electrical testing technology. By meeting specific industry needs and enhancing operational efficiency, these instruments play a critical role in ensuring safety and reliability in electrical systems. Whether for preventive maintenance or compliance testing, investing in a customized solution could be the key to operational success in many sectors. As industries continue to evolve, so too will the demand for tailored testing solutions that ensure the integrity of electrical insulation remains uncompromised.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy