custom electronic tensile tester

Custom Electronic Tensile Tester Elevating Material Testing Standards

In an era where precision and reliability are paramount, the demand for high-quality testing equipment has surged across various industries. One pivotal instrument that has gained prominence is the electronic tensile tester. Specifically, custom electronic tensile testers have become increasingly relevant, allowing businesses to tailor testing processes to their unique requirements. This article explores the significance, applications, and benefits of custom electronic tensile testers in material testing.

Understanding Electronic Tensile Testers

A tensile tester, commonly known as a tensile testing machine, is designed to measure the tensile strength, elongation, and other essential properties of materials. It performs this by applying a controlled tensile force to a sample until it breaks or yields, providing valuable data on the material’s performance characteristics. Electronic tensile testers utilize advanced sensors and software to ensure accurate measurements and can be customized to fit various testing protocols.

Importance of Customization

One of the primary advantages of a custom electronic tensile tester is its ability to accommodate specific testing needs. Different materials—be it metals, polymers, or composites—exhibit varying behaviors under stress, necessitating tailored testing conditions. Customization allows for

1. Variable Load Cells Select load cells based on the expected range of tensile strength of the samples, ensuring high precision and preventing overloads during testing.

2. Testing Speed Adjustments Different materials require different rates of testing. Custom electronic tensile testers can be engineered to adjust speed parameters to fulfill unique material specifications.

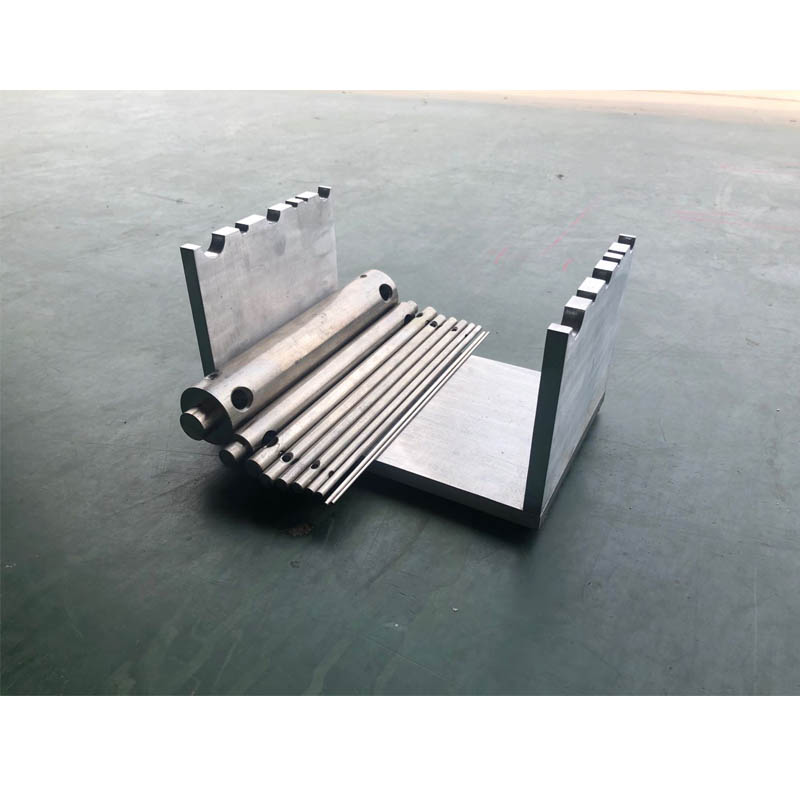

3. Specialized Fixtures Custom grip and fixture designs facilitate the testing of irregularly shaped or sized specimens, ensuring that the materials are held securely and tested accurately.

4. Data Acquisition Needs Custom systems can integrate with existing data management software, allowing for seamless data collection, analysis, and reporting tailored to industry standards.

Applications Across Industries

Custom electronic tensile testers find application in a variety of sectors, including

custom electronic tensile tester

- Manufacturing In industries such as aerospace, automotive, and construction, tensile testing is crucial for assessing the strength and durability of materials used in production. Aerospace companies, for example, rely on tensile test results to ensure that lightweight materials maintain integrity under extreme conditions.

- Research and Development Material scientists and engineers utilize tensile testers to develop new materials or improve existing ones. Customized setups allow for innovative testing approaches that fuel advancements in material properties, resilience, and performance.

- Quality Control Businesses committed to quality assurance use tensile testing as a routine measure to verify that raw materials and finished products meet required specifications. Custom electronic tensile testers can be aligned with specific quality standards, ensuring consistent and reliable testing results.

- Education and Training Academic institutions use electronic tensile testers for both teaching and research. Custom configurations can be set up for students to explore various failure modes and material behaviors, fostering a deeper understanding of material science concepts.

Benefits of Custom Electronic Tensile Testers

The implementation of custom electronic tensile testers brings numerous benefits, including

- Enhanced Accuracy Customization ensures the equipment is calibrated to the specific needs of the materials being tested, resulting in more precise measurements and data analysis.

- Increased Efficiency Tailored solutions optimize testing processes, reducing setup times and increasing throughput, thus enabling companies to conduct more tests in a shorter time frame.

- Cost-Effectiveness By investing in a custom solution, businesses can reduce operational costs associated with inaccurate testing, re-testing, and material wastage.

- Scalability Custom electronic tensile testers can be designed with the future in mind, allowing organizations to adapt or upgrade their systems as their testing needs evolve.

Conclusion

The significance of custom electronic tensile testers cannot be overstated in today’s competitive landscape. By offering precision, tailored capabilities, and enhanced efficiency, these testing machines play a crucial role in advancing material science and ensuring product quality across various industries. As technology progresses, the evolution of customized solutions promises to further enhance the reliability and accuracy of tensile testing, paving the way for innovations that can reshape various sectors. Investing in a custom electronic tensile tester is not merely an option; it is a strategic imperative for organizations aiming to stay ahead in the material testing arena.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy