Bespoke Electronic Tensile Testing Equipment for Accurate Material Strength Measurement

The Evolution and Importance of Custom Electronic Tensile Testing Machines

In the realm of material science and engineering, understanding the properties of materials is paramount. Tensile testing is one of the most widely used methods to evaluate the mechanical properties of various materials, including metals, plastics, and composites. With advancements in technology, the demand for precision and customization has led to the development of custom electronic tensile testing machines. These machines not only enhance testing accuracy but also significantly improve efficiency and adaptability in diverse testing environments.

Understanding Tensile Testing

Tensile testing, also known as tension testing, involves the application of a controlled tensile load to a sample material until it reaches its yield point and ultimately fractures. The results of these tests provide critical data, including yield strength, ultimate tensile strength, elongation, and reduction of area. Such mechanical properties are vital for engineers and scientists in material selection, quality assurance, and research and development.

The Rise of Electronic Tensile Testing Machines

Traditional tensile testing machines were largely mechanical, offering limited capabilities and often requiring manual intervention. However, the evolution of electronic tensile testing machines has revolutionized the field. These machines are equipped with electronic sensors and advanced software that allow for real-time monitoring and data collection, resulting in more accurate and reliable results.

The transition from mechanical to electronic systems has enabled the automation of testing processes, reducing human error and enhancing reproducibility. Moreover, electronic machines can run various test protocols, allowing for greater versatility in material testing. From simple material characterization to complex stress-strain analysis, electronic tensile testing machines can accommodate a wide range of applications.

The Customization Factor

One of the standout features of modern electronic tensile testing machines is their ability to be customized to meet specific testing requirements

. Custom electronic tensile testing machines can be designed to tailor their capabilities to the unique characteristics of the materials being tested, as well as the specific standards required by different industries.Customization can encompass several aspects

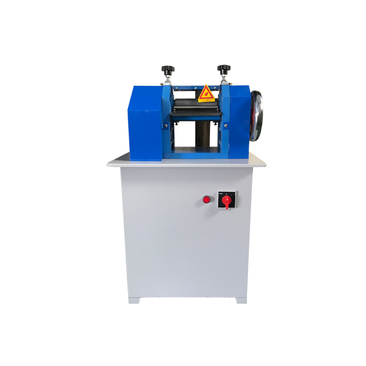

custom electronic tensile testing machine

1. Load Capacity Depending on the material type, the required load capacity can vary significantly. Custom machines can be designed to handle very high loads for robust materials or lower loads for more delicate materials.

2. Testing Speed Some materials require high-speed testing, while others may need a slower application of force to accurately capture their properties. Custom machines can be programmed to adjust testing speed dynamically.

3. Environmental Conditions Certain materials need to be tested under specific environmental conditions, such as extreme temperatures or humidity levels. Custom machines can be equipped with environmental chambers to simulate these conditions effectively.

4. Data Acquisition Systems The choice of data acquisition system can greatly influence the analysis of test results. Custom systems allow for integration with advanced software that can analyze data in real-time, providing insights that can lead to innovative research and development.

5. Sample Preparation Different materials and testing standards may require unique sample shapes and sizes. Custom machines can be designed to accommodate a variety of sample formats, ensuring compliance with specific testing protocols.

Applications Across Industries

The applications for custom electronic tensile testing machines are vast and varied. In aerospace, the reliability of materials under stress is crucial for safety. The automotive industry relies on these tests to ensure that components can withstand significant forces and impacts. In the construction and civil engineering sectors, tensile testing is essential for evaluating the strength of materials used in structures.

Moreover, the biomedical field is increasingly utilizing tensile testing to assess the properties of biomaterials and implants. This diversity underscores the importance of tailored solutions that meet distinct industry requirements.

Conclusion

Custom electronic tensile testing machines represent a significant advancement in material testing technology. Their ability to be tailored to specific needs ensures that engineers and researchers can obtain precise and reliable data, which is crucial in today’s rapidly evolving materials landscape. As industries continue to innovate and push the boundaries of material performance, the demand for such customized solutions will only grow. By investing in state-of-the-art electronic tensile testing machines, companies can ensure not only quality assurance but also pave the way for future developments in material science.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy