Custom Flame Resistance Testing Solutions for Various Applications and Industries

Custom Fire Resistance Tester Ensuring Safety Through Precision

In an age where safety standards play a crucial role in industrial operations and construction practices, ensuring materials can withstand extreme conditions is more important than ever. One of the key elements in assessing materials' reliability in the presence of fire is the fire resistance tester. This article will delve into the significance of custom fire resistance testers, how they work, and their applications in various industries.

Understanding Fire Resistance Testing

Fire resistance testing is a procedure that evaluates how well a material or assembly can withstand the effects of fire, including heat, flame, and smoke. The goal is to determine the performance of materials under fire exposure, ensuring adequate safety for occupants and conformity with regulations.

Custom fire resistance testers are specifically designed to meet the unique requirements of different materials and industries. Unlike standard testing equipment, custom models can be tailored to provide precise conditions that reflect real-world scenarios, thereby yielding more relevant results.

The Importance of Customization

The primary advantage of a custom fire resistance tester lies in its ability to be tailored to specific materials and conditions. Fire performance is not a one-size-fits-all proposition; different materials react differently under fire exposure. For instance, a tester designed primarily for wood may not provide accurate results for metal or composite materials.

Custom fire resistance testers can incorporate various parameters such as temperature ranges, exposure duration, and different fire scenarios, allowing for an accurate and comprehensive evaluation. This customization ensures compliance with relevant standards like ASTM E119, ISO 834, or UL 263, which specify the conditions and methods for fire resistance testing.

Design and Features

A typical custom fire resistance tester includes several critical components designed to accurately simulate fire conditions

. These may include1. Heating Elements These elements generate the high temperatures typically experienced during a fire. Custom systems can be designed to reach specific temperature profiles tailored to the material being tested.

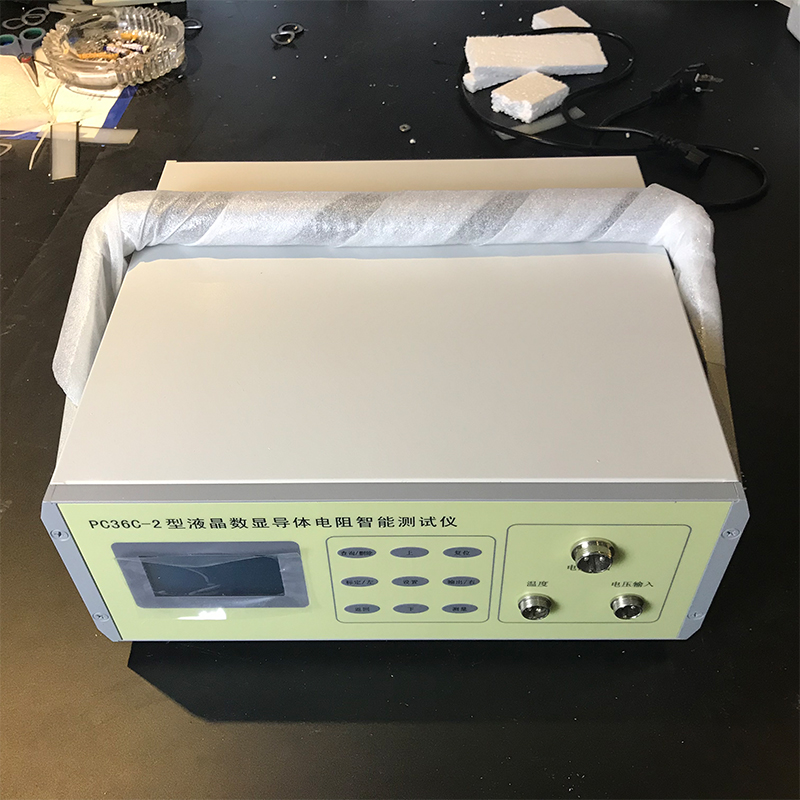

custom fire resistance tester

2. Data Acquisition Systems Advanced sensors and software collect data during the testing process. This can include temperature readings, structural integrity assessments, and smoke production analysis, which helps in determining fire performance accurately.

3. Control Systems The ability to control the testing environment is critical. Custom testers often come equipped with sophisticated control systems that can adjust variables such as temperature and time, allowing for precise test conditions.

4. User Interface A user-friendly interface can streamline the testing process, enabling operators to set parameters easily and monitor tests in real-time.

Applications Across Industries

Custom fire resistance testers find applications in various industries, including construction, aerospace, automotive, and manufacturing. For instance

- Construction and Building Materials Testing materials such as insulation, drywall, and fire-resistant coatings ensures compliance with building codes and safety regulations. - Aerospace Materials used in aircraft must withstand extreme heat and fire. Custom testers evaluate the effectiveness of these materials, ensuring passenger safety.

- Automotive With increasing concerns about vehicle safety during accidents, automakers use custom fire resistance testing to evaluate interior materials and components for their fire performance.

- Manufacturing In producing goods ranging from textiles to electronic devices, manufacturers need to ensure that their products can effectively resist fire hazards.

Conclusion

In conclusion, custom fire resistance testers are essential tools that provide critical insights into material performance under fire conditions. By delivering tailored testing protocols that align with the unique specifications of different materials, these testers play a pivotal role in promoting safety across industries. As fire safety regulations continue to evolve, the importance of precise and customized testing solutions will only heighten, making custom fire resistance testers invaluable in safeguarding lives and property. Through innovation and precision, these specialized testers serve as the frontline defenders against the unpredictable nature of fire, ensuring a safer future for all.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy