Testing Equipment for Custom Flexible Cable Solutions and Applications

Custom Flexible Cables Testing Equipment

In the modern world, the significance of reliable electrical connections cannot be overstated. As industries evolve, the demand for custom flexible cables has surged due to their adaptability in various applications, especially where space constraints and movement are critical. To ensure the performance and safety of these cables, robust testing equipment is paramount. This article delves into the key aspects of custom flexible cables testing equipment, its importance, and its application across different sectors.

Understanding Custom Flexible Cables

Flexible cables are designed to withstand bending, twisting, and other mechanical stresses. They are commonly used in robotics, manufacturing, automotive, and even consumer electronics. Custom flexible cables are tailored to meet specific operational requirements, such as varying lengths, conductivity, insulation types, and environmental resistance. However, with customizations comes the challenge of ensuring that these cables perform adequately in their intended applications.

The Role of Testing Equipment

Testing equipment for custom flexible cables serves as a critical line of defense against potential failures. The main objective of such equipment is to validate several performance characteristics, including electrical conductivity, insulation integrity, and mechanical resilience. Here, we explore the various types of tests conducted on flexible cables

1. Electrical Testing This includes tests for continuity and resistance to ensure that cables can carry current efficiently without overheating. Equipment such as multimeters and insulation resistance testers are commonly used for these purposes.

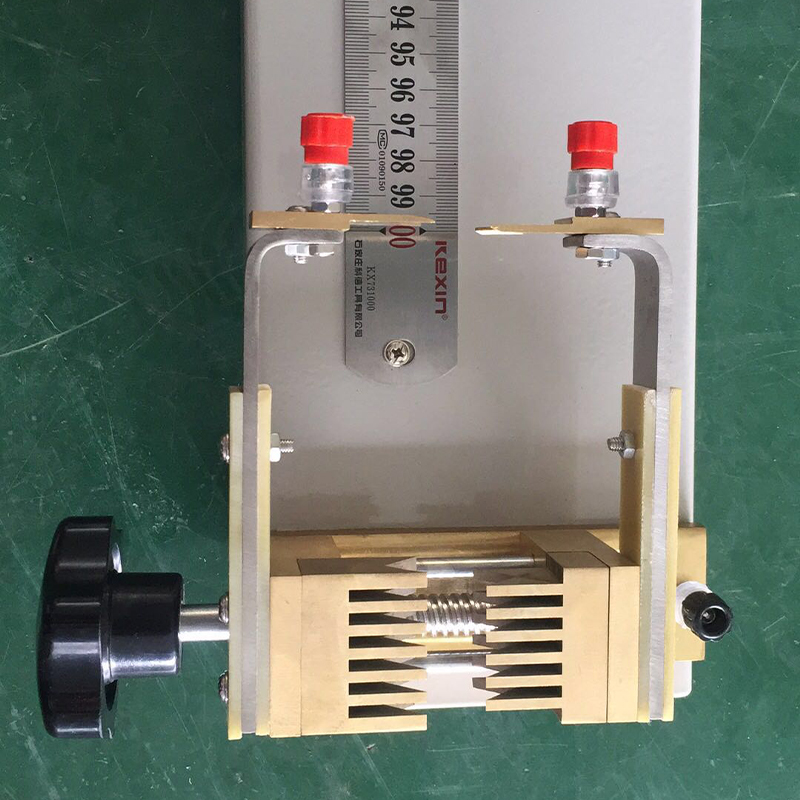

2. Mechanical Testing Given the flexible nature of these cables, it is essential to assess their strength and durability. Tests often include tensile strength assessments and flexural life tests to evaluate how well cables withstand repeated bending over time.

3. Environmental Testing Flexible cables often operate in harsh environments, subject to extreme temperatures, moisture, or corrosive substances. Climate chambers and environmental test rigs are utilized to simulate these conditions and verify the cables' longevity and performance under stress.

custom flexible cables testing equipment

4. Flame Resistance Testing For certain applications, especially in the aerospace and automotive sectors, flame resistance is a critical requirement. Specialized equipment is used to conduct flammability tests to ensure compliance with safety standards.

Advantages of Using Advanced Testing Equipment

Employing state-of-the-art testing equipment provides several advantages

- Precision Advanced digital tools provide accurate measurements, ensuring that any deviations from standards are promptly identified.

- Efficiency Modern testing equipment often allows for automated processes, significantly reducing the time required to conduct tests and thereby accelerating production timelines.

- Data Analysis The capability to collect and analyze testing data allows manufacturers to refine their cable designs based on performance feedback, leading to continuous improvement.

- Compliance Adhering to industry regulations is crucial. Testing equipment ensures that custom flexible cables meet local and international standards, guaranteeing safety and reliability.

Conclusion

In conclusion, the significance of custom flexible cables in contemporary technology cannot be underestimated, and neither can the importance of specialized testing equipment. By ensuring the reliability and performance of these cables through rigorous testing, manufacturers can provide end-users with the confidence they need to utilize flexible cabling solutions in their applications. As technology continues to advance, the development of even more sophisticated testing equipment will undoubtedly play a vital role in the ongoing evolution of custom flexible cables and their applications across diverse industries.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy