Custom High Insulation Resistance Testing Solutions for Enhanced Electrical Safety

Custom High Insulation Resistance Testing A Comprehensive Overview

In the realm of electrical engineering, insulation resistance testing plays a critical role in ensuring the reliability and safety of electrical installations. Among the various categories of insulation tests, custom high insulation resistance tests stand out for their specialized applications and significance in preventing electrical failures. This article delves into the concept, methodology, benefits, and applications of custom high insulation resistance testing.

Understanding Insulation Resistance Testing

Insulation resistance testing is a procedure designed to assess the integrity of electrical insulation. The test essentially measures the resistance of an insulator to the flow of electrical current, ensuring that the insulation is functioning properly and is capable of preventing leakage currents that could lead to equipment damage or electrical hazards. Standard testing often utilizes resistance values, typically measured in megohms (MΩ), to evaluate the insulation of cables, transformers, and motors.

The Importance of Custom High Insulation Resistance Testing

While standard insulation resistance tests are vital for routine inspections, certain applications require a more tailored approach—this is where custom high insulation resistance testing comes into play. Custom tests are specifically designed to meet the unique needs and conditions of particular systems or environments. For instance, high insulation resistance tests might be necessary for systems operating in harsh conditions or for equipment with significant insulation challenges.

High insulation resistance testing is especially relevant in sectors such as power generation, transmission, and manufacturing, where even minor insulation failures can lead to catastrophic consequences, including equipment damage, downtime, and safety hazards. Custom tests enable engineers to simulate real-world conditions and better understand how different elements of an electrical system interact under stress.

Methodology of Custom High Insulation Resistance Testing

Implementing a custom high insulation resistance test involves a systematic approach that incorporates several key steps

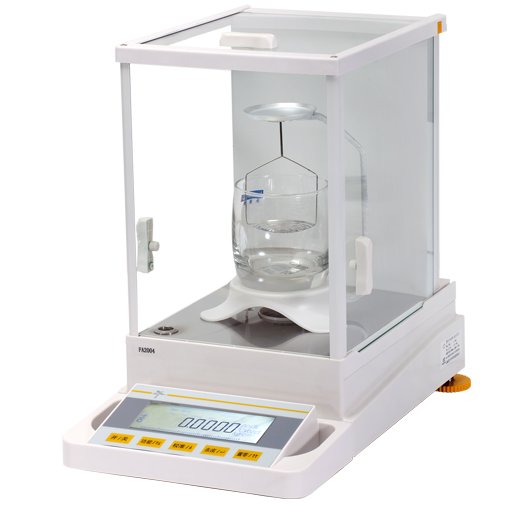

custom high insulation resistance test

1. Preparation Before testing, the engineer gathers all relevant data about the equipment and the operating environment. This includes the type of materials used, the ambient conditions, and any past insulation resistance test results.

2. Selection of Parameters The next step includes selecting test parameters, such as test voltage levels, duration, and specific methods that align with the goals of the test. For high insulation resistance testing, higher test voltages (often in the range of 500V to 5kV) may be employed to stress the insulation and reveal any weaknesses.

3. Conducting the Test The actual testing is performed using specialized equipment designed to deliver the selected voltage while simultaneously measuring the resistance values. During this phase, it’s essential to ensure that safety protocols are strictly followed to protect both personnel and equipment.

4. Data Analysis Once the testing is completed, the data collected is analyzed to determine the insulation resistance levels. Engineers will interpret the results against industry standards, looking for signs of deterioration or potential points of failure.

5. Reporting and Recommendations Finally, a comprehensive report is compiled, outlining the findings of the test along with any recommendations for mitigation or corrective actions as necessary.

Benefits of Custom High Insulation Resistance Testing

The advantages of custom high insulation resistance testing are manifold. First and foremost, it enhances electrical safety and reduces the risk of failures that can result in costly repairs or accidents. Furthermore, it allows businesses to establish a proactive maintenance strategy, fostering a culture of reliability and operational efficiency. Additionally, customized tests can lead to a better understanding of insulation behavior over time, informing better design and selection of materials for future installations.

Conclusion

In conclusion, custom high insulation resistance testing represents an essential component of contemporary electrical engineering practices. By catering to the unique requirements of diverse applications, this testing methodology not only ensures safety and reliability but also empowers organizations to make informed decisions about their electrical infrastructures. As technology advances, the need for increasingly sophisticated testing strategies will continue to grow, emphasizing the importance of tailored solutions in the ever-evolving electrical landscape.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy