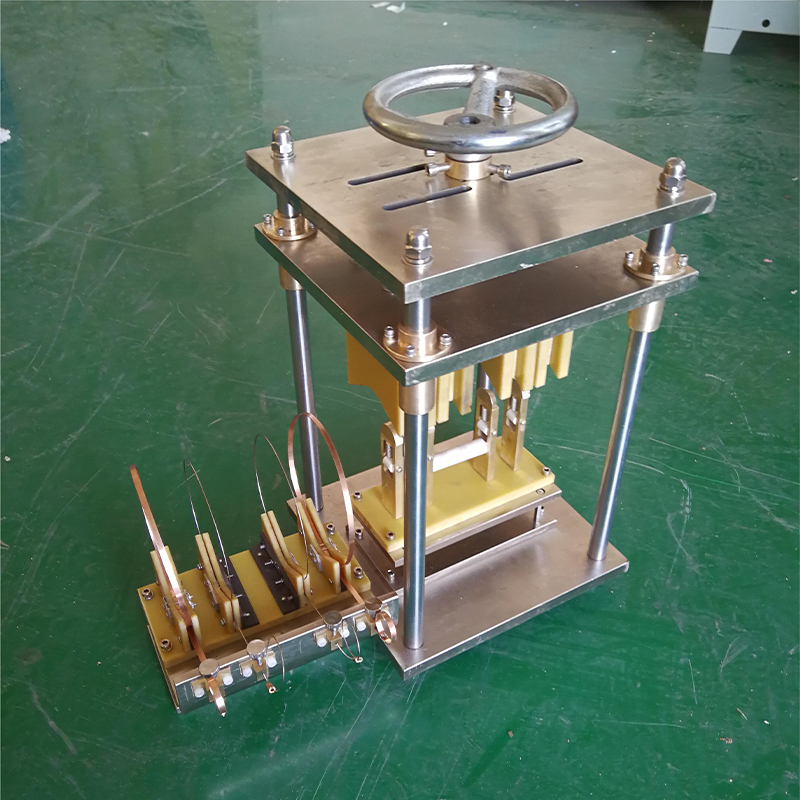

custom high insulation resistance tester

Custom High Insulation Resistance Tester Ensuring Safety and Reliability

In an era where electrical systems power homes, industries, and critical infrastructures, ensuring their reliability and safety has never been more paramount. Among the myriad of tools available for maintaining electrical safety, the high insulation resistance tester stands out as a vital instrument. This device is engineered to assess the insulation integrity of electrical systems, identifying potential faults before they escalate into catastrophic failures. In particular, custom high insulation resistance testers are tailored to meet the unique requirements of various industries, enhancing safety and operational efficiency.

Understanding Insulation Resistance Testing

Insulation is essential for the safe operation of electrical equipment. It prevents unwanted current leakage, protects against electric shocks, and enhances overall system reliability. Over time, insulation materials may degrade due to environmental factors, mechanical stress, or aging. The primary function of an insulation resistance tester is to measure the resistance of the insulation to direct current (DC). A high resistance value typically indicates good insulation, while a low resistance value may suggest deterioration or failure.

Standard insulation resistance testers can effectively measure insulation in various applications, but the need for custom solutions arises from specific operational demands. This is where custom high insulation resistance testers come into play. These devices can be tailored to meet different voltage requirements, environmental conditions, and unique user specifications.

Key Features of Custom High Insulation Resistance Testers

1. Tailored Voltage Ranges Different industries have varying insulation testing voltage requirements based on the equipment used. Custom testers can be designed to offer a wide range of voltage options, ensuring accurate measurements regardless of the application.

2. Enhanced Accuracy and Sensitivity With advancements in technology, modern custom high insulation resistance testers provide exceptional accuracy and sensitivity. They can detect even the slightest changes in insulation resistance, allowing for early detection of potential issues.

3. Durability and Environmental Resistance Many applications require equipment that can withstand harsh environments. Custom testers can be designed with rugged casings and weather-resistant features, making them suitable for outdoor use and extreme conditions.

custom high insulation resistance tester

4. User-Friendly Interfaces Modern test equipment should be easy to use, even for technicians with varying levels of expertise. Custom testers often come with intuitive interfaces, clear displays, and simple controls that enhance user experience and facilitate training.

5. Data Logging and Connectivity Options Today’s insulation resistance testers often feature data logging and transmission capabilities. Custom models can be equipped with Bluetooth or Wi-Fi for easy sharing of test results, enabling prompt analysis and record-keeping.

6. Compliance with Industry Standards Ensuring that testing equipment meets industry standards and regulations is vital. Custom testers can be designed to comply with specific standards pertinent to various industries, such as IEEE, IEC, or ASTM.

The Importance of Regular Insulation Testing

Regular insulation testing is critical for several reasons. For one, it helps to identify deteriorating insulation before it leads to equipment failures, downtime, or costly repairs. It also contributes to the safety of personnel working around electrical systems, minimizing the risk of electric shocks. Additionally, conducting routine tests can enhance the lifespan of electrical equipment, reducing the total cost of ownership.

Industries Benefiting from Custom High Insulation Resistance Testers

Several industries can benefit from using custom high insulation resistance testers. For instance, the power generation and distribution sector relies on these tools to maintain the safety and reliability of transformers, generators, and power lines. Manufacturing facilities utilize insulation testing to assess the integrity of motors, drives, and other electrical components. Furthermore, the renewable energy sector, particularly wind and solar power, requires rigorous testing of insulation in turbines and solar panels to ensure optimal performance.

Conclusion

In conclusion, a custom high insulation resistance tester is an invaluable asset in the quest for electrical safety and performance. By tailoring these testers to meet specific industry needs, organizations can significantly enhance their operational efficiency and safety measures. As electrical systems continue to evolve and expand, the importance of accurate and reliable insulation testing will undoubtedly remain a top priority for ensuring the safety of personnel and the reliability of equipment. Investing in a custom solution today is a proactive step toward a secure and efficient electrical future.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy