Understanding Custom IEC 60332 Standards for Cable Flame Test Applications

Understanding Custom IEC 60332 A Guide to Flame Retardant Testing for Cables

In today's world, where safety standards are paramount, the importance of flame retardant testing for electrical cables cannot be overstated. The IEC 60332 standard, developed by the International Electrotechnical Commission (IEC), provides guidelines for assessing the vertical flame propagation of insulated cables. Custom IEC 60332 testing involves adapting the standard to meet specific requirements or to fit particular cable designs, ensuring that products not only comply with international safety regulations but also cater to unique industry needs.

What is IEC 60332?

IEC 60332 is a standard that outlines the methods for testing the flame retardance of electrical cables. Its primary objective is to evaluate how well a cable can withstand a fire and prevent the spread of flames along its surface. This is particularly critical in environments where electrical installations could pose significant fire hazards, such as in transportation vehicles, industrial settings, and buildings.

The standard specifies different test methods, primarily categorized into two parts IEC 60332-1, which focuses on the vertical flame spread on single insulated wires, and IEC 60332-3, which assesses the flame propagation on bundled cables. These tests help manufacturers ensure that their products will perform safely when subjected to fire conditions.

The Need for Custom IEC 60332 Testing

While standard compliance is crucial, many manufacturers may find that their products have unique characteristics or are used in specialized environments. As a result, custom IEC 60332 testing is increasingly gaining traction. Custom testing may involve modifications to the test setup, evaluation criteria, or even the formulation of the cables themselves to better represent real-world conditions.

For example, cables used in marine applications must endure harsher conditions than typical indoor cables, including higher humidity and saltwater exposure. Custom IEC 60332 testing can simulate these environmental factors to provide a more accurate assessment of how the cable will react in actual conditions.

Advantages of Custom IEC 60332 Testing

1. Tailored Solutions Custom testing allows manufacturers to design tests that align closely with the specific applications and environments in which their cables will be used. This leads to more reliable results and better product performance.

2. Increased Safety By addressing unique risks associated with specific cable applications, custom testing enhances user safety. Manufacturers can identify potential vulnerabilities in their products and make necessary adjustments.

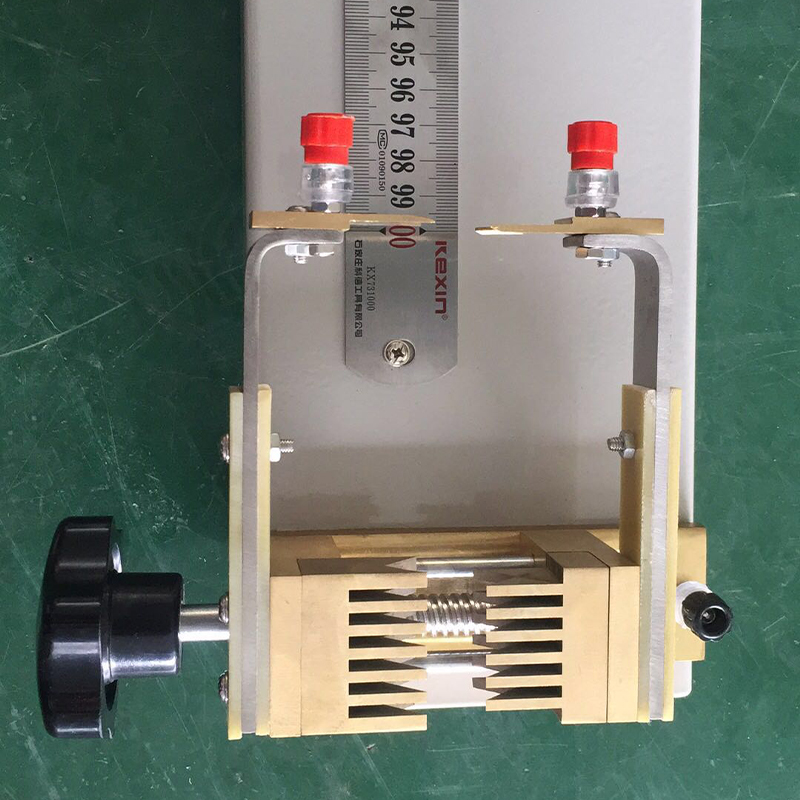

custom iec60332

3. Competitive Edge In a market where safety is a critical concern, having cables that meet enhanced flame retardance standards can give manufacturers a significant advantage. It allows them to market their products as superior in safety and reliability.

4. Regulatory Compliance Custom IEC 60332 testing ensures that manufacturers meet not only local regulations but also international standards. This can facilitate easier entry into foreign markets and bolster consumer confidence.

Implementing Custom IEC 60332 Testing

To implement custom IEC 60332 testing, companies typically follow a series of steps

- Consultation with Standards Experts Engage with professionals who understand the IEC standards and can help adapt them to your specific needs.

- Defining Test Parameters Identify the unique conditions that the cables will be exposed to and tailor the testing parameters accordingly.

- Testing and Evaluation Conduct the tests in a controlled environment, ensuring that all variables are accounted for. Use the findings to modify cable designs or materials as necessary.

- Documentation and Certification After testing, thoroughly document the results and seek certification from recognized bodies to validate compliance.

Conclusion

Custom IEC 60332 testing is a crucial aspect of ensuring that electrical cables are safe for use in various applications. By adapting the IEC 60332 standard to fit particular needs, manufacturers can provide added assurance of their products’ performance under fire conditions. The approach not only enhances the safety and reliability of cables but also supports businesses in competing effectively in an increasingly safety-conscious market. As industries evolve, ongoing innovation in testing methods will continue to play a pivotal role in safeguarding lives and property.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy