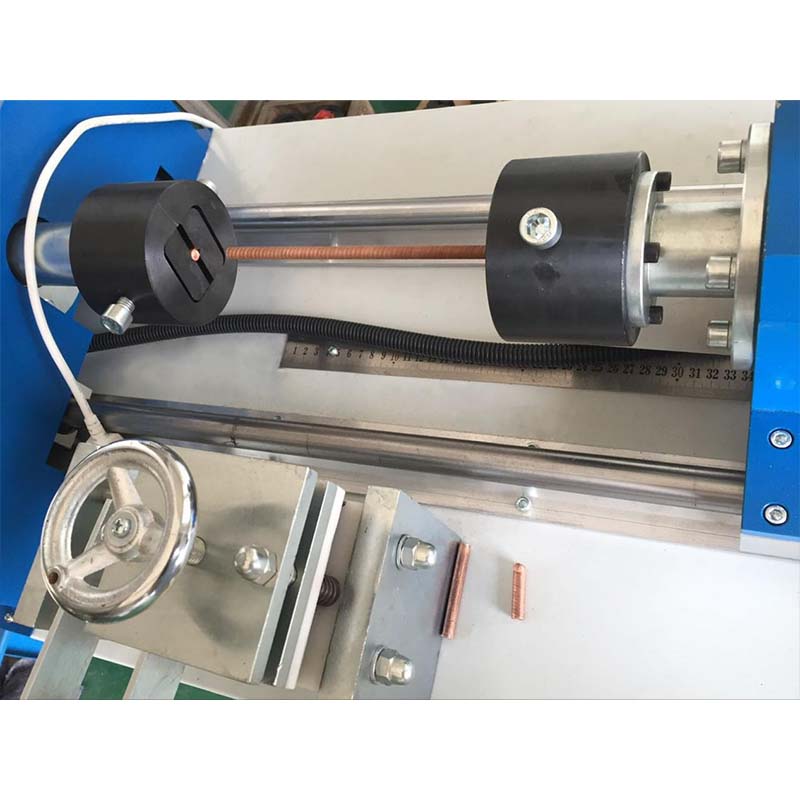

custom manual tensile tester

Custom Manual Tensile Tester An Essential Tool for Material Testing

In today's fast-paced industrial environment, quality assurance and material testing play a pivotal role in ensuring the reliability and performance of products. Among the various instruments used for testing materials, the custom manual tensile tester stands out as a vital tool. This device is specifically designed to measure the tensile strength, elongation, and other mechanical properties of materials, providing crucial insights for manufacturers and engineers.

What is a Custom Manual Tensile Tester?

A custom manual tensile tester is a specialized piece of equipment that allows users to perform tensile tests on various materials, including metals, plastics, textiles, and composites. Unlike automated testing machines, a manual tensile tester requires human operation, giving users complete control over the testing process. This customization allows manufacturers to tailor the device to their specific needs, accommodating different material types, sizes, and testing requirements.

Key Features and Benefits

One of the primary advantages of a custom manual tensile tester is its versatility

. These devices can be designed to handle a wide range of samples, from small filaments to larger sheets of material. This flexibility is essential for laboratories and production facilities working with diverse materials and ensuring they meet industry standards.Another significant benefit is the cost-effectiveness of manual testers. While automated machines can offer increased efficiency, they often come with a hefty price tag. Custom manual tensile testers provide an affordable alternative without sacrificing essential testing capabilities. This makes them an attractive option for small to medium-sized businesses seeking to conduct reliable material testing without excessive expenditure.

User-Friendly Design

custom manual tensile tester

Custom manual tensile testers are typically designed with user ergonomics in mind. They feature intuitive controls and clear display interfaces that enable users to conduct tests with minimal training. The manual operation allows users to adjust testing parameters on-the-fly, ensuring that each test can be tailored to the material's characteristics.

Moreover, these testers often come with built-in safety features to protect both the user and the equipment. Proper training and adherence to safety protocols are essential, but the design of a well-made manual tensile tester can significantly mitigate risks during testing.

Applications in Various Industries

The applications of custom manual tensile testers are vast. In the construction industry, they are used to assess the tensile strength of materials like concrete and metals, ensuring structural integrity. In the textile industry, these testers evaluate the strength and elasticity of fabrics, contributing to quality control in the production of clothing and upholstery.

Furthermore, the automotive and aerospace sectors utilize tensile testing to verify the mechanical properties of components and materials used in vehicles and aircraft. By identifying weaknesses or inconsistencies, manufacturers can address potential failures before products reach the market.

Conclusion

In conclusion, the custom manual tensile tester is an indispensable tool in material testing, offering flexibility, cost-effectiveness, and user-friendly operation. Its ability to deliver accurate and reliable results makes it a favorite among industries that prioritize quality assurance. As the demand for high-quality materials escalates, the significance of manual tensile testers only continues to grow, paving the way for innovation and excellence in material science and engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy