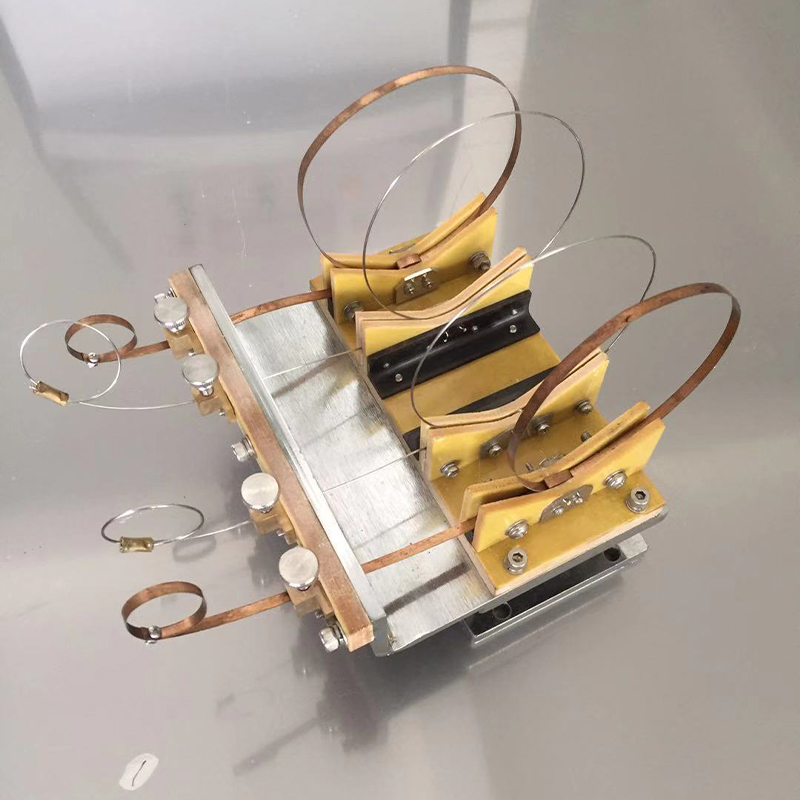

custom optical measurement machine

Custom Optical Measurement Machines Revolutionizing Precision Measurement

In the fast-paced world of manufacturing and quality assurance, precision is paramount. As industries strive for excellence, the need for advanced measurement technologies becomes evident. One such innovation is the custom optical measurement machine, a sophisticated tool designed to meet the specific demands of various sectors, including aerospace, automotive, electronics, and medical devices. These measurement machines harness the principles of optics to deliver unparalleled accuracy and efficiency in measurement processes.

Understanding Optical Measurement Technology

Optical measurement technology relies on light to capture and analyze the dimensions and features of an object. Unlike traditional contact measurement methods that can alter the object being measured, optical systems utilize non-contact techniques. This capability is particularly advantageous for delicate materials or intricate geometries where physical contact might introduce errors or damage.

Optical measurement machines typically incorporate advanced components such as high-resolution cameras, lasers, and sophisticated software algorithms. These machines can measure features down to the micrometer scale, making them suitable for a wide array of applications. From verifying the complexity of geometric shapes to inspecting surface finishes, optical measurement provides versatile solutions.

The Case for Customization

One of the most significant advantages of optical measurement machines is their ability to be customized. Different industries come with unique challenges and specifications that off-the-shelf measurement systems may not adequately address. By tailoring optical measurement machines to meet specific requirements, businesses can achieve optimal efficiency and accuracy.

Customization can encompass various aspects, including

1. Measurement Range Different applications require different measurement ranges. Custom optical measurement machines can be designed to handle specific sizes, whether it’s measuring small electronic components or large automotive parts.

2. Resolution The level of detail required can vary significantly across industries. A custom machine can be equipped with optics and sensors suited to deliver the necessary resolution for the task at hand.

custom optical measurement machine

3. Software Integration Advanced optical measurements often require complex data analysis. Custom software can be developed to integrate seamlessly with existing systems, allowing for real-time data processing and reporting.

4. Specialized Fixtures The physical setup of measurement systems can be critical. Custom fixtures can be designed to securely hold parts in place, ensuring accuracy while accommodating the unique shapes and sizes of different components.

Advantages of Custom Optical Measurement Machines

The implementation of custom optical measurement machines brings several key benefits to organizations

- Increased Efficiency By minimizing measurement time and improving throughput, customized systems streamline production processes. This efficiency can lead to faster turnaround times and reduced labor costs.

- Enhanced Accuracy Custom solutions are designed with specific tolerances and requirements in mind. This precision reduces the likelihood of errors and rework, resulting in higher-quality products.

- Flexibility As industries evolve, so do their measurement requirements. Custom optical measurement machines can be adapted or upgraded to meet changing production needs, ensuring longevity and return on investment.

- Improved Competitive Edge Companies that invest in tailored measurement solutions can differentiate themselves in the market. By guaranteeing the quality and reliability of their products, they can build stronger relationships with clients and partners.

Conclusion

The development and adoption of custom optical measurement machines represent a significant advancement in the field of precision measurement. By leveraging the power of optics, these machines offer unprecedented accuracy, efficiency, and customization tailored to industry-specific requirements. As manufacturing processes continue to become more intricate, the demand for such specialized measurement systems will likely grow. Investing in custom optical measurement solutions not only enhances product quality but also positions businesses at the forefront of technological innovation. In a world where precision is critical, custom optical measurement machines are poised to revolutionize how industries approach measurement challenges.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy