Custom Optical Profile Projector for Precision Measurement and Quality Control Solutions

Custom Optical Profile Projector Enhancing Precision in Measurement

In the realm of precision engineering, the need for accurate measurements and visual inspections is paramount. One of the tools that stand out in this field is the optical profile projector. This instrument combines optical properties with advanced technology to provide a reliable solution for gauging the dimensions and contours of various components. A custom optical profile projector takes this functionality a step further, allowing for tailored solutions that meet specific industrial demands.

What is an Optical Profile Projector?

An optical profile projector is an advanced measurement tool that projects the silhouette of a workpiece onto a screen, allowing operators to analyze its geometry with precision. This tool employs a light source and an optical lens system to magnify the profile of an object, enabling users to measure angles, radii, and other critical dimensions accurately. With a dedicated optical profile projector, operators can achieve high levels of detail, making it an invaluable asset in quality control processes and precision engineering applications.

Benefits of Customization

The importance of a custom optical profile projector cannot be overstated. Each industry has unique requirements based on the materials they work with, the complexities of the components, and the specific measurements needed. By creating a custom profile projector, manufacturers can address particular operational challenges. Here are some key benefits of investing in a customized solution

1. Tailored Features Custom optical profile projectors can be designed with specific measurement features, such as advanced optics or specialized software for data analysis. This customization enables businesses to streamline their measurement processes to accommodate the distinct shapes and sizes of their components.

2. Increased Accuracy With bespoke calibration and adjustment options, a custom projector can provide enhanced accuracy that matches the specific tolerances required by the industry. This leads to improved product quality and decreased rejection rates during inspections.

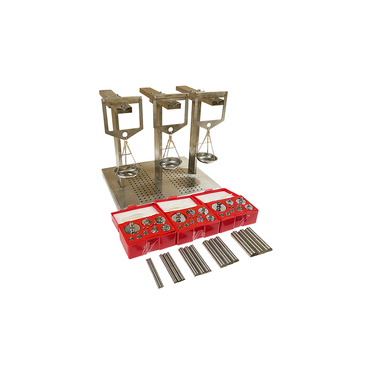

custom optical profile projector

3. User-Friendly Interface Customization can include the integration of user-friendly software interfaces that simplify operation and data logging. Operators can quickly familiarize themselves with these systems, minimizing training time and boosting productivity.

4. Integration with Existing Systems A tailored optical profile projector can be designed to seamlessly integrate with an organization’s existing measurement and quality control systems. This compatibility ensures that businesses can enhance their measurement capabilities without overhauling their entire operation.

5. Adaptability Different projects may require varying specifications. A custom projector can be engineered to be adaptable, allowing for configuration changes without significant downtime. This flexibility is essential for manufacturers who work on multiple projects with different requirements.

Applications Across Industries

Custom optical profile projectors find applications in numerous industries, including automotive, aerospace, medical device manufacturing, and electronics. In the automotive sector, precision measurements are critical for component fit and performance, making reliable optical inspection tools indispensable. Similarly, in aerospace, where safety and regulations are stringent, custom optical profile projectors ensure that all components meet the necessary standards.

In the medical device industry, precision is crucial for the functionality and safety of devices. Custom projectors allow for intricate measurements of complex geometries, ensuring that each part meets exacting specifications. Moreover, as technology advances, custom optical profile projectors can evolve with new capabilities, delivering even more precise solutions tailored to cutting-edge industry needs.

Conclusion

As industries continue to advance in complexity and precision, the role of measurement tools becomes increasingly vital. A custom optical profile projector is not merely an instrument; it is a critical component of a manufacturer’s quality assurance framework. By investing in customization, companies can unlock greater accuracy, efficiency, and adaptability in their processes. Ultimately, this leads to enhanced product quality and ensures compliance with industry standards, positioning businesses for success in a competitive landscape. Whether for small-scale applications or large-scale production, the advantages of a custom optical profile projector are evident, affirming its place as an essential tool in modern engineering practices.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy