Designing a Tailored Resistance Fixture for Enhanced Testing Solutions

Custom Resistance Fixture Enhancing Precision and Efficiency in Testing

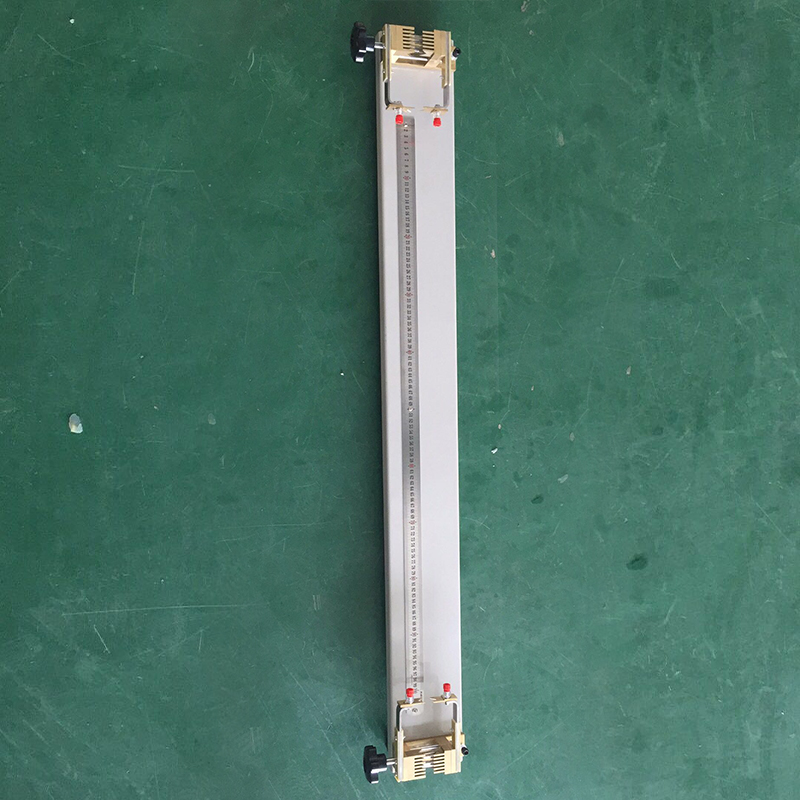

In the realm of materials testing and quality assurance, a custom resistance fixture plays a crucial role in ensuring the accuracy and reliability of results. As industries continue to evolve and demand higher precision, the need for personalized testing equipment becomes increasingly evident. This article delves into the significance of custom resistance fixtures, their applications, and the advantages they offer to various sectors.

Understanding Resistance Fixtures

A resistance fixture is an essential tool used in electrical testing to measure the resistance of materials, components, or systems. It provides a controlled environment where specific parameters can be altered to evaluate the subject's performance under various conditions. Custom resistance fixtures are specifically designed to meet the unique requirements of different tests, accommodating the dimensions, shapes, and electrical characteristics of the materials being tested.

Applications of Custom Resistance Fixtures

Custom resistance fixtures find applications across several industries, including automotive, aerospace, electronics, and telecommunications. Here are some key areas where these fixtures are commonly employed

1. Electronics Testing In the electronics industry, manufacturers need to ensure that their products meet stringent safety and performance standards. Custom resistance fixtures facilitate accurate testing of circuit boards, connectors, and other electronic components by providing precise resistance measurements under controlled conditions.

2. Material Research and Development Researchers developing new materials often need to assess their electrical properties. Custom resistance fixtures allow scientists to tailor tests to specific materials, enabling them to gather comprehensive data on resistivity and other critical characteristics.

3. Aerospace Components In the aerospace sector, the reliability of components is paramount. Custom resistance fixtures are used to test critical parts, ensuring they can withstand extreme environments while maintaining their electrical properties.

4. Quality Control Many manufacturing processes involve routine testing of materials to ensure quality. Custom resistance fixtures can be integrated into production lines, providing real-time resistance measurements that help maintain product standards and reduce defects.

custom resistance fixture

Advantages of Custom Resistance Fixtures

The benefits of investing in custom resistance fixtures are manifold

1. Tailored Solutions Unlike standard fixtures, custom designs can be adapted to the exact specifications of the testing requirements. This flexibility ensures that all aspects of a test are optimized for accuracy, which can lead to more reliable data and insights.

2. Increased Efficiency Custom fixtures can streamline the testing process. By offering tailored setups that accommodate specific tests, they reduce preparation time and increase throughput, enhancing overall operational productivity.

3. Cost-Effectiveness While the initial investment in custom fixtures may be higher than off-the-shelf solutions, the long-term savings can be significant. By minimizing errors and rework, and maximizing efficiency, custom fixtures prove to be a cost-effective solution in the long run.

4. Enhanced Data Accuracy Properly designed custom fixtures eliminate variables that could compromise test results. This leads to more consistent measurements, ultimately improving the reliability of data collected during testing.

5. Support for Innovation As industries push the boundaries of technology and material science, custom resistance fixtures can evolve alongside new advancements. They can be modified or redesigned to accommodate different testing scenarios, ensuring that companies remain competitive in a rapidly changing landscape.

Conclusion

In conclusion, the importance of custom resistance fixtures cannot be overstated in the context of modern testing methodologies. Their ability to provide tailored solutions for specific testing requirements greatly enhances the reliability and efficiency of the testing process. As industries continue to demand more precise and innovative solutions, the role of these fixtures will only grow in prominence. Investing in custom resistance fixtures not only streamlines operations but also bolsters the integrity of the data collected, ensuring that products meet the highest standards of quality and performance. As technology continues to advance, the adaptability and functionality of custom fixtures will be pivotal in shaping the future of materials testing and quality assurance.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy