Custom Single Cable Fire Test Device for Efficient Safety Evaluation and Performance Assessment

Custom Single Cable Burning Tester Ensuring Safety and Compliance in Electrical Engineering

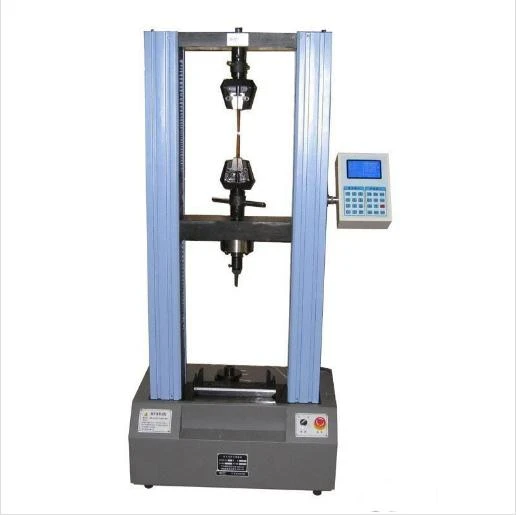

In the realm of electrical engineering, safety and reliability are paramount. With the increasing use of specialized cables in various applications, testing their fire resistance and overall durability has become essential. Among the techniques employed to assess these qualities, the Custom Single Cable Burning Tester stands out as a crucial piece of equipment that helps manufacturers and engineers ensure their products meet safety standards. This article delves into the design, functionality, and significance of custom single cable burning testers.

Understanding the Importance of Cable Testing

Cables are the veins of any electrical system, transmitting power and data across various devices and installations. However, not all cables are created equal. The materials used in manufacturing cables can significantly impact their behavior under extreme conditions. As such, it's vital to assess the fire resistance properties of these cables to prevent catastrophic failures that could lead to property damage, injury, or even loss of life.

Fire resistance testing involves exposing cables to controlled burning conditions and evaluating their performance. This includes aspects like flame propagation, smoke generation, and emissions of harmful gases. A Custom Single Cable Burning Tester is designed to facilitate such evaluations with precision and reliability.

Design Features of the Custom Single Cable Burning Tester

A custom single cable burning tester is tailored specifically to meet the requirements of various cable types and sizes. Some notable features often include

1. Adjustable Test Parameters The tester allows for the customization of burning conditions—temperature, duration, and flame type—to replicate real-world scenarios accurately.

2. Safety Mechanisms Safety is a prime concern while conducting burning tests. These testers are equipped with advanced safety features, including fire suppression systems and emergency shutdown protocols, to protect operators and the surrounding environment.

3. Monitoring and Data Collection Modern testers employ sophisticated sensors to monitor parameters during the test, such as temperature and smoke density. This data can be invaluable for future analysis and compliance with industry standards.

4. User-Friendly Interface Many testers are designed with intuitive interfaces that simplify operation, allowing engineers and technicians to set up and run tests with minimal training.

custom single cable burning tester

The Testing Process

Conducting a test using a Custom Single Cable Burning Tester typically involves the following steps

1. Preparation The cable sample is prepared according to standardized specifications, ensuring consistency and accuracy in results.

2. Setup The tester is configured for the desired test parameters, taking care to account for specific standards like IEC, UL, or ASTM as applicable.

3. Execution The burning test is conducted, during which the cable is exposed to flames for a predetermined amount of time. Observations regarding flame spread, burning duration, and smoke generation are carefully recorded.

4. Analysis Post-test analysis involves evaluating the collected data against safety standards. Results inform decisions on the efficacy of the cable materials and their adherence to fire safety regulations.

Significance in Industry

The implications of employing a custom single cable burning tester extend beyond mere compliance. For manufacturers, it significantly enhances product safety and quality assurance. By ensuring that cables have been rigorously tested for fire resistance, companies can bolster their reputation and build consumer trust. Additionally, many industries, including construction, automotive, and telecommunications, have stringent regulations requiring compliance with safety standards. Testing cables helps companies avoid costly recalls and potential legal issues that may arise from using sub-par materials.

Moreover, as new materials and technologies are developed for cable manufacturing, having a custom burning tester allows manufacturers to adapt and update their testing protocols in line with innovative designs and safety requirements.

Conclusion

In conclusion, the Custom Single Cable Burning Tester plays a vital role in safeguarding electrical systems against fire hazards. By offering precise, adaptable, and safe testing conditions, it empowers manufacturers to deliver high-quality, compliant products to the marketplace. In an ever-evolving industry, investing in reliable testing solutions is not just a regulatory obligation but a commitment to safety that benefits everyone.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy