custom smoke density chamber test

Understanding Custom Smoke Density Chamber Testing

In recent years, the importance of assessing fire safety in various materials and products has surged, leading to the development and implementation of numerous testing methodologies. One such method is the Custom Smoke Density Chamber Test, a crucial procedure that helps evaluate the smoke production characteristics of materials when exposed to fire.

What is Smoke Density Chamber Testing?

Smoke Density Chamber Testing is a controlled laboratory examination aimed at measuring the smoke emitted from burning materials. The test provides valuable data on smoke density, specific optical density, and the potential for smoke to cause visibility impairment during a fire event. This information is critical for designers, architects, and safety professionals, as it informs fire risk assessments and the overall safety of buildings and infrastructure.

The Significance of Smoke Density

Smoke density is a critical factor that can significantly affect the survivability of individuals during a fire emergency. High-density smoke can obscure visibility, hinder escape routes, and exacerbate the inhalation of toxic gases. In many cases, smoke inhalation is the leading cause of death in fire incidents, often surpassing direct exposure to flames. Therefore, understanding the smoke production characteristics of materials used in construction, furnishings, and other applications is essential for enhancing life safety.

The Custom Smoke Density Chamber

A Custom Smoke Density Chamber is specifically designed to measure the smoke produced by materials under controlled combustion conditions. The chamber is equipped with sophisticated instrumentation that can precisely monitor and record the density of smoke generated during the testing process. The design of these chambers allows for varying conditions, accommodating different types of materials, from textiles to plastics.

The test typically involves the combustion of a sample material in a controlled environment where the temperature and airflow can be adjusted. The generated smoke is drawn through optical sensors that measure how much light is absorbed by the smoke, providing a quantitative analysis of smoke density.

The Testing Procedure

custom smoke density chamber test

The testing procedure can be broken down into several critical steps

1. Sample Preparation The test begins with the preparation of representative samples of the materials to be tested. These samples must be uniform in size and weight to ensure accurate results.

2. Ignition The samples are ignited in the chamber using controlled methods, ensuring that combustion is sustained for a predetermined period.

3. Monitoring Throughout the test, various parameters are monitored, including temperature, smoke density, and time. The smoke is continuously drawn into the sensors for real-time analysis.

4. Data Analysis After the test, the data collected is analyzed to determine the specific optical density of the smoke and other related parameters. This analysis helps to assess the smoke’s potential impact on visibility and safety.

Applications of Smoke Density Testing

The findings from Custom Smoke Density Chamber Testing are instrumental across various industries. In the construction sector, building codes often require compliance with specific smoke density standards, particularly for materials used in public spaces. Additionally, manufacturers of electrical cabling, furniture, and automotive components can utilize smoke density data to improve product safety, ultimately leading to enhanced consumer confidence and regulatory compliance.

In the maritime industry, smoke density testing is crucial for ensuring that materials used on ships meet stringent international standards. Technologies like the International Maritime Organization (IMO) FTP Code outline the necessary criteria for materials used on vessels, emphasizing safety in the event of a fire at sea.

Conclusion

Custom Smoke Density Chamber Testing is an essential tool in the assessment of fire safety in various materials. By providing critical data on smoke production and density, this testing method contributes significantly to developing safer products and environments. As industries evolve and new materials are introduced, continued advancements in smoke testing methodologies will play a vital role in enhancing overall fire safety and regulatory compliance. Understanding and implementing these tests is essential for safeguarding lives and property in fire emergencies.

-

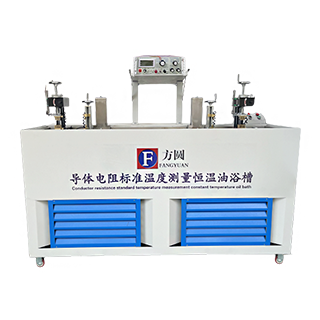

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy