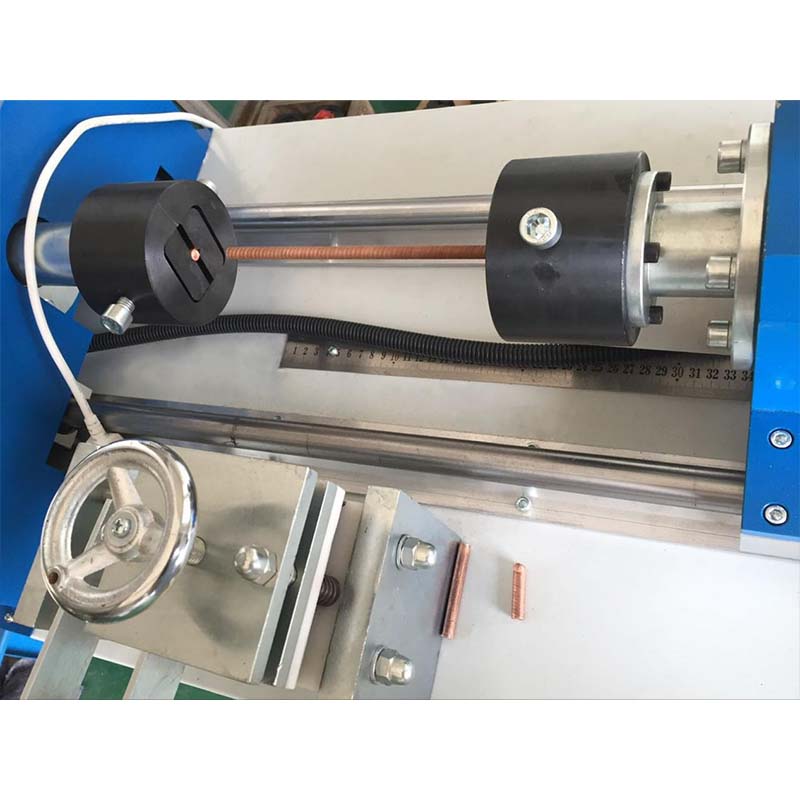

customized tensile testing machine for material strength evaluation and analysis

Custom Tensile Tester Machine Ensuring Precision in Material Testing

In today’s world, the demand for high-quality materials across various industries, including construction, manufacturing, and textiles, has never been greater. As businesses strive to ensure the durability and performance of their products, precise testing methods become crucial. One such method is the tensile test, which measures the strength and ductility of materials. A custom tensile tester machine can play an essential role in achieving accurate results tailored to specific testing needs.

A tensile tester machine, otherwise known as a universal testing machine (UTM), is designed to apply a controlled tensile force to a specimen until it deforms or breaks. The results obtained from these tests provide invaluable data on how materials will behave under stress. A custom tensile tester machine offers flexibility, allowing the integration of specialized features suited for various applications. For instance, industries that require testing of different materials, such as metals, plastics, or composites, can benefit from a machine tailored to their specific requirements.

One of the primary advantages of a custom tensile tester is its ability to accommodate unique sample sizes and shapes. Standard machines may not meet the testing specifications for specialized materials, leading to compromised results. A customized solution ensures accurate measurements by using fixtures that are specifically designed for the materials being tested. This level of precision enhances the reliability of the data gathered, enabling manufacturers to make informed decisions about material selection and design.

custom tensile tester machine

Additionally, a custom tensile tester machine can be equipped with advanced technology, such as digital load cells, precision extensometers, and automated data acquisition systems. This integration allows for real-time monitoring of the test process, improving the accuracy and speed of data collection. Comprehensive software solutions can also be added to analyze the acquired data, providing detailed insights into the material properties.

Furthermore, the design of a custom tensile tester can incorporate safety features that protect both the machine and the operator. Built-in protections against overload, emergency stop functions, and enclosed testing environments help mitigate risks associated with material testing. Ensuring a safe working environment adds an important layer of responsibility for manufacturers.

In conclusion, investing in a custom tensile tester machine is a strategic move for companies committed to quality and innovation. By providing precise testing tailored to specific materials and needs, these machines enhance the ability to produce reliable and durable products. As industries continue to evolve, so too will the technologies that support them, making the custom tensile tester an essential tool in the quest for material excellence.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy