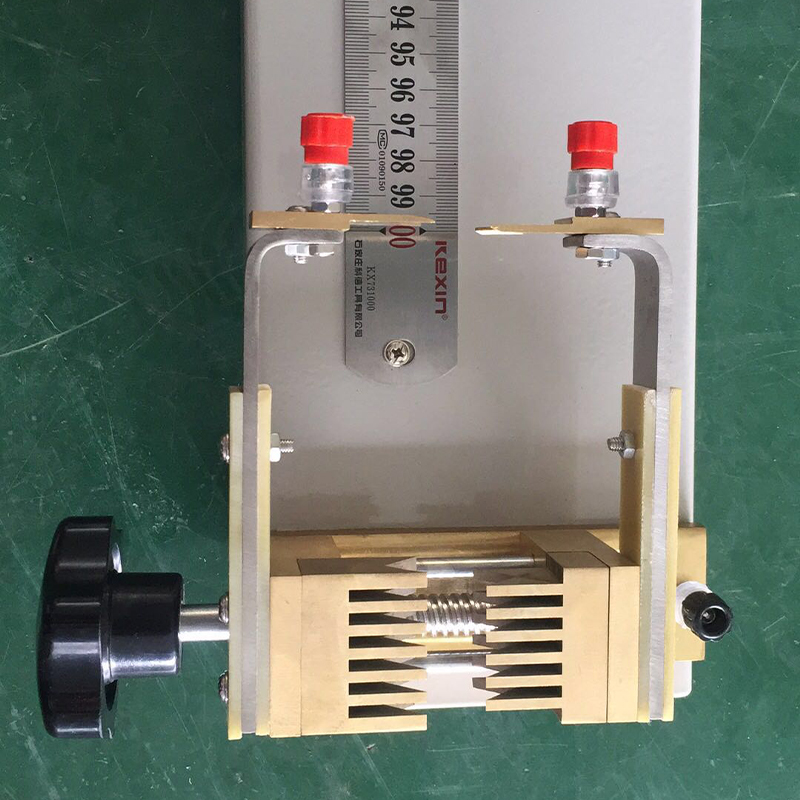

custom universal resistance clamp

Understanding Custom Universal Resistance Clamps A Key Component in Electrical Engineering

In the realm of electrical engineering and power distribution, the significance of reliable and efficient components cannot be overstated. Among these, custom universal resistance clamps play a crucial role in enhancing the performance and reliability of electrical systems. This article delves into what these clamps are, their applications, and the advantages they offer in various industrial settings.

What Are Custom Universal Resistance Clamps?

Custom universal resistance clamps are specialized devices designed to connect electrical conductors in a way that allows for precise resistance measurements. These clamps are essentially connectors that can be adapted to various conductors, making them universal in nature. Their primary purpose is to facilitate accurate testing and monitoring of electrical systems, ensuring that resistance levels are maintained within specified limits.

Applications of Resistance Clamps

These clamps find extensive use in several applications

1. Electrical Testing and Maintenance One of the primary applications of custom resistance clamps is in the maintenance and testing of electrical systems. Technicians utilize these clamps to measure the resistance of various components, such as cables, connectors, and circuit boards. By ensuring that resistance is within acceptable limits, technicians can identify potential issues before they lead to equipment failure.

2. Power Distribution Systems In power distribution networks, resistance clamps are vital for monitoring the condition of electrical connections. They help in the detection of loose or corroded connections that could affect power delivery. By utilizing custom clamps, engineers can tailor the solution to meet the specific needs of the power system, enhancing reliability.

custom universal resistance clamp

3. Renewable Energy With the rise of renewable energy sources such as solar and wind power, the demand for reliable electrical connections has surged. Custom universal resistance clamps are employed in these systems to ensure consistent performance and safety. They are particularly beneficial in environments where standard connectors may not perform adequately.

4. Industrial Equipment In manufacturing and other industrial sectors, equipment downtime can be costly. Resistance clamps are used to conduct regular maintenance checks, helping to prevent unexpected breakdowns. Custom designs can accommodate unique machinery layouts, ensuring seamless integration and operation.

Advantages of Custom Universal Resistance Clamps

1. Versatility The ability to customize these clamps to fit various sizes and types of conductors makes them incredibly versatile. This adaptability is crucial in complex electrical systems where standard solutions may fall short.

2. Enhanced Measurement Accuracy Properly designed resistance clamps enhance measurement accuracy, allowing for more precise testing. This can lead to better diagnostics and maintenance practices.

3. Reduced Downtime By using custom clamps that fit perfectly with the existing infrastructure, companies can reduce maintenance time. This efficiency translates into cost savings and improved operational performance.

4. Improved Safety Accurate resistance measurements help identify potential safety hazards in electrical systems. By detecting issues early, these clamps contribute to safer working environments.

In conclusion, custom universal resistance clamps are essential tools in modern electrical engineering. Their versatility, accuracy, and safety features make them invaluable in a wide range of applications, from maintenance and testing to renewable energy systems. As technology continues to advance, the role of these clamps will likely expand, further cementing their importance in ensuring efficient and reliable electrical systems.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy