custom universal tensile testing machine

Custom Universal Tensile Testing Machine An Essential Tool in Material Testing

In the realm of materials science and engineering, the ability to accurately assess the mechanical properties of materials is crucial. One of the most significant methods used for this purpose is tensile testing, which evaluates the strength and ductility of materials under tensile stress. At the forefront of this testing technology is the custom universal tensile testing machine, a versatile and indispensable instrument tailored to meet a wide range of testing requirements across various industries.

Understanding Tensile Testing

Tensile testing involves applying a controlled force to a material specimen until it deforms or fractures. The results provide valuable data, including the material's yield strength, tensile strength, elongation, and reduction of area. This information is essential for engineers and manufacturers, helping them to determine how materials will behave under different conditions and ensuring that they can meet safety and performance standards.

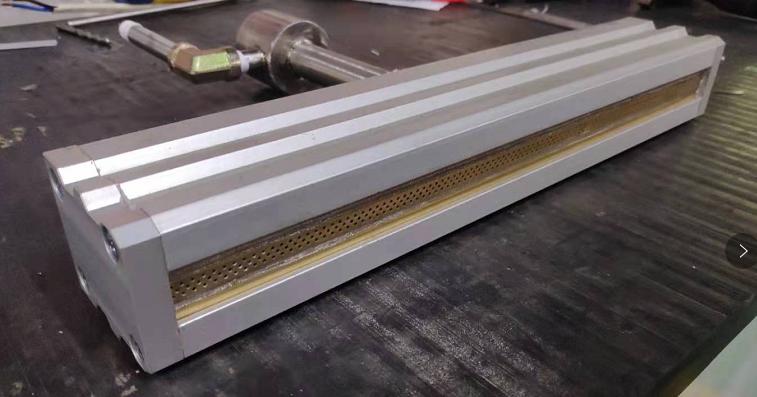

A universal tensile testing machine is designed to perform various tests, including tensile, compression, and bending tests, making it an invaluable asset in research and quality assurance laboratories. The machine is equipped with various grips, fixtures, and extensometers, allowing for customization to fit specific testing requirements.

The Importance of Customization

While standard tensile testing machines are widely available, the need for customized solutions has grown considerably. Different materials—ranging from metals and plastics to composites—exhibit unique characteristics and require specific testing configurations. Thus, a one-size-fits-all approach often falls short, leading to inaccurate results and potential safety hazards.

Custom universal tensile testing machines can be tailored to suit the specific needs of various industries, including aerospace, automotive, construction, and biomedical sectors. This customization may involve adjusting the load capacity, modifying the testing speed, or integrating advanced monitoring systems to capture real-time data during the testing process.

Key Features of Custom Universal Tensile Testing Machines

custom universal tensile testing machine

1. Load Capacity Depending on the materials being tested, custom machines can have varying load capacities. High-capacity machines are essential for testing robust metals, while lower capacities may be more appropriate for delicate components or thin films.

2. Advanced Control Systems Modern tensile testing machines feature sophisticated control systems that allow for precise adjustments to the testing parameters, such as load rate and displacement. This level of control ensures accurate and repeatable results, which are critical for both research and quality control.

3. Data Acquisition Systems The integration of advanced data acquisition systems enables real-time monitoring of the testing process. This feature allows engineers to capture data on material behavior under stress, facilitating more in-depth analysis and insights.

4. Interchangeable Fixtures Custom machines can be equipped with a variety of interchangeable grips and fixtures designed for different materials and specimen geometries. This flexibility enables users to conduct a wide array of tests without needing a separate machine for each material type.

5. Compliance with Standards Custom testing machines can be designed to comply with industry standards such as ASTM, ISO, and DIN, ensuring that results are consistent and recognized globally. This compliance is particularly important for manufacturers aiming for certification and regulatory approval.

Conclusion

The custom universal tensile testing machine plays a pivotal role in the evaluation of materials, providing essential data that drives innovation and improves safety across various industries. With the ability to customize these machines to specific testing requirements, organizations can ensure that they are obtaining accurate and reliable results tailored to their unique needs.

As technology advances, the future of tensile testing will likely see further integration of automation, artificial intelligence, and enhanced data analysis capabilities. This evolution promises to refine material testing processes, making it easier for engineers and researchers to develop new materials and optimize existing ones, ultimately leading to better performance, safety, and sustainability in products and structures. In this landscape, investing in a custom universal tensile testing machine is not just advantageous; it is essential for staying at the forefront of material science and engineering innovation.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy