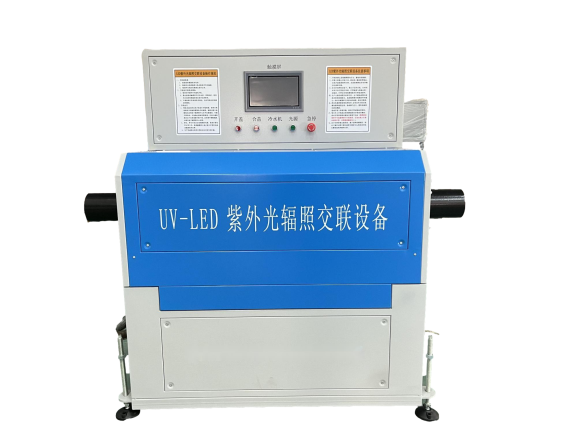

custom uv crosslinking equipment

Custom UV Crosslinking Equipment Enhancing Efficiency in Polymer Processing

In the realm of polymer processing, the significance of UV crosslinking cannot be overstated. This method has gained traction in various industries, including electronics, automotive, and medical, due to its efficiency and the superior properties it imparts to materials. Custom UV crosslinking equipment stands at the forefront of this technology, offering tailored solutions to meet the specific needs of diverse applications.

Custom UV Crosslinking Equipment Enhancing Efficiency in Polymer Processing

One of the key advantages of custom UV crosslinking equipment is its adaptability. Different applications may require specific wavelengths of UV light or different intensity levels. Custom equipment can be designed to cater to these distinct requirements, ensuring optimal crosslinking results. This level of customization is especially beneficial for industries that work with a diverse range of materials and formulations.

custom uv crosslinking equipment

Moreover, with advancements in technology, contemporary custom UV crosslinking systems are equipped with sophisticated controls and automation features. Operators can precisely adjust parameters such as exposure time, intensity, and conveyor speed, allowing for consistent and high-quality output. Such precision not only enhances product quality but also reduces waste, as manufacturers can achieve the desired degree of crosslinking without the need for excessive trial and error.

Safety is another critical consideration in the design of UV crosslinking equipment. Modern systems often include safety features, such as protective enclosures and automatic shut-off mechanisms, to safeguard operators from UV exposure. Furthermore, with a growing emphasis on sustainability, many manufacturers are now focusing on energy-efficient UV systems that minimize energy consumption while maintaining high productivity levels.

The versatility of custom UV crosslinking equipment extends to various substrates, including coatings, adhesives, and inks. For instance, in the printing industry, UV crosslinking can significantly enhance the durability of printed materials, making them resistant to fading and wear. In the medical field, custom UV systems can be employed to create biocompatible coatings for devices, ensuring prolonged lifespan and patient safety.

In conclusion, custom UV crosslinking equipment is revolutionizing the way industries approach polymer processing. By providing tailored solutions that enhance the efficiency, safety, and sustainability of crosslinking processes, manufacturers can achieve higher quality products and improved operational outcomes. As technology continues to advance, the potential applications of UV crosslinking will expand, paving the way for innovative developments across various sectors. Embracing these advancements will be crucial for companies looking to maintain a competitive edge in an ever-evolving marketplace.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy