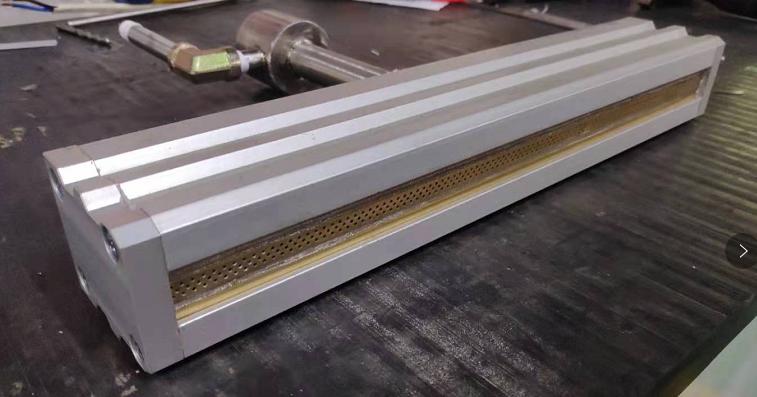

custom winding and torsion tester

Custom Winding and Torsion Tester Innovations in Material Testing

In the world of engineering and material science, the importance of precise testing methods cannot be overstated. Custom winding and torsion testers are essential tools that have gained significant traction in various industries, including aerospace, automotive, and manufacturing. These testers allow engineers to assess the mechanical properties of materials under torsional and winding forces, providing critical data necessary for design and quality assurance.

Understanding the Functionality

A winding and torsion tester is primarily designed to evaluate how materials respond to twisting (torsion) and winding stresses. The tester can be tailored to accommodate different types of materials, including but not limited to metals, polymers, and composites. The core functionality involves applying controlled forces to a sample to measure its deformation under load, which helps determine its strength, elasticity, and overall durability.

Customization for Specific Needs

What sets custom winding and torsion testers apart from standard equipment is their adaptability. Engineers can customize these testers by adjusting parameters such as the torque range, winding angle, speed of application, and sample size. This level of customization ensures that the tests reflect real-world applications of the materials being studied.

For example, in the aerospace industry, components are often subjected to unique stress conditions. A custom tester can simulate the specific torque and winding conditions experienced by parts such as turbine blades or fuselage sections, allowing engineers to anticipate failure points and enhance safety.

Advantages of Custom Testers

1. Precision Custom testers are tailored to meet specific testing requirements, ensuring that the results are as accurate and relevant as possible. This precision is crucial for materials that must meet stringent regulatory standards.

custom winding and torsion tester

2. Versatility Different industries have various material performance criteria. Custom winding and torsion testers can be equipped with various accessories and sensors, enabling them to conduct a wide range of tests. This versatility is essential for research and development, where multiple iterations of testing may be required.

3. Data Collection Modern testers are integrated with sophisticated data acquisition systems that enable detailed analysis. Engineers can collect real-time data during testing, allowing them to analyze how materials behave under different conditions. This data is invaluable for improving material formulations and structures.

4. Cost-Effectiveness While the initial investment in a custom tester might be higher than off-the-shelf solutions, the long-term benefits often outweigh the costs. With the ability to conduct multiple specific tests, companies can save on outsourcing and reduce the time to market for new products.

Applications Across Industries

Custom winding and torsion testers find applications across various sectors. In the automotive industry, they are used to assess the performance of springs, cables, and drivetrains under torsional loads. In manufacturing, they help ensure that materials meet safety and performance standards before they are used in production processes.

In the realm of research, universities and material testing laboratories leverage these custom devices to innovate and develop new materials capable of withstanding extreme conditions. The ability to simulate realistic environmental factors—such as temperature changes or fatigue cycles—provides researchers with the insights needed to push the boundaries of material science.

Conclusion

The evolution of custom winding and torsion testers is a testament to the continual advancements in material testing technology. By providing tailored solutions, these testers are helping engineers and researchers better understand the complex behaviors of materials under stress. As industries evolve and demand for higher performance materials increases, the role of custom winding and torsion testers will become even more critical, paving the way for innovations that enhance safety, efficiency, and performance in a multitude of applications.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy