Custom Winding and Torsion Testing Equipment for Enhanced Performance Evaluation

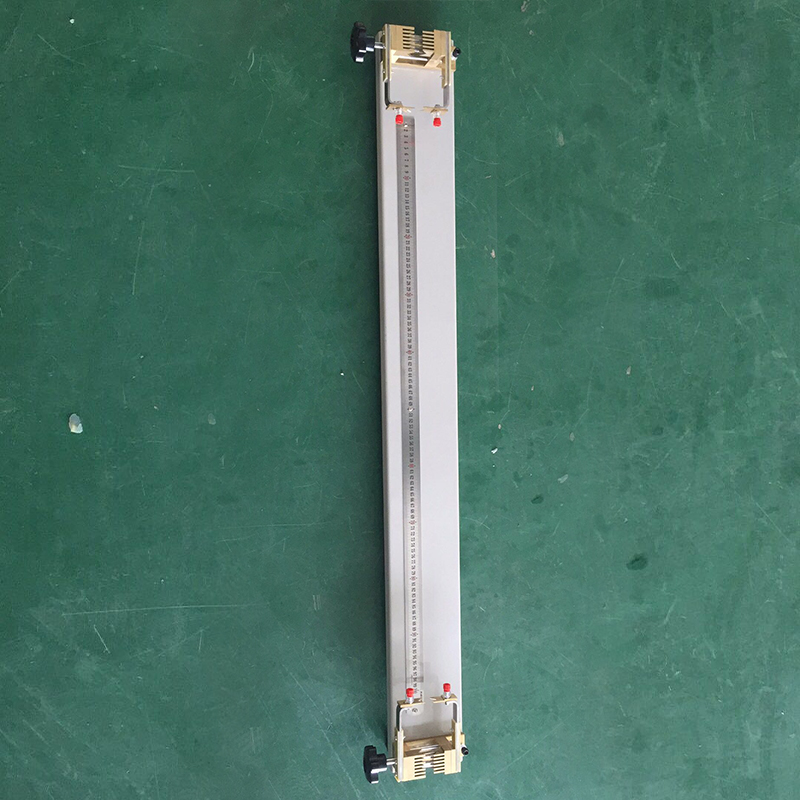

Custom Winding and Torsion Testing Machine An Overview

In the ever-evolving field of materials testing, the demand for precision and customization continues to grow. A custom winding and torsion testing machine stands at the forefront of this trend, providing researchers and engineers with vital tools to evaluate the mechanical properties of various materials, particularly in applications where flexibility and durability are critical.

Understanding the Need for Customization

The diversity of materials used in modern engineering—from composites and alloys to polymers and fabrics—necessitates specialized testing equipment. Traditional testing machines often come with standard capabilities, which may not meet the specific requirements of unique materials or applications. This is where custom machines become indispensable.

A custom winding and torsion testing machine is designed to accommodate the unique characteristics of specific materials

. For instance, materials used in aerospace applications require rigorous testing to ensure they can withstand extreme conditions without failure. Such machines can be tailored to simulate various environmental factors, such as temperature and humidity, thereby providing more accurate and relevant data.Key Features of Custom Winding and Torsion Testing Machines

1. Variable Winding Configurations One of the defining features of a custom winding testing machine is its ability to adapt to different winding configurations. This allows engineers to test materials in the exact manner they will be used in real-world applications. Whether testing fibers, wires, or strips, the machine can be outfitted with custom mandrels and fixtures to ensure proper alignment and tension during testing.

2. Precision Control Systems The accuracy of data obtained from any testing machine is paramount. Custom machines are often equipped with advanced control systems that allow for precise adjustments in speed, tension, and load application. This level of control not only enhances the reliability of test results but also allows for the investigation of material behavior under various conditions.

custom winding and torsion testing machine

3. Integration of Advanced Sensors Modern testing machines often incorporate a range of sensors to monitor the material's response during testing. These may include strain gauges, load cells, and temperature sensors. By integrating these technologies, the custom machine can provide comprehensive data regarding the mechanical properties of the material, helping researchers understand its performance limits and behavior under stress.

4. Data Acquisition and Analysis Software Alongside the hardware, the software plays a crucial role in the functionality of a custom testing machine. Advanced data acquisition systems enable real-time monitoring and analysis of test results, providing engineers with immediate feedback. Custom software solutions can also be developed to tailor analyses to specific customer needs, ensuring that the results are presented in the most useful format.

Applications Across Industries

Custom winding and torsion testing machines find applications across various industries. In the aerospace sector, they are used to test the tensile strength and fatigue resistance of materials used in aircraft components. The automotive industry utilizes similar machines to evaluate the performance of materials that must endure repeated stress, such as springs and suspension components.

In the field of textiles, these machines are vital for assessing the tensile properties of fabrics and fibers, ensuring that they can withstand the demands of everyday use. The construction industry also employs similar systems to test the durability of materials like cables and reinforcements.

Conclusion

The significance of custom winding and torsion testing machines cannot be overstated. As industries push the boundaries of material science, the ability to customize testing equipment ensures that engineers and researchers can gather accurate data, fostering innovation and improving product safety. With advancements in technology, the future of materials testing looks promising, paving the way for stronger, more resilient materials across various applications.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy